When purchasing a plate rolling machine, we need to choose a plate rolling machine manufacturer. We usually worry about whether the plate rolling machine manufacturer is regular and safe.

In order to solve the doubts of buyers, we specially went online to collect information about the top 8 plate rolling machine manufacturers in the world as well as user evaluations of these rolling machine manufacturers. Hope this helps all bending roller machine users!

Plate rolling machine manufacturers are companies that produce and sell plate rolling machines (also called bending rollers, plate bending machines, roll bending machines, etc.). These manufacturers usually provide plate rolling machines of different types and specifications to meet the curling processing needs of various metal plates (such as steel plates, stainless steel plates, aluminum plates, etc.).

Let's take a look at the overview of the top 8 plate rolling machine manufacturers in the world and the analysis of bending roller products.

SHENCHONG Co., Ltd. is one of leading metal plate rolling machine suppliers and manufacturers in China. It has rich experience in production and sale of 3 or 4 roller plate rolling machines. Shenchong NC/CNC hydraulic rolling machine for sale is widely used in shipbuilding, boiler, aviation, bridge, metal structure and other manufacturing industries.

5 types of 3 rollers plate bending machine:

Mechanical Symmetry Three-roller Bending Machine

Shenchong three roll symmetrical plate bending machine is an efficient, easy to operate and intelligent rolling equipment. Simple structure. Easy to operate.

The machine is mechanically symmetrical three roll type. The upper roll moves vertically up and down at the symmetrical center of the two lower rolls. The two lower rollers are driven by the screw, nut and worm to rotate. The output gear of the reducer is meshed with the lower roll gear to provide torque for rolling plates.

The disadvantage of this machine is that the plate end needs to be pre bent with other equipment.

Mechanical level down three-roller bending rolls

Shenchong mechanical level down three roll bending machine is an easy to operate intelligent metal bending equipment.

It successively constitutes two types of asymmetric three roll plate bending machines. From thin plate to thick plate, from pre bending end to rolling round, the whole process is completed at one time.

The advantage is that it is very convenient to roll the cone.

Asymmetry 3-roller bending machine

This equipment is an asymmetric three roll plate bending machine. It is used to roll metal plates of certain thickness into cylindrical and arc shapes at room temperature. Pre bending and coiling can be carried out without additional equipment.

Its working principle is roll bending deformation. The pre bending straight edge of eccentric three roll bending plate is small. The rolling accuracy is high. Easy to operate.

This plate bending machine is a necessary equipment for boiler, shipbuilding, petrochemical, cement, motor and other machine manufacturing industries.

Upper roller universal three-roller bending roll

The upper roll of SW11SNC upper roll universal three roll plate bending machine can move up and down and horizontally. The upper roll moves up and down to change the curvature of the bending plate.

The forward and backward movement of the upper roll is used to change the vertical symmetrical position of the upper roll to the axis lines of the two lower rolls. Thus, the end bending of sheet metal can be realized and the process requirements for various bending can be met.

No additional equipment such as press is required in the production process. After one feeding, the pre bending and forming functions of both ends of the sheet can be completed without turning the sheet, and it can also be used for the correction of formed workpieces.

Shipbuilding Large sheet metal rolling machine

Shenchong shipbuilding bending machine is specially used for bending the hull arc. Advanced design. Compact structure. High strength. Easy to operate. Stable operation. Reliable quality. Plate rolling machine factory direct sales. Reasonably price.

4-roll CNC plate rolling machine

Four roll plate bending machine is a metal plate bending and correcting machine. It is specially used for sheet metal forming and bending.

The machine can complete the pre bending of the end of the plate and the rolling of cylindrical and arc workpieces with one feeding. The metal sheet can also be roughly reshaped.

It is widely used in shipbuilding, boiler, aviation, bridge, hydropower, chemical industry, metal structure, machinery manufacturing and other industries.

The pre bending straight edge is small, the roundness of the round calibration is good, and the tapered workpiece can be rolled by the full generatrix.Strong ability to roll small circles. This is the most efficient and capable universal plate rolling machine.

- The shape and color matching of the Shenchong plate bending rolls are not excellent as those of European and American manufacturers. The appearance is simple and common.

- Specializing in the production and sale of sheet metal rolling equipment. Not much involved in the field of angle steel rolling machine and pipe bending roll.

- Although not so delicate in appearance, Shenchong rolling machine is good in performance and use.

- Reasonable prices with discounts.

- Offer various kinds of sheet rolling machines. Different types for different customers to choose.

- Shenchong three roller bending machine can roll up sheet metal from 6mm to 100mm thickness. Four roller bending machine is more intelligent and continent.

- The large shipbuilding sheet rolling machine is a hot product and very popular with shipbuilders all around the world.

- Introduced advanced technology and concept from Europe. Choose SHENCHONG, you can enjoy the experience of high quality rolling process at a relatively low price.

FACCIN is the leading plate bending rolls manufacturer in Italy. It has more than 50 years’ experience in the design, production and sale of sheet metal plate rolling machines and angle rolling machines.

FACCIN is the first plate bending roll supplier to use CNC on 4 roller plate rolling machines. In order to better meet the needs of every application, Faccin produces and sells various types of 3 or 4 roller metal sheet rolling machines.

3 models suitable for thin plates bending or rolling:

- HCU series: 2-roll plate rolling machine with high speed and productivity

- ASI series: initial pinch 3-roller bending rolls

- 3HEL series: 3-roll electronic pyramid plate bending machine with double pinch

2 models designed for thicker steel or other metal plates:

- 4HEL series: pyramid 4 roll electric roller machine

- HAV series: 3-roll variable geometry bending rolls

- Not everyone can afford the FACCIN rolling machine price.

- The cost performance is low for small and medium-sized enterprises.

- For ordinary users with limited capital, if the production scale is not large and the processing requirements are not high, there is no need to buy such a high-end rolling machine.

- FACCIN has the largest bending rolling machinery production factory in the world. With rich experience in production and sale of CNC plate rolling machine.

- Advanced and mature technology, able to roll all kinds of thin or thick plates. Provides the highest accuracy, productivity and long-term reliability.

- Sheet Metal Plate Bending & Rolling Automation is a strong product of Faccin. It can provide a wide range of automation functions.

- Through a wide network of agents and branches, it offers comprehensive sales and after-sales services worldwide.

- The technical level of FACCIN large-scale shipbuilding plate rolling machine is very high, which is the most worth purchasing. But the price is very high.

PROMAU DAVI is the largest plate rolling machine factory in Italy of heavy plate bending roll, angle steel rolling machine, high efficient production line and customized rolling mill. It is the leader in sales, employees, production, assets and grades with branches in Dallas (USA) and Shanghai (China).

Two types of 3-roll bending machine:

- MAV – variable geometry press rolling machine

- MCO – three roll double pinch rolling machine

Two types of 4-roll bending machine:

- MCA – four roll plate bending machine

- MCB – four roll plate bending machine

- The main product is heavy-duty rolling machine for extra thick sheet, not suitable for small or thin sheet metal.

- DAVI has the most patents in the industry. Due the longest history, the technical level is very high and reliable.

- Adopt the most advanced 3D CAD technology design. In order to ensure the strength and firmness of plate rolling machine, use finite element analysis method for testing.

- The entire network of more than 100 high-quality distributors ensures that they can provide sales and services at any time in any place.

- Provide dedicated customer support to meet customer needs. Highly specialized team can go to the customer’s workshop to provide onsite technical support or online help.

- Best sale three roller rolling machine is an ideal equipment for rolling thick steel plate.

- Suitable for users who need large-scale equipment and heavy-duty machines.

Kurimoto Co., Ltd. founded in 1909, is well-known sheet metal bending roll machine manufacturer in Japan. The science and technology of Japanese machinery manufacturing industry has been at the leading level in the world. Kurimoto high-precision sheet metal bending roller function brings precise cycle to the required applications.

- Japan Kurimoto upper roller universal type bending machine is the most well known.

- Widely used in pressure vessel, compression tank, heavy machine pats, ship parts, stainless steel tank, vehicle parts manufacturing and so on.

- Although it is an experienced plate bending machine manufacturer, KURIMOTO products of plate rolling machine for sale types are not rich and complete.

- The main products are only universal upper roller bending rolls.

- As the most famous Japanese roll bending machine manufacturer, Kurimoto plate rolling machine quality is trustworthy.

- High-rigid machine structure and high-precision sheet metal bending for high-end customers.

- Accurate circularity and cylindricality to reduce post-processing time.

- Energy saving and eco-friendly rolling machine for high standards of production factory.

The world’s top rolling machine manufacturer Switzerland HAEUSLER based on a long family tradition has a history of more than 80 years. It has large-scale specialized factories in Herten-Rheinfelden (Germany) and Duggingen (Switzerland).

- VRM 4-roll plate bending machine: used to roll aluminum, stainless steel or other metal tubes, tube segments, rounded boxes, ovals or other shapes.

- HDR 3-roll plate bending machine: vertical top roll and horizontal bottom roll movement offers more advantages than other 3 rollers bending machines in pre-bending or bending quality and work-piece handling.

- SPBM Ship plate bending machine: it can do press bending. The pressing tool can be mounted under the top roll.

Sheet metal or stainless steel plate rolling machine prices are higher than that of ordinary rollup rolling machines.

- The material and quality of the roller parts are very good. High alloy steel roller parts are very crack resistant.

- Also, provide second hand/used plate rolling machine service.

- HAEUSLER best sale four rollers bending rolls is very famous in the world. It is worth a try for users who need to buy 4-roll bending machines.

Founded in Sweden in 1964, ROUNDO has been developing rolling equipment for bending roll up plates and profiles. Now, the new headquarters is in the north of Italy.

There are 3 production base resources and more than 100 employees devoted to rolling bending machinery and technology. ROUNDO rolling machines represent unique quality, performance and reliability in the global market.

3-Roll

- PSE series: the most basic machine for plate thickness of 2 ~ 8 mm and width of 500 ~ 8000 mm.

- PS series: the most widely used machine for plate thickness of 1 ~ 100 mm and width of 500 ~ 8000 mm.

- PSS series: the most cost-effective bending roller for plate thickness of 1 ~ 160 mm and width of 500 ~ 8000 mm.

4-Roll

- PASS/PAS: 4-roll bending machine is an ideal choice for plates thickness of 1 ~ 25 mm and width of 500 ~ 8000.

- The price is very high, many users will choose second-hand/used Roundo machine.

- Although used ROUNDO machines are very attractive, it has a high price in the second-hand market.

- Engineers and technicians use the most advanced technology as well as the famous original experience and patented technology.

- Increased rotation speed: all ROUNDO rolling machines are equipped with infinitely variable speed.

- User friendly operation: Roundo has developed its own CNC system, which combines well-known standard components and software. They can best customize the control of plate rolling equipment.

- The excellent quality, performance, reliability and long service life of sheet metal bending rolls, as well as the continuous development and production process of high-quality machines, make customers satisfied.

Hugh Smith is an engineering and manufacturing company in the UK. It provides high quality engineering solutions for many industries, especially shipbuilding, pressure vessels and fabrication.

Hugh Smith rolling equipment mainly involves shipbuilding industry.

Shipyard Roll Press:

- From 600 tons to 3000 tons or more. Up to 21 meters in length

- DNC control system

- Deflection compensation of upper and lower beams

- Infinitely adjustable center of lower roll

Plate Level Rolling Machine:

- The frame structure has strength and rigidity

- Automatic control system

- Adapt to various board

There are few types of rolling equipment available to customers.

The area of expertise is limited to the shipbuilding industry.

- It is a division of Qualter, Hall and Co Ltd. with long history over 125 years.

- Have qualified and experienced engineering design, procurement, manufacturing and commissioning teams.

- Provide comprehensive turnkey project management services.

- Users who need a complete engineering solution can consult HUGH SMITH, especially in the shipbuilding industry.

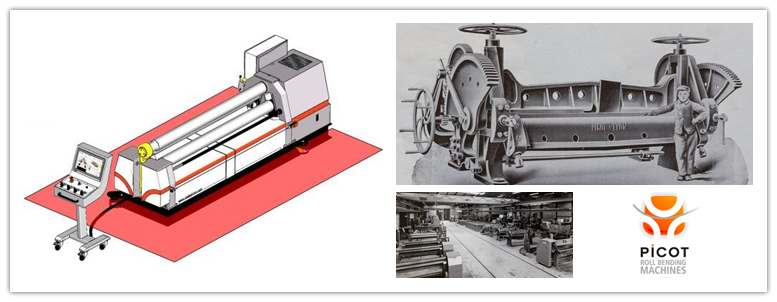

PIOCT is plate rolling machine manufacturer with the longest history in France. It has been working with customers for more than 150 years. “EASYROLL. NOW ROLLING IS A PIECE OF CAKE.” is the slogan. They try to make the rolling machine easy to understand and can be operated by everyone.

Three types of 3 Roll bending machine:

- RCE symmetrical 3-roll hydraulic bending roll and pre-bending machines: especially for the fine sheet.

- RCS symmetrical 3-roll hydraulic bending and pre-bending machines: power and quality. The most versatile and the most efficient.

- RAE electric mechanical asymmetrical 3 roll plate bending machines: simple and cheap.

4 Roll bending machine:

- R4C symmetrical 4-roll hydraulic bending and pre-bending machines.

Special rolling machine:

- Sheet metal tube profile bending machine.

- Vertical plate rolling machine: tailor-made bending machine adapt to your application and production environment.

- Limited product range. Compared with some manufacturers in Italy, there are few kinds of plate rolling machines.

- PIOCT French manufacturer has a very long history with over 150 years of experience in metal rolling and bending.

- The most significant highlight: easyroll

- They try to make the plate bending roll operation as simple as children playing games. Its purpose is to produce a rolling machine that everyone can use.

Fool-like operation and humanized design

- PIOCT plate rolling machines are easy to learn and convenient to control.

- If you are lacking in experience or do not have skilled manual operators, PIOCT plate bending roll machine is a good choice! Their goal is to make the bending roll ad a game that is simple enough for babies to complete.

You may also want to know