Intelligent sheet metal manufacturing refers to the application of intelligent technologies to sheet metal processing. Through automated equipment, digital control, the Internet of Things, artificial intelligence, and other technologies, it enables efficient, precise, and flexible production of sheet metal products.

With the rapid development of the industry, smart sheet metal manufacturing has become crucial for improving production efficiency, reducing costs, and optimizing quality. However, during its implementation, misconceptions about smart sheet metal manufacturing still exist. Below are some common misconceptions and their corresponding correctives.

Many people believe that intelligent sheet metal manufacturing simply refers to automating traditional sheet metal processing processes, replacing manual operations with automated machinery, such as automated stamping, laser cutting, and bending.

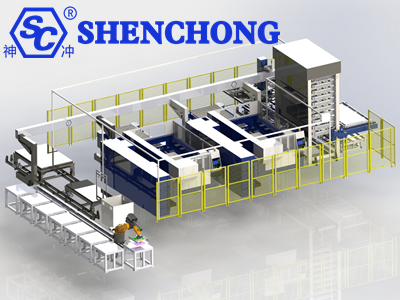

Sheet metal intelligent processing is more than just automated processing. It also encompasses comprehensive digital management, refined process control, production process optimization, and intelligent decision support. It involves intelligent management of the entire life cycle, from design, production, logistics, quality inspection, to after-sales service.

The core of intelligent manufacturing lies in achieving intelligent, flexible, and optimized production processes through data collection and analysis, the Internet of Things, cloud computing, big data, and artificial intelligence.

Many people mistakenly believe that intelligent sheet metal processing is completely "fully automated" production, meaning that once the system is set up, the production process requires no human intervention.

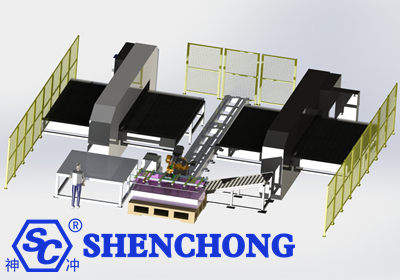

Although intelligent manufacturing can significantly improve production efficiency, it is not "fully automated." In actual applications, intelligent manufacturing emphasizes "human-machine collaboration." During the production process, human labor is still required for system debugging, equipment maintenance, quality inspection, and exception handling.

Smart sheet metal processing aims to improve productivity through automation and intelligence, but it cannot completely replace manual labor. Human labor still plays an irreplaceable role, particularly in complex process adjustments, equipment maintenance, and technological innovation.

Some believe that intelligent sheet metal processing technology is suitable for all businesses, especially small and medium-sized enterprises (SMEs), believing that simply introducing advanced smart equipment and systems will enable business transformation.

While sheet metal intelligent manufacturing offers numerous benefits for most businesses, not all will benefit immediately. Smart manufacturing investments often require high initial costs and technical support.

When implementing smart manufacturing, SMEs need to consider their own production capacity, technical expertise, financial resources, and market demand. For SMEs, a gradual, phased implementation strategy is recommended, selecting appropriate technologies and equipment and avoiding blindly following trends. In practice, sheet metal smart manufacturing solutions should be tailored to the specific circumstances of the business.

Some believe that the core of smart sheet metal processing lies in advanced production equipment, and that other hardware and software infrastructure, such as information systems and data acquisition systems, can be ignored.

Intelligent sheet metal manufacturing requires not only advanced equipment but also efficient information systems. Information systems and data acquisition technologies can help companies obtain real-time production data, monitor anomalies in the production process, and implement fault warnings, maintenance management, and production scheduling.

Through big data analysis and cloud computing platforms, companies can optimize production processes, improve efficiency, and accurately predict demand. Information systems are the foundation for comprehensive smart manufacturing. Only when equipment and information systems are combined can truly intelligent production be achieved.

Many companies and managers believe that the introduction of smart sheet metal manufacturing will yield significant results quickly and have a very short payback period.

Intelligent sheet metal processing is a long-term investment process, not a short-term one. The effects of smart manufacturing often take time to manifest, especially in areas such as data collection, production process optimization, and employee skills development.

When introducing intelligent manufacturing, companies should clarify their expectations, develop long-term strategic plans, gradually integrate and optimize systems, and prioritize technological advancements and talent development. While the payback period may be long, in the long run, it can lead to higher production efficiency, lower costs, and improved quality control.

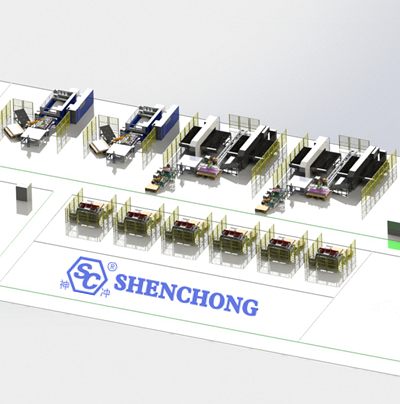

Smart manufacturing involves more than just introducing advanced equipment; it is a comprehensive systems engineering effort encompassing processes, equipment, information systems, data analysis, artificial intelligence, and other aspects.

Successful intelligent sheet metal processing requires the coordination and integration of all aspects, including the digitization, informatization, and networking of the production process, as well as optimized decision support systems.

The prerequisite for achieving maximum efficiency in smart sheet metal manufacturing is to establish a comprehensive data collection and analysis mechanism. Using technologies such as sensors, machine vision, and the Internet of Things, real-time production data is captured, and optimized decisions are made through big data analysis and artificial intelligence algorithms. Data-driven decision support systems can enhance production flexibility and accuracy, reduce resource waste, and improve overall production efficiency.

Smart sheet metal manufacturing enables flexible production to meet diverse batch, small-batch, and diversified customization needs. Through intelligent sheet metal production line scheduling and process optimization, it can quickly adapt to market changes and meet personalized customer needs, rather than simply relying on large-scale, standardized production.

Smart manufacturing emphasizes human-machine collaboration, not simply replacing human labor with machines. The intelligent, automated, and flexible nature of equipment can significantly improve production efficiency, but the decision-making capabilities, flexibility, and adaptability of artificial intelligence and robots remain limited. Therefore, the close integration of human decision-making, technological innovation, and intelligent machine operation is the core of smart manufacturing.

Intelligent sheet metal processing is more than just introducing advanced automated equipment and technology. It is a systematic innovation process involving the deep integration of technology, management, and culture.

In practical applications, companies need to understand their own needs, formulate scientific plans, and gradually advance the transformation to smart manufacturing. Avoiding one-sided understanding and blindly following trends, and focusing on the organic integration of technology and human resources, companies can stand out in the fiercely competitive market.