Stainless steel plate bending is a common process in sheet metal processing, and is widely used in kitchenware, equipment housings, medical equipment, decoration engineering and other fields.

Stainless steel plate bending is a common sheet metal forming process, but due to its special material properties, the bending process is more challenging than ordinary carbon steel. The following is a comprehensive analysis of stainless steel plate bending, including its material properties, process difficulties, equipment requirements, quality control and optimization suggestions.

- High strength and large rebound: Stainless steel has high hardness and large elastic modulus, and it is easy to rebound when bending.

- The surface is easily scratched: a protective film or protective pad is required to avoid direct contact between the mold and the plate.

- High requirements for angle control: The forming angle must be accurate to avoid angle deviation due to rebound.

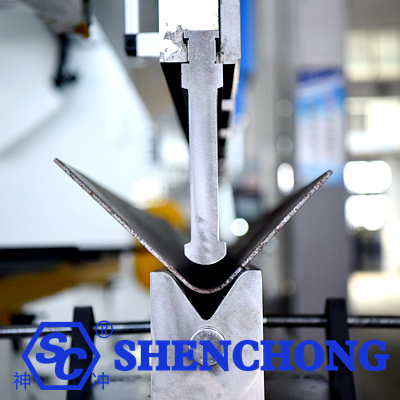

- High requirements for molds: high hardness molds are required, and special V-groove or knife-edge molds are required for some processing.

Bending stainless steel plates is more challenging than ordinary carbon steel or aluminum. Its difficulties are mainly reflected in the following aspects:

- Phenomenon: The angle is easy to rebound after bending, and the forming angle is too large.

- Cause: Stainless steel has a high yield strength and elastic modulus.

- Countermeasures:

Increase the bending angle (overbending) to compensate for the rebound.

Select a special mold or CNC machine suitable for stainless steel for angle compensation.

- Phenomenon: Microcracks or cracks appear on the bending edge.

- Cause: The bending radius is designed too small or the material hardness is too high.

- Countermeasures:

The inner R angle of the bend is not less than 1 times the thickness of the plate.

For high-strength stainless steel plates, appropriate annealing and softening treatment is performed.

- Phenomenon: The surface of the plate is crushed or scratched by the mold, affecting the appearance and corrosion resistance.

- Cause: The mold surface is rough or unprotected.

- Countermeasures:

Use film to protect materials.

Add rubber pads to the mold surface or choose molds that do not damage the material.

- Phenomenon: The mold life is short and the processing efficiency is low.

- Cause: Stainless steel has high hardness and poor wear resistance.

- Countermeasures:

Use high-hardness and wear-resistant mold materials.

Enhance lubrication and regularly maintain the mold.

- Phenomenon: Insufficient equipment tonnage and poor control accuracy lead to unstable bending quality.

- Cause: The pressure required for stainless steel bending is high and the precision requirements are high.

- Countermeasures:

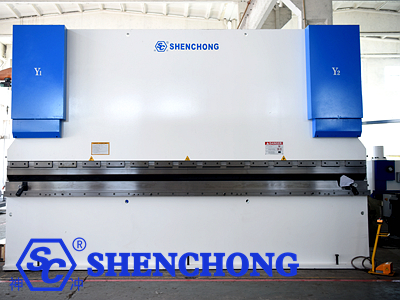

Use CNC electro-hydraulic synchronous press brake machine.

Reasonably match the plate thickness and machine tonnage.

Material thickness | Material | Common problems | Recommended bending radius | Required tonnage (per meter) |

1mm | SUS304 | Rebound, scratches | ≥1.0mm | 25~30 tons |

2mm | SUS304 | Cracks, inaccurate angles | ≥2.0mm | 50~60 tons |

3mm | SUS316 | Large rebound, cracked edges | ≥3.5mm | 80~100 tons |

- Reserve reasonable bending radius and tolerance in the design stage.

- Set accurate angle compensation in the process, and use multiple bending or slow bending.

- Equipment selection: Use high-precision CNC bending machines with angle feedback and compensation functions.

- Mold management: Use high-strength mold materials, and regularly inspect and replace them.

Stainless steel plate bending requires special attention due to its high material hardness, large rebound, and easy surface scratches. The following are the key points of stainless steel plate bending.

It is recommended to use CNC electro-hydraulic synchronous bending machine to facilitate angle compensation and multi-stage bending.

The equipment tonnage must be sufficient, and the bending tonnage is about 50% higher than that of carbon steel.

Stainless steel has a large springback and should be over-bent appropriately (exceeding the design angle by 2°~5°).

Use angle detection system or angle compensation function to improve accuracy.

The inner R angle of the bend is recommended to be ≥1 times the thickness of the plate to avoid cracking.

For cold-rolled stainless steel, R angle ≥1.5×plate thickness is safer.

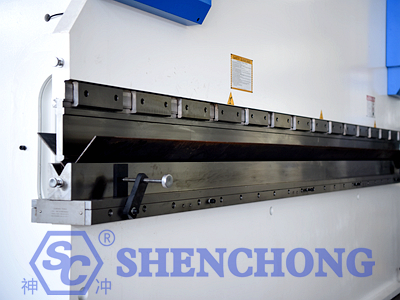

The width of the V groove of the lower mold is recommended to be 8~12 times the thickness of the plate.

Use arc or knife-edge molds for the upper mold to reduce indentation and cracking.

The mold surface must be flat and smooth, and soft rubber pads should be installed for protection if necessary.

The plate should be covered with a protective film.

Add rubber pads or paper pads to the mold contact surface.

Pay attention to cleaning before and after bending to avoid scratches from impurities.

During the bending process of stainless steel plates, special attention should be paid to the operation method, equipment selection and process parameters to avoid problems such as cracking, rebound, scratches, etc. The following are the key precautions for bending stainless steel plates.

Different grades (such as 201, 304, 316) have different strengths and ductility, and the bending parameters should be treated differently.

The thickness and surface state of the plate (mirror, brushed, lamination, etc.) also affect the bending quality.

A protective film should be applied before bending to prevent the mold from scratching the surface of the plate, especially the decorative plate.

The width of the lower mold V groove should be 8 to 12 times the thickness of the plate.

The mold surface should be smooth or equipped with a soft rubber pad to reduce indentation.

Stainless steel has a large elastic modulus and is easy to rebound during bending, requiring an overbending of 2°~5°.

It is recommended to use a CNC press brake machine with angle detection or compensation function.

The inner corner radius of the bend should be ≥ the plate thickness to avoid material cracking.

For thick plates or high-strength steel, it is recommended to use R-die bending to increase the bending radius.

Especially when bending along the rolling direction, cracks are more likely to occur.

It is recommended to stagger the bending direction or add annealing process (such as stress relief before bending).

According to the principle of short first, long second, inside first, outside second, complex first, simple second.

Multiple bends should avoid interference or deformation.

Use tools such as angle rulers and calipers to check whether the angle and size are within the tolerance range.

Check whether there are indentations, scratches, cracks, and deformations.

Pay special attention to the surface quality of mirror and brushed stainless steel.

Problems | Possible reasons | Solution |

Inaccurate bending angle | Rebound is not compensated | Increase compensation angle or use angle detection system |

Large bending angle | Rebound is not compensated | Increase bending angle or use angle compensation function |

Bending cracks | Bending radius is too small, direction is inappropriate or material is too hard | Increase bending radius, annealing and softening |

Surface scratches | No protective film or mold is rough | Use protective film, polishing mold or rubber pad |

Bending deformation | V groove is not suitable or edge height is insufficient | Select mold V groove reasonably and adjust edge height design |

- When the angle deviation is small, it can be adjusted appropriately by back pressure.

- It is recommended to test fold in small batches before mass production to confirm the process stability.

- For high-end products, it is recommended to use an automatic bending center to ensure consistency and accuracy.

- Before bending: confirm the thickness and material of the board, and apply a protective film;

- During bending: use a suitable mold to reasonably control the angle and R angle;

- After bending: check the angle, size, and appearance quality.

If you can provide specific data (such as plate thickness, material, length, bending angle, equipment model), I can calculate the specific bending force for you, recommend V-groove, mold or bending solution.