The Metal Profile Intelligent Storage System is a highly efficient warehousing solution integrating automated storage, information management, and intelligent scheduling. This system primarily addresses the storage needs of long, rectangular materials such as aluminum profiles, steel profiles, stainless steel pipes, and copper rods. By integrating three-dimensional racks, automated stackers, conveying equipment, and the WMS/WCS intelligent control system, it enables automated warehousing, outbound delivery, inventory, and traceability, effectively improving warehousing efficiency, reducing labor costs, and ensuring safety.

The Shenchong intelligent storage system for metal profiles consists of the following five main components:

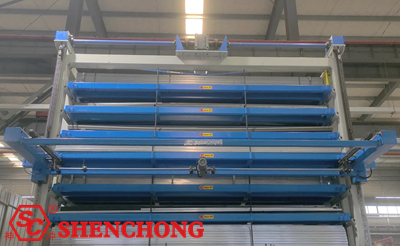

- Adopts a cantilever or drawer-type structure, suitable for materials 6–12 meters long.

- Material: High-quality Q235 steel, surface electrostatically sprayed for rust prevention.

- Designed to resist lateral forces and collisions, with customizable shelf heights and load capacities.

- Maximum load per shelf: 500kg–2000kg (optional).

- Stacker/Elevator: Servo-controlled, positioning accuracy ±2mm.

- Gripping Mechanism: Adapts to various profile specifications, automatically gripping and placing.

- Operating Speed: 60–120m/min horizontally, 30–60m/min vertically.

- Control Method: PLC + servo closed-loop control system.

- Roller/Chain Conveyor: Connects to the stacker and processing line.

- Automatic steering mechanism: Enables multi-directional transport and diversion.

- AGV/RGV transporters (optional): Enable intelligent cross-regional dispatching.

- Implements inventory data management, task allocation, and barcode/RFID recognition.

- Supports batch management and first-in-first-out (FIFO) logic.

- Provides real-time inventory status, statistical reports, and inbound and outbound records.

- Can seamlessly integrate with MES and ERP systems.

- Responsible for equipment-level control and dispatch, and real-time communication with the WMS.

- Utilizes industrial Ethernet communication (TCP/IP, PROFINET, etc.).

- Provides a visual operation interface and alarm notification system.

The system automatically identifies material information by scanning barcodes/RFID tags, assigning optimal storage locations and ensuring accurate inbound delivery.

Automatically selects and dispatches materials to designated processing stations based on production instructions or ERP scheduling tasks.

Real-time display of inventory quantity, specifications, location, batch, and other information.

Supports inventory counting, alarm notifications, and report export.

Trace the entire material flow from inbound, storage, to outbound delivery.

Provides a 3D warehouse monitoring interface that dynamically displays storage location status and equipment operation status.

Interconnects with equipment such as laser cutting machines, sawing machines, and CNC machining centers to achieve intelligent loading and unloading.

- Multi-level limit protection: Triple protection including travel limit, coded limit, and software limit.

- Collision and fall prevention devices: Ensure safe operation of the stacker crane and pallet.

- Emergency stop system: Equipped with an emergency stop button and fault alarm.

- Electrical safety protection: Complies with CE safety standards.

- Fire protection and temperature and humidity monitoring (optional): Provides real-time environmental monitoring and alarms.

The intelligent metal profile storage system combines automated equipment with an information management platform to achieve efficient, precise, and safe management of long metal materials (such as aluminum profiles, steel pipes, H-beams, stainless steel square tubes, copper rods, etc.). Compared to traditional manual storage methods, it offers significant advantages in terms of efficiency, space, safety, information technology, and intelligent management.

Automated inbound and outbound storage improves efficiency by over 200%.

The system automatically identifies material information and schedules optimal routing, reducing inbound and outbound storage times to just 30–60 seconds.

Seamless Integration with Production Lines

Directly connects to sawing machines, laser cutting machines, CNC machining centers, and other equipment, achieving an integrated "warehousing-production" flow.

Reduced Manual Operation Time

Automated stackers, conveyor lines, and AGVs replace manual handling, significantly shortening material retrieval time.

The three-dimensional design reduces floor space by 30–50%.

Fully utilizes vertical space, increasing storage capacity per unit area by over 50%.

Flexible Storage Space Planning

Dynamically allocates storage spaces based on profile length, specifications, and weight, achieving high-density storage.

Scalable Structure

Modular design supports future expansion of floor heights or storage spaces to meet production capacity growth needs.

WMS Warehouse Management System

Real-time recording of material inbound and outbound information, inventory, batches, and locations.

Supports barcode/RFID scanning for precise traceability.

WCS Equipment Control System

Intelligently dispatches stacker cranes and conveyor systems for automated task execution.

Supports remote monitoring, fault alarms, and automatic route optimization.

Strong System Integration Capabilities

Seamlessly integrates with enterprise information systems such as ERP, MES, and APS for integrated production data management.

Automatic Anti-Collision and Limit Protection

Multiple safety controls (soft limit, photoelectric detection, and mechanical limit) ensure safe equipment operation.

Reduced manual handling risks

Fully automated processes prevent profile drops, scratches, and crushing.

High structural strength and earthquake-resistant design

High-strength three-dimensional racking and secure locking structure meet heavy-duty industrial load requirements.

Full batch and material traceability

Integrated records from incoming to outgoing warehouses ensure clear material origins.

Automated Inventory and Statistical Analysis

The system generates real-time inventory reports, enhancing warehouse transparency.

Visual Interface Operation

The 3D warehouse model displays equipment and location status in real time, making it intuitive and easy to use.

Reduce labor costs by 40–60%.

Reduce the number of forklift drivers, warehouse staff, and movers.

Reduce material loss and errors

Automatic identification and precise handling by the system effectively reduce the risk of profile scratches and misplaced materials.

Short Return on Investment

The investment cost is generally recovered within 1.5–2 years (depending on the company's scale and frequency of use).

Modular system structure

Supports future expansion, structural upgrades, or the addition of AGV/RGV systems.

Compatible with a wide variety of materials

Automatically identifies and stores materials based on length, weight, and cross-sectional dimensions.

Continuously Optimizable Software

Supports secondary development, data access, and cloud management.

Reduced energy consumption and carbon emissions

Optimized stacking paths and reduced inefficient operations.

Paperless Management

All operations are completed via electronic instructions, supporting mobile terminal operation.

Compliant with Smart Factory and Industry 4.0 standards

Achieves a closed-loop management system of "warehouse automation + data connectivity + intelligent decision-making."

Project | Traditional | Intelligent |

Land Area | Large | Reduces by 30-50% |

Operating Efficiency | Relying on manual labor | Increases by over 200% |

Management Method | Manual record keeping | Automated informationization |

Material Loss | High | Significantly reduces |

Safety | Risk of manual handling | Automated handling is safer |

Traceability | Unable to accurately track | Full process traceability |

Due to its high efficiency, high density, traceability, and safety and reliability, the metal profile intelligent storage system is suitable for a variety of industries primarily storing long, rectangular materials (such as aluminum profiles, steel pipes, copper rods, and stainless steel profiles). The following is a classification and detailed description of its main application industries.

Application Scenarios:

Aluminum profile extrusion lines, oxidation workshops, and deep processing workshops.

System Value:

- Fully automated flow from extrusion → cooling → sorting → storage → processing.

- Precisely manages aluminum profiles of varying batches and specifications.

- Reduces manual handling damage and improves outbound delivery efficiency.

Typical Enterprises:

Door and window profile factories, industrial aluminum profile factories, and photovoltaic aluminum frame manufacturers.

Application Scenarios:

Storage of profiles such as H-beams, square tubes, round tubes, angle steel, and flat steel.

System Value:

- Automatically identifies material size, weight, and storage location. Integration with cutting machines, drilling machines, and welding lines enables intelligent distribution.

- Effectively reduces workshop floor space and improves steel component turnover efficiency.

Typical enterprises:

Building steel structure factories, heavy equipment factories, and bridge manufacturers.

Application Scenario:

Warehousing and distribution of aluminum alloy doors, windows, curtain wall components, and decorative profiles.

System Value:

- Intelligent zoning prevents mixing of profiles of different colors or models.

- Automated outbound delivery, coordinated with the unloading center, enables unmanned distribution.

- Reduced handling time and the risk of profile scratches.

Application Scenario:

Warehousing of raw materials and semi-finished products in bending, cutting, and welding workshops.

System Value:

- Automatically manages the flow of raw materials and semi-finished products.

- Interface with the MES system to synchronize "production-warehouse" information.

- Optimizes material distribution routes and reduces waiting and idle time.

Application Scenario:

Production lines for solar racks, energy storage boxes, wind turbine tower supports, and more.

System Value:

- Enables centralized storage and rapid access to various long metal parts.

- Ensures material batch traceability and meets export product quality system requirements.

Application Scenario:

Body frame profiles, aluminum alloy track components, chassis beams, guide rails, and more.

System Value:

- Intelligently manages various vehicle body profiles and supports automated sorting.

- Cooperates with AGVs/robots to achieve automated loading and unloading.

- Improve production consistency and logistics coordination efficiency.

Application Scenario:

Mechanical structural parts, automation equipment frames, and industrial aluminum profile warehousing.

System Value:

- Enables modular warehousing and supports small-batch management of multiple varieties.

- Improve material preparation efficiency and production response speed.

Application Scenario:

Copper rods, stainless steel profiles, brass tubes, wire rods, and more.

System Value:

RFID identification enables precise material and batch tracking.

Prevents material oxidation and scratches, improving warehouse safety.

Industry Types | Main Materials | System Application Value |

Aluminum Profile Manufacturing | Aluminum profiles, aluminum bars | Fully automated management improves warehousing and outbound efficiency |

Steel Structure Manufacturing | H-beams, square tubes | High-density storage and automatic sorting |

Doors, Windows, and Curtain Walls | Door and window frames, columns | Prevents material mix-ups and scratches with intelligent warehousing and outbound delivery |

Sheet Metal Fabrication | Sheets, support profiles | Interfaces with production lines for real-time delivery |

New Energy Equipment | Photovoltaic racks, energy storage enclosures | Accurate traceability and quality control |

Automotive/Rail Transit | Aluminum alloy beams, guide rails | Intelligent scheduling and paced production |

Machinery Manufacturing | Industrial aluminum profiles | Quick material preparation and reduced labor |

Non-ferrous Metal Processing | Copper rods, stainless steel tubes | Batch management and corrosion protection |