The sheet metal plate helps to automate the storage system and feed products to ensure production. It is important to have an intelligent storage system because you can use the laser cutting machine. It automatically loads and separates the finished products from waste. This way, you will have an easy time when you are storing your items.

The intelligent storage system is meant to aid with storage and also processing. With this system, you can easily separate finished products from waste. You can also feed products to a laser cutter and many more.

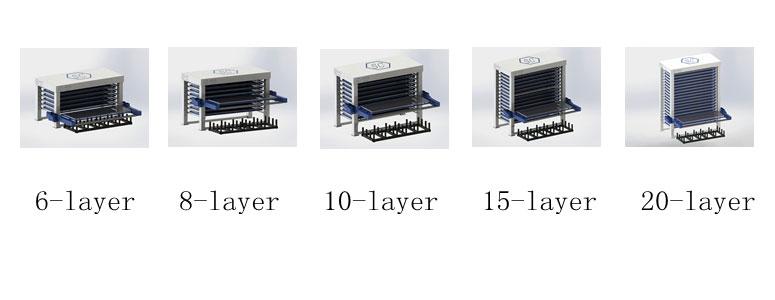

In short, you can look at this storage system as a way of managing raw materials and finished products. Here are different types of intelligent systems. These are used to store plates and they are controlled using a computer.

An intelligent sheet metal storage system is used to ensure that the metal plates can control the entry and exit of the plate. A computer helps to intelligently choose the plates and connects them using a system.

In warehouses, there are different types of automatic storage. They are ideal for different situations and they come in different shapes, lengths, thicknesses, and weights.

These are selected plates in a layer that automatically transports sheets when production is going on. They categorize as either single storage or multi-storage systems. The multi-storage systems are connected with a laser machine, robot automatic press, rolling center, and other production lines needed for production.

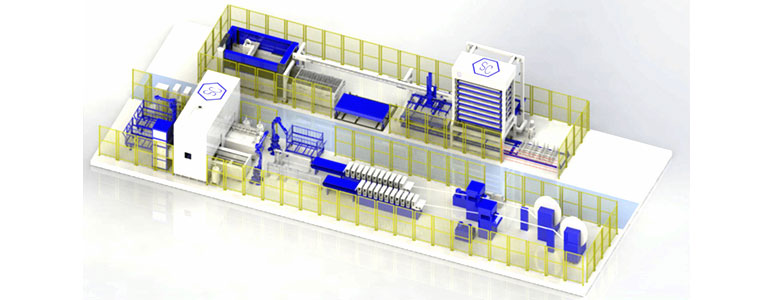

When you are using the intelligent storage system, you need to know that there are different components. These are the stages that a product will go through from raw material until it is a finished product.

The following are some of the components of an intelligent sheet metal storage system:

- Laser cutting machine

- A punching center

- A robot press brake

- Forming lines

- Rolling center

- Welding line

- Spray line

- Auto production line

These can be in any unnamed factory from raw material until it gets to the finishing line.

You may also want know What is a Flexible Manufacturing System (FMS)?

Because the intelligent system helps to make production easier, it has many advantages. You can easily store raw products, and the automated system will bring them to the finishing line and finished products.

The following are some of the advantages:

- The process is fast and intuitive

- It provides maximum efficiency and flexibility at the place of work

- Aid in protection and preservation of materials

- Saves storage space and time used to handle the materials

- It improves storage security and also operations

- The production management is clear and easier.

With the sheet metal storage system, you can easily store materials and save on space and time. The plates will make it easy for you to pick up heavy materials with ease. They can also help to store and you will cut the production time by a lot.

You can adjust the spacing between the shelves to fit the stored items. An optimization system will make it easy for you to minimize and develop a high detection space.