How water jet cutting works? Water jet is an efficient and precise cutting tool, widely used in industrial manufacturing, especially in situations where different types of materials (such as metal, stone, glass, plastic, wood, etc.) need to be cut without heat effects. The working principle, composition and application range of water jet are very wide. The following is a detailed introduction to various aspects of water jet:

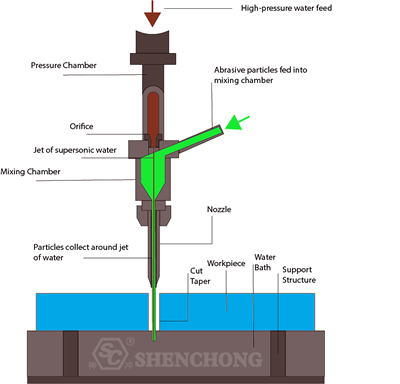

The basic working principle of a water jet is to cut with high-pressure water. When water is pressurized to a certain pressure by a special high-pressure pump, the water is directed into a nozzle and ejected to form a high-speed water stream. The impact and friction of this water stream can directly penetrate and cut various materials.

Usually, a water jet system pressurizes water to 4000-6000 bar (about 60,000-90,000 psi) through a high-pressure pump, and then ejects it through a very fine nozzle (usually 0.1-0.2 mm). The water stream can reach the speed of sound, up to 600 meters per second.

The speed of the water flow and the design of the nozzle are crucial, which determines the effect and accuracy of cutting. The size of the nozzle directly affects the pressure and speed of the water flow, which in turn affects the cutting effect.

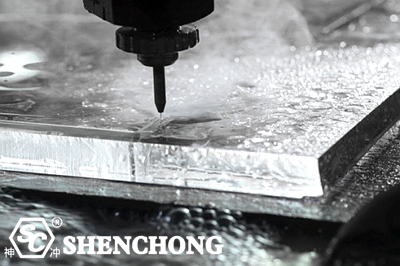

When the high-speed water flow is sprayed onto the surface of the material, the impact force of the water flow will destroy the surface of the material and gradually cut the material. When the water flow is mixed with abrasives, the cutting ability of the water flow will be stronger, which is suitable for cutting hard materials.

The core principle of water jet cutting is to use high-speed, high-pressure water flow to cut objects with the help of the impact force of water and the grinding force of abrasives. Specifically, the process of water jet cutting can be divided into several steps:

The water jet uses a high-pressure pump to pressurize water to several thousand bar (1 bar equals 1 atmospheric pressure, and the working pressure of the water jet is usually between 4000-6000 bar), and then ejects the high-pressure water through the nozzle. When the water flows through the nozzle, the speed can reach the speed of sound (about 600 meters per second), and this high-speed water flow has a strong impact.

When high-speed water hits the surface of a material, it generates a very strong physical impact force, quickly penetrating the surface of the material, causing the material to break or cut. Water jets can penetrate many brittle or soft materials (such as paper, plastic, wood, etc.), and can also effectively cut hard materials such as metal and stone, especially when abrasives are added to the water flow.

In order to cut hard materials (such as metal, ceramic or stone), water jets often add abrasives (such as aluminum sand, garnet, etc.) mixed with water. The abrasive is ejected at high speed along with the water flow, and hits the surface of the object together with the water flow, making the cutting more effective through friction and grinding. The addition of abrasives makes water jet cutting not only rely on the impact force of the water flow, but also rely on the grinding effect of the abrasive.

Under the combined action of high-speed water flow and abrasive, the surface of the material will be broken or cut, resulting in a fine cutting surface. During the cutting process, since the water jet does not generate high temperature, the cutting area will not be affected by heat, and thermal expansion or thermal deformation will not occur, which is especially important for some heat-sensitive materials (such as certain metal alloys or precision parts).

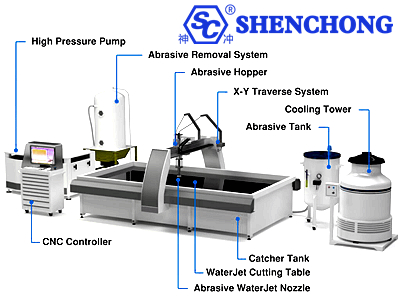

Modern water jet cutting machines are usually equipped with CNC control system that can accurately control the jet direction and cutting path of the water jet. This enables the water jet to perform very fine cutting and even cut complex graphics and shapes.

In summary, water jet cutting uses high-speed, high-pressure water (sometimes mixed with abrasives) to impact and rub materials, thereby achieving efficient and precise cutting. Since it does not generate heat, water jet cutting is very suitable for precision cutting, especially when processing heat-sensitive materials.

The composition of the water jet is relatively complex, mainly including the following core parts:

Responsible for pressurizing water to the required high pressure. Common high-pressure water pumps include piston pumps and plunger pumps, which can withstand pressures up to 6000 bar.

Pressure regulating system: used to adjust the pressure of the water flow to ensure the stability of the water pressure during cutting.

The nozzle is one of the core components of the water jet, responsible for ejecting high-pressure water. The design and aperture size of the nozzle determine the speed of the water jet and the cutting accuracy.

It includes electronic control system and mechanical control system, which are used to accurately control the jet direction, jet time and cutting path of the water jet. The CNC control system can provide very high cutting accuracy.

If you need to cut materials with higher hardness (such as metal, stone, etc.), abrasives (such as garnet, aluminum sand, etc.) are usually added to the water flow through a conveying system. The water and abrasive are mixed and ejected together through the nozzle to enhance the cutting effect.

The water jet requires a system that continuously supplies water. The water tank provides a clean water source. At the same time, some systems also have water filtration devices to ensure clean water quality.

The workbench is where the material to be cut is placed. It is usually a flat surface or a height-adjustable bracket. The positioning system helps to position the material accurately to ensure cutting accuracy.

Water jet cutting technology has many advantages that make it widely used in many industries:

Water jet cutting does not generate heat, thus avoiding material deformation, stress concentration or physical property changes that may be caused by high temperature. It is particularly suitable for heat-sensitive materials such as metals, plastics and composites.

Water jet can achieve fine cutting, smooth cutting surface, and almost no subsequent processing is required. The accuracy can usually reach ±0.1mm or even higher.

Water jet can cut almost all materials, including metal, stone, ceramic, glass, plastic, rubber, wood, paper, etc., and can even handle very thick materials.

Water jet can cut according to any design pattern, can accurately cut complex shapes, and is suitable for complex two-dimensional and three-dimensional graphics cutting.

Water jet uses water and recyclable abrasives, and almost no exhaust gas and harmful substances are generated during the cutting process, which is environmentally friendly.

Water jet cutting is widely used in many industries, especially in areas that require cutting accuracy and no heat effect. Common applications include:

Water jets are widely used to cut various metal materials, such as aluminum, copper, stainless steel, titanium alloy, etc. It is particularly suitable for cutting precision parts.

Water jets can accurately cut marble, granite and other stones, and are often used in the construction and carving industries.

In the automotive and aviation fields, water jets are used to cut complex parts, such as engine parts, transmission system parts, etc., avoiding the heat effects that may be caused by traditional cutting methods.

Water jet cutting can be used for the manufacture of delicate circuit boards, displays and other electronic components.

Cutting of paper, cardboard and other packaging materials.

Water jets are also used to cut certain foods, such as bread, candy, etc., which can be cut quickly and without contaminating food.

Although water jet has many advantages, it also has some limitations:

Compared with laser cutting, plasma cutting and other methods, water jet cutting speed is slower, especially for thicker materials.

Water jet system usually requires larger equipment space, and the equipment itself is bulky.

Water jet equipment requires regular maintenance, especially parts such as nozzles and high-pressure pumps. The use of abrasives also requires additional consumption.

Although water jet can cut thicker materials, for materials above a certain thickness, the cutting effect of water jet will decrease and the efficiency will become slower.

With the continuous advancement of technology, water jet cutting machines are also developing:

With the development of industrial automation, more and more water jet cutting machines have adopted more advanced numerical control systems (CNC), achieving higher cutting accuracy and efficiency.

By studying more efficient nozzles and new types of abrasives, the cutting effect and efficiency of water jets will be further improved.

Water jet technology itself has environmental advantages, but there will be more technological breakthroughs in the future to reduce the waste of water resources and improve the recycling rate of water.

How water jet cutting works? In general, water jet is a very efficient, environmentally friendly and precise cutting technology that has played an important role in many industries, and with the advancement of technology, the application field of water jets will continue to expand and the technical performance will continue to improve.