Traditional metal sheet cutting methods mainly include mechanical shearing, punching, flame cutting, plasma cutting, etc. These methods were widely used in early metal processing, but with the continuous improvement of processing accuracy, efficiency, flexibility and environmental protection requirements, their limitations and pain points are becoming increasingly apparent. The following is an analysis of the pain points of traditional metal sheet cutting methods.

Mechanical shearing: Suitable for straight-line cutting, the edges often have burrs and collapsed angles, and secondary grinding is required.

Punching by punching machine: The mold accuracy determines the product accuracy, but the mold is easy to wear, causing dimensional drift.

Flame/plasma cutting: The heat-affected zone is wide, the cutting edge is severely deformed by heat, and it cannot meet high-precision requirements.

Most traditional methods (such as shearing machines and punching machines) cannot process complex graphics or free curves, and can only cut regular graphics such as rectangles and circles.

Traditional stamping and shearing require mold replacement or readjustment of equipment, which is extremely unfriendly to small batch and multi-variety processing.

In today's world of diversified orders and customization, traditional cutting methods are difficult to respond to changes quickly.

One machine has one function, equipment resources cannot be reused, and single-piece processing time is long.

The process is not continuous, requiring manual handling, loading and unloading, and switching, which limits efficiency.

Flame cutting heats up slowly, and shearing/punching requires manual alignment and poor positioning accuracy, which affects continuous operation.

Equipment operation, mold adjustment, cutting path planning, etc. rely on experienced technicians, with a long training cycle and poor stability.

Flame cutting is accompanied by high-temperature open flames, which can easily cause fires; shearing machines are prone to pinching hands; punching press molds are highly dangerous.

Lack of automatic nesting function, material nesting mainly relies on manual experience, and material waste is serious.

Cutting deviation will cause scrapping or rework, further increasing material and labor costs.

Especially shearing and thermal cutting methods produce a large number of burrs and slag, requiring additional grinding equipment and man-hours.

During flame and plasma cutting, the high temperature causes the plate to warp, expand and contract due to heat, and it is difficult to ensure the quality of subsequent assembly.

Flame and plasma cutting require a lot of electricity or gas, which consumes a lot of energy and has high costs.

A lot of smoke, exhaust gas and high noise are generated, which puts pressure on the health of operators and environmental protection standards.

Punching machines and other equipment require frequent replacement and repair of molds, which has high maintenance costs.

For multi-variety and small-batch enterprises, the economic efficiency of traditional equipment has declined, and it is difficult to quickly recover the investment.

Pain point categories | Specific manifestations |

Precision issues | Rough incision, thermal deformation, many burrs |

Poor flexibility | High dependence on molds, slow changeover |

Low efficiency | Dispersed processes, much manual handling |

High reliance on manual labor | High technical threshold, high operating risk |

Serious material waste | Rough material arrangement, high rework rate |

Heavy post-processing burden | Many burr grinding and leveling processes |

High environmental pressure | Smoke and noise pollution, high energy consumption |

High maintenance and cost | Quick mold wear and high maintenance cost |

Traditional sheet metal cutting methods still have certain value in low-cost and single-volume production, but they are no longer able to meet the needs of today's industrial environment, which pursues high precision, high flexibility, fast delivery, and environmentally friendly manufacturing. Comprehensively upgrading to laser, CNC, and intelligent automated cutting technology is a key strategic path for sheet metal processing companies to improve quality and efficiency.

Comparison dimensions | Traditional sheet metal cutting methods (shearing machine/punch machine/flame/plasma) | Advanced cutting technology (laser cutting / CNC cutting / automated cutting) |

Applicable plate thickness | Medium and thin plates (shearing/punch machine) Medium and thick plates (flame/plasma) | Widely covers thin plates to medium and thick plates, 3mm-25mm is commonly used |

Processing accuracy | Large error (±0.5~1mm), obvious burrs, severe thermal deformation | High precision (±0.1~0.2mm), small kerf, small thermal impact |

Cutting profile | Limited to straight lines and regular graphics, special shapes are difficult to process | Any contour can be cut, supporting complex graphics and fine structures |

Flexibility | Requires mold change, long debugging time, slow response | Program control, fast switching drawings, high flexibility |

Efficiency performance | Suitable for large-scale repeated processing, small batch frequent changeover efficiency is low | Fast programming cutting, suitable for small batches of multiple varieties |

Post-processing requirements | Many burrs, need to be polished to remove slag, leveling, many processes | Smooth incision, basically no post-processing |

Easy nesting efficiency | Manual layout, high material waste | Intelligent typesetting, high material utilization (increased by 10%-20%) |

Labor dependence | High reliance on operating technology, high safety risks | Automated control, remote operation, good safety |

Environmental protection and energy consumption | High smoke, high noise, high energy consumption | Clean and environmentally friendly, low energy consumption, in line with green manufacturing standards |

Equipment cost | Low initial investment, high maintenance cost, high labor cost | High initial investment, but low operating costs, high overall return rate |

Traditional: Rough cutting edge, burrs or slag, especially flame cutting has a large thermal impact, which is easy to cause deformation.

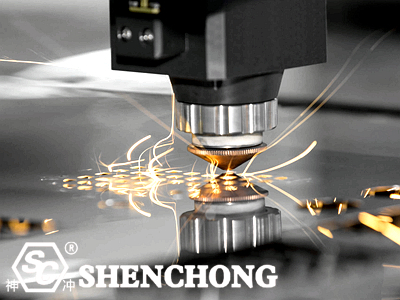

Advanced: Laser cutting has a small spot, narrow hot zone, smooth incision, almost no grinding, and directly enters the assembly process.

Traditional: Fixed mold or mechanical method, one graphic corresponds to a set of molds, slow changeover, and cumbersome debugging.

Advanced: Import drawings through CAD/CAM system, quickly program cutting, and flexibly respond to diversified orders.

Traditional: Plate nesting relies on experience, large gaps, and high scrap rate.

Advanced: Automatic nesting optimization software, which can be densely arranged, effectively reducing material waste.

Traditional: Most equipment is manually operated, with hidden dangers such as shearing, burns, and accidental injuries.

Advanced: Automatic feeding, remote monitoring, and fully closed processing greatly reduce the risk of human errors and safety accidents.

Traditional: Flame and plasma produce a lot of dust, smoke and high noise, and the working environment is poor.

Advanced: Laser cutting is a non-contact processing, environmentally friendly and clean, easy to manage the factory and meet ESG standards.

Industry | Current status of traditional methods | Advanced cutting methods transform value |

Sheet metal processing plant | Too many molds, slow changeover, delayed orders | Improve flexible production capacity to cope with small batches of multiple varieties |

Electrical box and cabinet manufacturing | Poor precision, incompatible installation | High-precision processing ensures assembly consistency |

Stainless steel decoration industry | Discoloration due to thermal cutting, edges need to be polished | Laser cutting does not change color and does not require polishing |

Construction machinery | Thick plates, severe deformation due to thermal cutting | Fiber laser/plasma CNC combined cutting is better |

Industry application | Recommended technical path |

Precision sheet metal processing | Laser cutting + automatic loading and unloading |

Decorative panels for furniture, kitchenware, etc. | Laser cutting + automatic bending |

Electrical control cabinets, electrical boxes | Laser cutting + intelligent nesting system |

Engineering structural parts | CNC plasma + laser composite cutting |

Large and thick plates/low-cost scenarios | CNC flame or plasma + semi-automatic auxiliary system |

Under the wave of Industry 4.0 and intelligent manufacturing, traditional metal sheet cutting methods can no longer meet the manufacturing needs of high quality, fast response, environmental protection and energy saving. Advanced technologies such as laser cutting, CNC cutting, and automated loading and unloading not only improve efficiency and quality, but also help companies stand out in fierce competition.