There are many brands of CNC machine manufacturers in the world. CNC machinery are high-efficiency automated machine tools composed of mechanical equipment and CNC systems suitable for machining complex parts. CNC machining centers are one of the most productive and widely used CNC machine tools in the world.

CNC machine are called industrial mother machines. They are indispensable equipment in the manufacturing industry and play a vital role in improving production efficiency and product quality. Choosing the right manufacturer is crucial to the success of the project.

There are many brands of machining centers on the market, and there are many options to choose from, so it may be difficult to make a decision during the selection process. The following are the top 15 CNC machine manufacturers in the world compiled by Wuxi Shenchong press brake manufacturer.

DMG MORI is a world-leading CNC machine brand. DMG MORI is a joint venture between Germany's DMG and Japan's Mori Seiki. This brand represents innovation and excellence in machine tool manufacturing, combining the technological advantages of Germany and Japan in machine tool manufacturing to form a global leader in CNC machine tools. DMG Mori Seiki machine tools are well-known around the world and are an important equipment manufacturer for high-end manufacturing.

DMG MORI's products include turning centers and milling centers, as well as advanced processing technologies such as ultrasonic processing, laser processing and additive manufacturing, providing comprehensive automation and digital solutions.

The vertical, horizontal, three-axis, four-axis, five-axis, milling and lathe machining centers, and ultrasonic/laser machining center machine tools produced by DMG Mori Seiki represent the development direction and highest technical level of the domestic and foreign machine tool industry.

DMG MORI cnc machines enjoy a high reputation worldwide. Its products include CNC turning centers, milling centers and advanced processing technologies, etc., aiming to provide comprehensive and excellent technologies for key industries such as aerospace, automobile manufacturing, semiconductors, medical devices and mold manufacturing, and realize the complete digitalization of the entire value chain.

DMG MORI is a world-leading CNC machine manufacturer brand, which is formed by the integration of Germany's DMG and Japan's MORI SEIKI. The DMG MORI brand integrates the advantages of MORI SEIKI for 65 years and DMG for 143 years.

The predecessors of DMG MORI include the three largest machine tool manufacturers in Germany: Decker, Maho and Gildemeister. These companies have a deep technical foundation in the fields of lathes, milling machines and turning and milling machines.

The brand provides comprehensive and excellent technologies for key industries such as aerospace, automobile manufacturing, mold manufacturing and medical devices. With 154 sales and service organizations worldwide, including 15 factories, offices around the world provide services to more than 100,000 customers in 42 industries in 79 countries and regions.

In addition, DMG MORI also launched a new high-precision and high-speed horizontal machining center - NHC 5500 for the first time in the world. This machine tool has the characteristics of high speed and high precision, and is suitable for industries such as machinery manufacturing, automobiles, hydraulics, and engineering machinery. It can efficiently mass-produce a variety of products.

Japan Yamazaki Mazak (MAZAK) is a world-renowned cnc machine manufacturer, with a market share that ranks first all year round. The company was founded in 1919.

MAZAK mainly produces CNC lathes, compound turning and milling machining centers, vertical machining centers, horizontal machining centers, CNC laser systems, FMS flexible production systems, CAD/CAM systems, CNC devices and production support software, etc.

The Mazak Smooth system uses Mazak's seventh-generation CNC system. Both the software and hardware configurations are brand new, and are specially designed to cope with the intelligent platform in the era of the Internet of Things. It can achieve high-speed, high-precision, and high-quality processing. In addition to Smmoth technology, Mazak also has a unique device - a CNC device dedicated to compound processing machines, 5-axis processing machines, machining centers, and CNC lathes.

Mazak has a very high position in the global industry. It is the best supplier of CNC machine equipment for the Boeing Group and an important supplier of Russian military enterprises.

MAZAK machine tools are well-known in the industry for their high speed and high precision. With the continuous development of manufacturing technology, automation and digital technology, its products are used in various industries of the machinery industry. Its customers are mainly distributed in different industries such as automobile, machinery, electronics, energy, and medical.

Founded in 1908, Mikron is a high-precision CNC machine manufacturer headquartered in Switzerland. It produces a variety of high-end machining centers and universal lathes, covering a variety of machining applications from manual to fully automatic.

MIKRON produces various types of machine tools to provide the right and ideal solutions for every customer's problems encountered in the machining process.

To this end, Mikron makes full use of its best innovative technologies, research, development results and engineering technology capabilities, excellent engineering skills and production centers in Nidau, Switzerland, as well as a nationwide sales center network and worldwide service center support.

As a member of the Agie Charmilles Group, Mikron focuses on the development, manufacturing and sales support of high-performance machining centers and high-speed milling machines.

Mikron's milling technology has always been world-renowned. Mikron machine tools have very advanced thermal stability, which can ensure reliable high precision during long-term machining.

Another highlight is Mikron's unique all-directional spindle collision protection technology (MSP), which can prevent spindle collision failures. Automation solutions can be integrated to bring the production capabilities of precision component manufacturers and mold manufacturers to a new level.

Makino is a Japanese company. It was founded in 1937 and is headquartered in Tokyo, Japan. Makino is a global industry-leading cnc machine manufacturer with a long history. MAKINO is the first machine tool manufacturer in Japan to produce CNC milling machines and machining centers.

Makino machining centers have an excellent reputation in the field of precision molds and parts manufacturing, from three-axis to five-axis, from vertical to horizontal, from micro-machining to large-scale. There are corresponding products.

The application areas of Makino machine tools are mainly molds, parts processing and aerospace. The mold industry is the largest application area of Makino machine tools, accounting for more than 60%.

In recent years, Makino has developed a series of high-precision and high-speed five-axis machine tools to meet market demand. The precision of five-axis machine tool linkage processing is comparable to that of three-axis machine tools. Even the iQ500 machine tool with a larger stroke has achieved breakthroughs in ensuring that the high-precision requirements of μm level are met.

Makino implements its consistent philosophy globally: high precision, high efficiency and high stability, ensuring that consistently high-quality products are produced in all regions. From the Makino V33i vertical machining center, the "ace model" that has been popular in the mold industry for more than 20 years, to the iQ300 high-precision vertical machining center and then to the V80S large five-axis vertical machining center, it fully reflects Makino's design concept of meeting user needs and its high-efficiency, high-precision and high-performance product features.

The origin of Chiron machine tools can be traced back to 1921. It is located in Tuttlingen, Germany. It started out by manufacturing surgical instruments, instruments, and instrumentation products.

Since 1958, Chiron has entered the machine tool industry and focused on the research and manufacture of CNC vertical machining centers. It has gradually developed into one of the brands with the fastest and best machine tool equipment in the world.

Chiron has always insisted on innovation and maintained its leading position, from the manufacturer of medical equipment in its early years to the manufacturer of compressors in the 1950s to the manufacturer of high-speed CNC machine tools today. Chiron's machine tool products are famous for their high-precision technology and excellent performance, and are one of the representatives of German high-end machine tools.

For example, the MILL FX800 five-axis high-speed vertical machining center is a true five-axis five-linkage machining center, especially suitable for the aerospace and automotive parts manufacturing fields.

Germany Chiron Group is a global expert in the research and development, manufacturing and turnkey solutions of vertical CNC machining centers and turning centers. It is known worldwide for its high-efficiency and high-quality complex workpiece processing at the lowest unit cost. It is worth mentioning that CHIRON has become a benchmark for high performance and high precision in the global machine tool industry, with the world's fastest tool change system, efficient production solutions and automation technology.

For example, the German CHIRON vertical machining center has single-spindle, dual-spindle, and four-spindle vertical machining centers. It is very different from the tool change methods we usually see. Usually, we see the hat-shaped disc type and chain type. CHIRON has an independent manipulator on each tool handle and has a greater improvement in tool change time. It only takes 60 seconds to make a car wheel!

Such advanced equipment is mainly used for high-precision parts, such as car engines, steering shafts, and other complex parts, especially turnkey projects.

Okuma was founded in 1918 in Japan. It is an integrated supplier of machine tools and control devices. It is a comprehensive enterprise mainly engaged in the research and development, production and sales of machine tools and CNC systems.

Japan Okuma is the largest CNC machine manufacturer in Japan and the largest gantry machining center manufacturer in the world. It has a history of more than 100 years. It produces various CNC lathes, turning centers, vertical, horizontal, gantry (pentahedron) machining centers, CNC grinders, etc.

Japan Okuma Corporation is one of the largest CNC machine tool manufacturers in Japan. It has a history of more than 100 years. It mainly produces general CNC lathes and machining centers, and independently develops and produces OSP CNC devices. The products are known for their good rigidity, high efficiency, stable precision, long life and easy operation.

OKUMA is the only CNC system in the world that is independently developed by a machine tool factory. It is its own CNC system, similar to Apple computers. Because it is developed by the machine tool factory itself, very practical.

Products include horizontal and vertical CNC lathes/turning centers, vertical and horizontal machining centers, gantry machining centers, vertical and horizontal compound processing machines, oil pipe processing machines, wheel hub processing machines, CNC internal and external cylindrical grinders.

Japan's Okuma products are famous for their good rigidity, high cutting efficiency, high precision, long life, and easy operation, and are well received by users all over the world. Okuma CNC system is an industry benchmark in Japan. It is a comprehensive and practical CNC system. Many functions are modular (i.e. optional functions) and are highly targeted.

Usually when using a machining center for machining operations, it is hoped that the machining operations are carried out in a unified machining coordinate system. However, in some machining situations, using some coordinate transformation techniques combined with subroutine call instructions can make machining programming simpler and easier.

Japan's Okuma Corporation is not only a world-renowned CNC machine tool manufacturer, but also began to develop Okuma's own CNC system-OSP CNC device as early as the 1960s.

With an annual output of more than 7,000 CNC devices and about 30,000 spindles and servo motors, it once ranked around 5th in the world. The OSP system is not only advanced, stable and reliable, but also practical and easy to operate. It is fully integrated with the machine tool and truly achieves mechatronics.

Japan's Okuma is one of the few "all-round manufacturers" in the world's machine tool industry. For decades, it has insisted on independently designing and developing everything from core components (drivers, encoders, motors, spindles, etc.) to CNC operating systems to terminals, truly achieving both software and hardware.

In particular, OKUMA's five-axis machining center can maintain high-precision 5-axis machining for a long time through the synergy of the "5-Axis Auto Tuning System" that maximizes machining accuracy and the "Thermo-Friendly Concept" that maintains machining accuracy.

OKUMA can achieve processing of various discs, plates, shells, molds, etc., and is suitable for other processing in the automotive parts, electrical instruments, tools, hardware and other industries. It can also be used for efficient processing and manufacturing of small and medium-sized batches of parts, and its characteristics are more prominent in complex and high-precision processing.

Hermle was founded in 1938 and is one of the most famous CNC machine brands in Germany. The five-axis vertical machining center occupies a leading position both in Germany and internationally.

Hermle's five-axis vertical machining center is in a leading position in the international market, and the factory is located in Gosheim near Stuttgart, Germany. Today, more than 20,000 universal milling machines and machining centers produced by Hermle are used worldwide. Hermle's reliable product quality and excellent after-sales service ensure that Hermle has become a trusted partner of customers.

The worktable of Hermle products has a large swing angle and good dynamic performance, which is suitable for complex surface processing (including negative angle processing). The machine tool's high geometric accuracy and position accuracy are suitable for high-precision parts processing, especially parts processing with high hole position accuracy (parallelism, repeatability). The machine tool has stable performance and good long-term accuracy retention.

Hermle produces about 1,000 machining centers annually, of which 80% are five-axis machining centers. Therefore, its advantage is also in 5-axis processing.

Machine tool manufacturing is higher than the DIN/ISO 10791 standard in many aspects. Whether it is high-demand milling or milling-turning synchronization, it can be achieved with the combination of integrated swing axis and rotary axis and high-efficiency torque motor. Therefore, it has great advantages in flexibility.

Hammer is an expert in small and medium-sized five-axis precision machining. Hammer's products have extremely obvious advantages in complex surface machining, negative angle machining, high-precision machining and high-speed machining. Hammer ranks first in the market share of five-axis machine tools for small and medium-sized mold manufacturing in Germany. The high rigidity of the machine tool is particularly suitable for the machining of thin-walled parts.

Hammer's five-axis linkage series machining center is familiar with the production of key components in the automotive industry, racing industry, energy technology, molds, aerospace, medical engineering, and tool technology with its excellent dynamic performance, reliable machine tool stability, original spindle anti-collision function, gantry frame marble bed, and effective anti-thermal deformation design in the field of high-precision, high-efficiency and high-reliability production.

Press Brake Bending Machine Latest Buying Guide

Since its establishment in Munich in 1926, GROB has gradually grown into an international family-owned enterprise that develops and produces equipment and machine tools. Their customers are world-renowned automobile manufacturers, their suppliers and other well-known companies from all walks of life.

GROB's products cover everything from general machining centers to highly flexible and highly automated production systems, from assembly units in mechanical processing to fully automated assembly lines. In addition, motor production equipment, battery and fuel cell technology assembly equipment are also included in the product range.

Strong technical strength, strong innovation ability, outstanding processing depth, and excellent quality reliability all demonstrate GROB's extraordinary brand strength.

GROB also has thermal spraying technology suitable for engine components, and can also provide customized solutions for the processing of turbine housings, frame structure workpieces, chassis workpieces and battery housings.

Under the framework of Industry 4.0, GROB has taken an important step and launched GROB-NET4Industry software for comprehensive future-oriented digital and networked production. In addition, GROB has successfully entered the field of additive manufacturing and developed a new liquid metal printing equipment.

YASDA Japan was founded in 1929 and is a professional manufacturer specializing in the production of coordinate machining centers and precision machining centers.

Initially, Yasuda Industry was engaged in the production and manufacturing of automobile engine honing machines. In 1964, YASDA started with the development of the horizontal precision boring and milling machine "JIG MASTER".

Since then, Yasuda Industry has officially entered the machine tool industry. In 1966, Yasuda Industry developed Japan's first horizontal machining center.

YASDA Japan is an outstanding representative of high-precision machining center brands, pursuing ultra-high precision of sub-micron precision. "Not seeking the largest but the best" is the basic concept of YASDA.

Its products are suitable for optical molds, semiconductor processing, high-hardness quenching processing (HRC65), high-precision multi-cavity molds, and high-finish processing molds.

YASDA Japan does not blindly expand the scale of the enterprise, but challenges the development of the ultimate products required by the times at any time, so as to organize the development of ultra-high-precision machine tools.

The preload automatic adjustment type high-speed spindle developed by YASDA has a large preload at low speed, and automatically adjusts the preload according to the heat generated by the bearing at high speed. It realizes heavy cutting at low speed and high-precision rotation at high speed with low heat generation.

Haas Automation is one of the world's largest CNC machine manufacturers. The production base is located in Oxnard, California. As early as 2006, the annual output of Haas CNC machine tools reached more than 12,500 units, becoming a milestone in the CNC machine tool industry.

Haas VF-1 vertical machining center has established an industry benchmark for high quality and high cost performance. The excellent Haas CNC system makes the operation of the vertical machining center handy, and is equipped with intuitive functions that other brands of machine tools do not have.

It is worth mentioning that Haas is also the only machine tool industry that truly achieves completely transparent prices. Haas uses its own system. The latest system is Series 16. The Haas system is compatible with FANUC and Mitsubishi programs.

It is the leader in the global small and medium-sized machining market, occupying almost 80% of the market share in Europe and the United States. Especially in the military field, there are many applications. Almost all small precision machining in the military field in Europe and the United States is covered by this machine tool factory.

EMAG Group was founded in 1867. The headquarters is located in Salach near Stuttgart, Germany. EMAG Group's business is mainly distributed in the automotive manufacturing and supporting industries, machinery manufacturing industry and aerospace industry, renewable energy, power and oil industries.

EMAG Group focuses on the field of inverted automatic loading and unloading turning machine tools. EMAG Group provides machine tools and production systems for processing disc parts, shaft parts and box parts, inverted lathes and inverted multi-functional production centers.

EMAG machine tools have machine tools for turning, drilling, boring, milling, grinding, hobbing and laser processing. EMAG Group's products cover the processing of two-thirds of circular and non-circular parts in automotive parts.

EMAG's vertical machining center can process complex geometries and parts with larger diameters. Vertical CNC machining centers can be equipped with a variety of different processing technologies and provide extremely high flexibility.

The inverted machine tools developed by EMAG and the automatic integrated system shorten the loading and unloading travel and the workpiece processing cycle, contributing to the production requirements of improving efficiency and reducing costs.

At the same time, high quality and high efficiency are also two convincing factors. In addition, the automatic integrated system and its ergonomic design concept make EMAG machine tools simple and intelligent in operation, reduce the burden on employees, and improve safety and comfort at work.

Doosan Machine Tools established a production base in Changwon, Korea in 1976. In 1979, the total production of machine tools exceeded 1,000 units.

Since the development of the Korean overseas market in 1981, the Doosan Engineering Machinery Division and the Doosan Machine Tool Division. They were divided into two companies, were merged on January 1, 2007, thereby enhancing the competitiveness of the machine tool business and laying a solid foundation for the development into a global leading enterprise.

High-speed CNC tapping machining center: high-speed linear guides and high-speed servo motors ensure high-speed axial speed, shorten non-processing time, high efficiency, high precision, and high economy. This series includes DT400.

High-production vertical machining center: high-rigidity guide rails, high-performance and high-precision standard new models, with long-term accuracy retention and ultra-precision surface processing performance, high durability can create extraordinary value. This series includes CMV920, Mynx545, Mynx545/50, Mynx650, Mynx650/50.

High-speed heavy-load vertical machining center: designed for high-speed and high-load machining, powerful, heavy-load structure and high rigidity guarantee. This series includes V435.

Economical horizontal machining center: an economical horizontal machining center integrating high speed, high precision and high reliability, with high reliability and spacious working area, easy workpiece adjustment, and double pallet exchange structure greatly reduces the workpiece clamping time and improves work efficiency. This series includes HC505.

High-rigidity heavy-cutting horizontal machining center: heavy-load, high-rigidity guide rails, powerful cutting, powerful spindle drive mode, stable position accuracy and repeat positioning accuracy. This series includes HM635 and HM805.

Doosan Machine Tools of South Korea is committed to adjusting itself into a truly global manufacturer with a new name by strengthening its unique competitive advantage in the current growth engine. And actively establish a presence in future growth areas through active investment to expand manufacturing capabilities and sustainable management of social responsibility. Doosan machine tools are exported to markets such as the United Kingdom and Italy, and its global market share ranks 15th.

The high-quality machining centers independently developed, designed and manufactured by Matsuura Machinery are widely used in all industries in the world today, such as aerospace, automobile, motor, sports, precision machinery, communications, medical research, etc.

Since the company was founded in 1935, Matsuura Machinery has been adhering to the enthusiasm and spirit of the beginning of its entrepreneurship, constantly challenging the world's leading technology in the field of production. And it continues to expand its overseas business and gradually forms an international professional group.

In March 1974, the world's first vertical machining center was born in Japan. The price was only 16 million yen. It was immediately welcomed by small and medium-sized enterprises.

The main products include vertical machining centers, horizontal machining centers and vertical cradle-type five-axis machining centers.

Japan Matsuura Machinery is a long-established manufacturer of vertical machining machine tools in Japan, and the manufacturer of Japan's first vertical machining center and vertical cradle-type five-axis. As a high-precision mother machine, Matsuura equipment is widely used in the production of small batches of multiple varieties.

Matsuura has won high praise from customers for its highly reliable and stable product quality, the latest processing applications, and after-sales services.

The Starrag Group is a global leading manufacturer of high-precision CNC machines, whose products are mainly used for milling, turning, boring and grinding of metal, composite and ceramic workpieces.

Starrag Group is headquartered in Rorschach, Switzerland, and has production bases in Switzerland, Germany, France, the United Kingdom and India, and has established a network of sales and service subsidiaries in many other countries.

The main products include horizontal machining centers, vertical machining centers, blade and integral blisk machining centers, gantry machining centers, etc. The main customers are companies engaged in international business activities in the fields of aerospace, energy, transportation and industry.

In addition to the machine tool series, the Starrag Group also provides integrated technology and maintenance services, which significantly improves customer productivity.

The 10 brands under the Starrag Group have accumulated more than 900 years of mechanical engineering expertise and experience over the years.

Starrag Group is a leading manufacturer of complete solutions for efficient and durable precision cutting applications. Innovation, quality, global influence and customer service capabilities ensure that our customers always maintain an advantage in productivity.

Hurco was founded in 1968. Its headquarters is located in Indianapolis, the capital of Indiana, USA. It is a global industrial technology company and a leading CNC machine manufacturer. It has 12 independent wholly-owned subsidiaries worldwide and is a NASDAQ-listed company.

Main products include vertical machining centers, five-axis machining centers, turning machining centers, etc. The first American Hurco machine tool was launched in 1978. So far, there are more than 30,000 Hurco CNC machine tools in the world.

Hurco has the world's most advanced and intuitive intelligent control system (Winmax control system independently developed). In addition, its rich machine tool products can help users optimize metal processing process.

For more than 40 years, Hurco's intelligent CNC technology has been in a leading position in the machinery manufacturing industry, with 60 valid patents in 15 countries.

Hurco has a complete product line, global engineering and manufacturing, a global marketing network and convenient and fast regional services, rigorous manufacturing processes, a transparent and healthy financial system and a professional management team. These have become Hurco's core competitiveness. Hurco strictly follows German design standards for manufacturing and quality control, and adopts VDI3441 standards for precision inspection, which can ensure the long-term precision stability of machine tools.

Other manufacturers ranking summary:

Top 15 Plate Bending Machine Manufacturers in the World

The World’s Top 8 Plate Rolling Machine Manufacturers

TOP 8 CNC Plate Bending Machine Manufacturers in Asia

TOP 8 Laser Cutting Machine Manufacturers

Top 8 Sheet Metal Shear Machine Manufacturers

Top 9 Sheet Metal Automation Equipment Manufacturers in Europe

Top 6 Press Brake Manufacturers in Egypt

Top 7 Press Brake Manufacturers in Saudi Arabia

Top 7 World-Famous Groove Machine Manufacturers

After the workpiece clamped once on the machining center, the digital control system can control the machine tool to complete multiple processes on several surfaces of the workpiece in sequence according to different processes.

The functions include automatic selection and replacement of tools, automatic change of machine spindle speed, feed rate, and the relative motion trajectory of tools to the workpiece, as well as other auxiliary functions. And there are multiple tool changing or selection functions, which greatly improve production efficiency.

In today's manufacturing industry, cnc machines play a vital role. Whether it is mechanical manufacturing, automobile manufacturing or electronic equipment manufacturing, high-quality machining centers are needed to ensure the precision and quality of products.

At present, there are many brands of cnc machines on the market. When customers purchase machining centers, they don't know how to choose the right machining center brand. Wuxi Shenchong will provide you with a comprehensive guide to help you choose a high-quality machining center.

First, you need to clarify your needs.

- What kind of material do you need?

- How high a precision do you need?

- What kind of surface treatment do you need?

- What kind of production cycle do you need?

Understanding your needs is the first step in choosing a machining center. Only by clarifying these needs can you choose the right machining center in a targeted manner.

It is also very important to choose a CNC machine manufacturer with strong production capacity. Manufacturers with strong production capacity usually have more production equipment and more production lines, which can better meet customer needs and ensure the accuracy of delivery time.

It is also very important to choose a CNC machine manufacturer with strong technical strength. Manufacturers with strong technical strength can better meet customers' customization needs and provide better after-sales service. You can understand its technical strength by checking the manufacturer's production qualifications, equipment configuration, technology research and development, etc.

It is also very important to choose a CNC machine manufacturer that provides high-quality after-sales service. The quality of after-sales service is directly related to the customer's production efficiency and production cost. You can understand the quality of its after-sales service by asking the manufacturer's after-sales service policy, customer feedback, etc.

It is also very important to choose a CNC machining center manufacturer with reasonable price. Manufacturers with reasonable price can help customers reduce production costs while ensuring product quality and delivery time. You can choose the most suitable manufacturer by comparing the prices and product quality of multiple manufacturers.

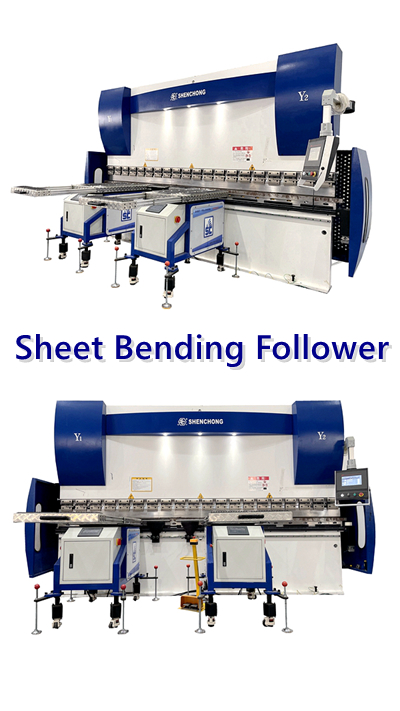

100KG Sheet Follower The Best Price: 5,000 USD Big Discount 30%OFF