When selecting guillotine shear blades, it is necessary to comprehensively consider multiple aspects, including blade material, geometric parameters, matching machine tool model and working materials, gap and angle adjustment, and usage/maintenance costs. Below is a summary in two parts: "Key Points to Know" and "Recommended Process."

The selection of guillotine shearing machine blades is a crucial factor affecting shearing quality, machine lifespan, and production costs. Below is a systematic summary of the key selection considerations for guillotine shearing machine blades, covering five major aspects: material, structure, fit, precision, and cost.

Material Types | Features | Application |

9CrSi | High toughness, high cost-effectiveness, moderate wear resistance | Ordinary carbon steel, low alloy steel plates (≤6mm) |

6CrW2Si | Good hot hardness, high wear resistance | Medium and heavy plates, stainless steel plates (≤12mm) |

Cr12MoV / SKD11 | High hardness, high wear resistance, moderate impact resistance | Stainless steel, high-strength alloy plates |

H13 / 12CrMoV | Good thermal stability, strong impact resistance | Thick plates, high-strength steel, hot-rolled plates |

High-Speed Steel (HSS / SKH-9) | Extremely high wear resistance and hardness, highest cost | Special steel, high-strength high-frequency shearing operations |

Select guillotine shear blade material based on the material being cut (ordinary steel, stainless steel, alloy plate) and its thickness. For general stainless steel and high-strength plates, it is recommended to choose a grade of 6CrW2Si or higher.

- Perfectly matches the machine tool's shearing length (e.g., 2500mm, 3200mm, 4000mm, etc.).

- Thickness, width, hole spacing, and positioning grooves should be strictly machined according to the original machine tool standards.

- Custom blade dimensions are available for non-standard models.

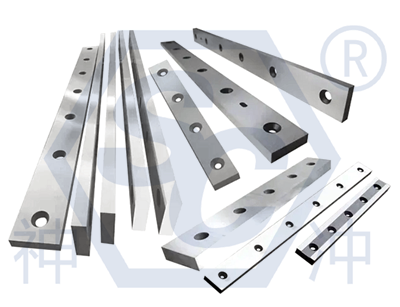

- Straight-edge type: Suitable for general steel plate shearing.

- Angled-edge type: Reduces shearing force and plate deformation (commonly used in guillotine shearing machines).

- Reversible blade type: Multi-blade design (e.g., 2 or 4 blades), can be flipped multiple times for reuse, reducing costs.

- Confirm that the blade model matches the structure and fixing method of the guillotine shear blade holder (e.g., bolt hole positions, installation angle).

- Blade angles, mounting hole positions, and cutting edge shapes are not interchangeable between different machine models (guillotine vs. swing arm shearing).

- The thicker or harder the sheet material being sheared, the higher the grade of the blade material should be, and the shearing angle and clearance should be appropriately increased.

- Typically HRC 56~60 (9CrSi)

- High-grade materials can reach HRC 58~62

- The hardness of the upper and lower blades should match to avoid uneven wear.

- Flatness error ≤ 0.03 mm/m

- Parallelism error ≤ 0.02 mm

- Accuracy directly affects shearing quality and blade wear uniformity.

- Common angles for guillotine shears: 0.5°~2.5°

- Clearance is generally 5%~10% of the thickness of the plate being sheared, adjusted according to the material hardness.

- A reasonable clearance can reduce burrs and plate deformation.

- Sharpening Times: High-quality blades can be repeatedly sharpened 5–10 times or more.

- Heat Treatment Process: Vacuum quenching + low-temperature tempering can improve toughness and stability.

- Accessories and After-Sales Service: Choose reputable manufacturers with material testing reports and heat treatment reports. Economic efficiency: Although blades with longer lifespans are more expensive, their long-term operating costs are lower.

Below is a relatively systematic process for your reference when selecting blades:

Sheet metal:

- Material (low carbon steel/hot-rolled steel/stainless steel/alloy plate)

- Thickness range (e.g., 1 mm, 5 mm, 10 mm, 20 mm…)

- Length/Width (machine throat depth, shearing area)

Precision requirements (whether burrs are allowed on the plate edge, the amount of deformation, whether zero deformation is required)

Processing frequency/output (high-frequency cutting vs. occasional use)

Confirm that your guillotine shearing machine (model, shearing length, blade installation dimensions, stroke) matches the blade specifications.

Request a recommended blade material and specification table from the machine tool supplier or blade supplier.

Select the appropriate material based on the plate material and thickness. For example: 9CrSi is generally suitable for low carbon steel plates. 6CrW2Si or better is recommended for stainless steel or high-strength plates.

Check if data on heat treatment, edge hardness, and wear resistance are available.

Determine the blade length, thickness, cutting edge width, and whether it can be flipped (some blades have multiple cutting edges for interchangeable facets).

Is it a standard specification or requires customization? Can the supplier process it according to the drawings?

Determine if the hydraulic cylinder/tool holder/guide rail matches the blade structure.

Confirm whether the machine tool itself has blade clearance and shearing angle adjustment functions (automatic or manual). Even with good blades, if the clearance or angle is incorrect, the shearing quality will be poor.

Communicate with the blade supplier regarding recommended clearance values and usage experience.

Confirm whether the blade supplier maintains regular inventory, can supply quickly, and provides repair/blade flipping services.

Can they provide technical support, blade replacement advice, and durability data?

Consider initial cost vs. lifespan estimation: If the blade life is short, the long-term cost may be higher.

Before installation, confirm that the blade edge is undamaged, the heat treatment is normal, and the material markings are complete.

After installation, adjust the gap and angle, and perform an initial test cut to confirm that the edges, deformation, and burrs meet the requirements.

During use, regularly check the blade wear, whether the edge is chipped, and whether it needs sharpening or replacement.

Do not cut materials exceeding the tolerance of the insert material/machine tool; otherwise, insert life will decrease drastically.

If the sheet metal contains hard impurities (such as weld slag, spark slag, or deposits), it will accelerate insert wear. Cleaning the sheet metal is recommended.

Once the insert becomes dull or the cutting edge is chipped, it should be replaced or re-ed promptly. Otherwise, it will affect the cutting quality (deformation, burrs, warping) and may damage the machine tool.

Keep the inserts, machine tool guideways, hydraulic cylinders, and guide structures clean and well-lubricated, as good mechanical condition helps extend insert life.

For cutting special materials (such as extra-thick steel, stainless steel, wear-resistant plates, and high-strength plates), it is recommended to use a higher-specification insert material, even if the initial cost is higher. In the long run, it is more economical.

① Clarify the intended use: Type of sheet metal, thickness, output, and precision requirements.

② Compare with machine model: Match blade size, hole spacing, and installation angle to the machine tool.

③ Select material: Choose materials such as 9CrSi, 6CrW2Si, and Cr12MoV based on sheet metal hardness.

④ Check precision: Flatness, hardness, and heat treatment report.

⑤ Consider service: Does the manufacturer provide installation and sharpening services?

⑥ Overall cost: Evaluate the initial price + service life + maintenance cycle.