- Laser Injury: High laser energy; direct viewing or accidental entry into the cutting area can easily burn the eyes and skin.

- Fire Risk: Numerous cutting sparks, residue from the sheet metal, oil, or paper scraps can easily ignite a fire.

- Hazardous Fumes: The fumes and gases produced during cutting are harmful to health if inhaled; the risk is greater in poor ventilation.

- Electric Shock Hazard: High voltage; aging wiring or improper maintenance can easily lead to electric shock.

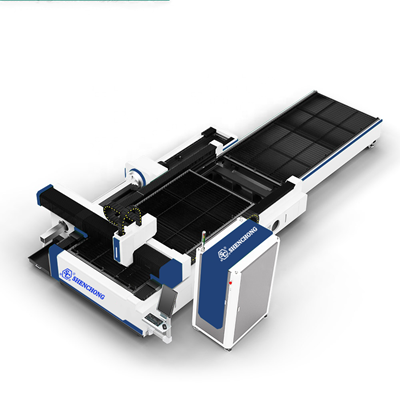

- Mechanical Injuries: The crossbeam, exchange table, and grippers move rapidly, easily causing hand injuries or collisions.

- Gas Risks: High pressure oxygen and nitrogen gases; leaks or misuse can lead to deflagration.

Below is a practical safety guide for laser cutting machines, applicable to sheet metal laser cutting machines (especially fiber lasers).

The core of the laser cutting machine is the laser, which can produce a high-intensity, monochromatic and highly directional laser beam. Common types of lasers include CO2 lasers, fiber lasers, YAG (Nd:YAG) lasers, etc. Different types of lasers are suitable for different materials and applications.

The laser beam generated by the laser is transmitted to the cutting head through a reflector or optical fiber, and the focusing lens focuses the laser beam into a very small point (focus). At this focus, the energy density of the laser beam is very high, enough to quickly heat the material to the temperature of melting or even vaporization.

When the focused laser beam is irradiated on the surface of a material, the material absorbs the laser energy and heats up rapidly. For most metals and other materials with good thermal conductivity, the laser energy is concentrated in a very small area, causing the local temperature to rise sharply, causing the material to melt or directly vaporize. This process occurs very quickly, usually only a few milliseconds or even shorter.

During the laser cutting process, auxiliary gases (such as oxygen, nitrogen or compressed air) are often used. These gases are ejected from the nozzle and blown coaxially with the laser beam toward the cutting area.

For non-metallic materials or applications where an oxidized edge is not required, an inert gas (such as nitrogen) is generally used to remove the melt and cool the cut surface to obtain a clean, oxidation-free cut.

For metal materials, especially low carbon steel, active gases (such as oxygen) can be used as combustion aids to promote the combustion reaction, increase the cutting speed and reduce the required laser power.

- Laser generator produces laser beam. Brief description:

The laser generator in the laser cutting machine produces a high-energy, high-concentration laser beam. Commonly used laser types include CO2 laser, fiber laser and solid laser.

- Laser Beam Steering and Focusing Briefly:

Laser beams are directed and focused into a small diameter spot by means of optics such as lenses or mirrors. These optics are often used to control the path of the laser beam and focus it into a smaller spot.

- A brief description of material absorption of laser energy:

When the laser beam hits the surface of a material, the material absorbs the energy of the laser. The absorption rate varies between different materials, and some metal materials have a higher absorption rate of lasers.

- Heating, melting or vaporizing materials:

The high energy density of the laser heats the material quickly to the melting or vaporization temperature. The melting or vaporization of the material consumes a lot of heat energy to achieve cutting.

- A brief description of auxiliary gas injection:

During the cutting process, auxiliary gas (such as nitrogen, oxygen or inert gas) is often sprayed through the nozzle to protect the laser cutting area, blow away the melted material and help speed up the cutting speed. Different auxiliary gases have different effects on the cutting quality.

For example, when oxygen is used as an auxiliary gas, while blowing away the molten metal liquid, an oxidation reaction will also occur to promote the endothermic melting of the metal, thereby achieving the melting of thicker materials, but it will cause obvious oxidation of the cut surface of the material, and produce a quenching effect on the material around the cut surface. When nitrogen is used as an auxiliary gas, a protective atmosphere will be formed around the molten metal liquid to prevent the material from being oxidized, thereby ensuring the quality of the cut surface, but the nitrogen consumption is very large, resulting in an increase in cutting costs; when air is used as an auxiliary gas, the cost is very low, and its cutting effect is between nitrogen cutting and oxygen cutting. For carbon steel plates, the cut section will produce smaller burrs, for stainless steel plates, the cut section will produce a yellow oxide layer, and for aluminum plates and aluminum alloy plates, the cutting burrs will be reduced relative to nitrogen.

- Motion control system brief description:

Laser cutting machines are usually equipped with a motion control system to control the motion path of the laser cutting head on the material surface. This can achieve cutting of various complex shapes, controlled by a computer program.

High precision Brief description: The cutting edge is smooth and no secondary processing required

The laser cutting machine uses a high-energy-density laser beam for cutting. Due to the good focusing and concentrated energy of the laser beam, it can achieve a very small incision width when cutting materials, making the cutting edge very smooth. Compared with traditional cutting methods, no secondary processing is required, which greatly improves production efficiency and product quality.

Fast speed Brief description: High production efficiency

The cutting speed of the laser cutting machine is very fast. Laser cutting speed is around 300% higher than that of plasma. And during the cutting process, there is no need to perform complicated fixture installation and disassembly like traditional cutting methods, which saves the auxiliary time of loading and unloading materials and greatly improves production efficiency.

A wide range of cuttable materials Brief description

Including various materials such as metal, plastic, glass, etc. At present, there are many types of laser cutting machines, and different types of laser cutting machines have different adaptability to materials. For example, CO2 laser cutting machines are suitable for cutting non-metallic materials such as plastics, rubber, wood, paper products, leather, and natural or synthetic organic materials; fiber laser cutting machines and YAG solid-state laser cutting machines are mainly used for cutting metal materials. In addition, laser cutting machines can also cut composite materials such as carbon fiber and glass fiber reinforced plastics.

No need for cutting tools. Brief description: Reduce tool wear and replacement costs

Traditional cutting methods require the use of cutting tools, which will continue to wear during use and need to be replaced regularly, which not only increases production costs but also affects production efficiency. Laser cutting machines do not require cutting tools. They use high-energy-density laser beams to heat the material to above the sublimation point or melting point to achieve cutting, reducing tool wear and replacement costs.

The equipment cost of laser cutting machine is relatively high, especially high-power laser cutting machine, which is expensive. In addition, the maintenance cost of laser cutting machine is also high, and key components such as laser and optical devices need regular maintenance and replacement, which also increases the cost of use.

Professional operators are required for operation and maintenance. Laser cutting machine is a high-precision and high-speed equipment that requires professional operators for operation and maintenance. Operators need to have certain professional knowledge and skills and be familiar with the operation process and maintenance methods of the equipment, otherwise it is easy to cause equipment failure and safety accidents.

Heat and harmful gases will be generated during the cutting process. Laser cutting machine will generate heat and harmful gases such as carbon dioxide, carbon monoxide, nitrogen oxides, etc. during the cutting process. These harmful gases have certain hazards to the environment and human health, and corresponding environmental protection measures need to be taken to deal with them.

The heat generated during the cutting process may affect the cutting quality. Laser cutting machines generate a lot of heat during the cutting process, which may cause material deformation, discoloration, oxidation and other problems, thus affecting the cutting quality. In order to reduce the impact of heat on cutting quality, corresponding cooling measures need to be taken, such as using auxiliary gas for cooling.

Here's a clear, practical overview of laser cutting machine safety, suitable for operators, supervisors, or workshop posters.

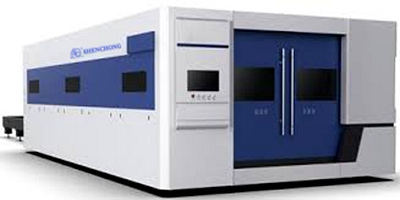

Laser cutting machines are the most powerful laser equipment in the industrial field. With the advancement of current industrial design, most of the cutting laser processing machines we see now are basically fully enclosed. Even if professional personnel operate them, they cannot be exposed to dangerous lasers.

Because the power is too high, it is normal to have several kilowatts or tens of thousands of watts, or even 20,000 or 30,000 watts, in order to process large-sized materials.

Pay attention to the product, try to add laser attenuation measures, and then add a protective cover for the overall structural design, at least one observation window, so that the laser does not directly hit the human eye, or the laser reflection does not reach the human eye directly.

It is best to do a chain design, that is, as long as the door is opened, we want to add materials, or we want to replace related parts, we must stop the laser emission immediately in the chain state. That is, the chain can be made into this kind of chain protection.

At the same time, the equipment must also have warning measures for radiation emission, or warning devices, as well as entry keys, plus manual keys, and match multiple links to control the opening.

Whenever the laser power supply is disconnected or the interlock is started, it must be restarted, and measures and steps for restarting must be added. It cannot be fired directly. Try to make the restart action complicated so that the personnel cannot simply fire the laser.

The manual must contain complete laser parameters and parameters of the accessible area, so that it can be guaranteed whether the professionals need to wear protective gear and the specifications of wearing protective gear. Some better guidance and instructions are provided in the manual.

Laser labels, for this type of equipment, we should try to add laser warning labels on each removable or openable door. That is, after opening the door, you may be exposed to a certain level or power of laser equipment, and make clear reminders before opening each door, so that the operators can be as safe as possible during the operation.

The overall principle is to attenuate and protect the laser as much as possible. Try to let the operator go through multiple steps before the high-power laser can be directly fired.

The manual should make clear measures for the specifications of the laser, the protection requirements, and the guidance of our operators. However, if there is no complete protection interlock design, we must clarify the external interlock measures and designs in the manual.

With the continuous expansion of domestic and foreign markets, laser cutting machine companies will usher in more development opportunities. Companies can improve product quality and performance to meet the needs of different customers by strengthening technological innovation and product research and development. At the same time, they can enhance the company's visibility and reputation and expand domestic and foreign market share by strengthening marketing and brand building.

Laser cutting machines are high-energy and high-speed, and their main risks include laser burns, fires, smoke and dust hazards, electric shocks, mechanical injuries, and high-pressure gas risks. However, by ensuring adequate personnel training, complete protective equipment, activated ventilation and dust suppression systems, unattended operation, and immediate shutdown upon detecting any abnormalities, the incidence of safety accidents can be effectively reduced.

A laser cutting machine safety reminder in one sentence:

"Do not look directly at the machine, do not approach it, do not leave your post, ventilate the area first, and stop the machine immediately if any abnormality is detected."

Related information:

Laser Cutting Machine Price Analysis

Fiber Laser Cutting Machine Maintenance Guide

Laser Cutting Parameters Detailed Explanation [What, Why, How]

Laser Cutting Repeat Positioning Accuracy Improvement Solution And Technical Analysis

Fiber Laser Cutting Machine Market Analysis