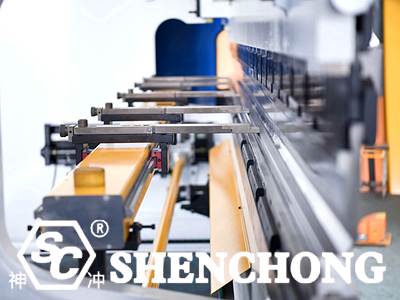

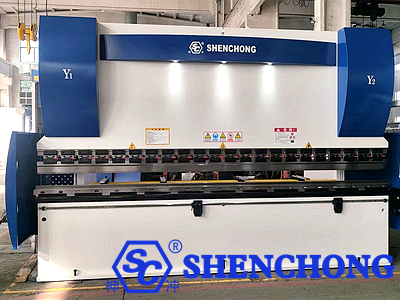

As a core piece of equipment in sheet metal forming, the CNC press brake bending machine operational accuracy, stability, and service life all heavily rely on standardized daily maintenance. Scientific CNC press brake maintenance can effectively reduce malfunctions, stabilize bending accuracy, extend equipment life, and increase production capacity.

Maintain key indicators such as Y1/Y2 synchronization accuracy, back gauge repeatability, and slider parallelism.

Avoid sudden shutdowns caused by hydraulic system contamination and wear of critical bearings.

Lubrication, cleaning, and calibration can extend the overall machine lifespan by 25%–40%.

Avoid potential risks such as grating failure, excessive oil temperature, and loose fasteners.

Clean the worktable and slider area of metal filings, dust, and oil stains.

Observe whether the hydraulic oil temperature is within the normal range of 30–55℃.

Check for abnormal sounds, vibrations, and oil leaks.

Maintain a light oil film in the guide rail and slider area; if there is automatic lubrication, check that the oil level is sufficient.

Check whether the mold clamping bolts are loose.

Check whether the light curtain protection, foot switch, and emergency stop switch are responding normally.

Check whether the protective cover and access control switch are in an effective state.

Check if the hydraulic oil level in the tank is within the normal range.

Inspect the hydraulic line joints for leaks.

Check if the cooling system (fan/water cooling) is working properly.

Clean the lead screw and guide rails, ensuring they are free of dust and metal shavings.

Check the gear and belt tension for proper function.

Check if the electrical control cabinet is dry and free of metallic dust.

Check for loose guide rail encoders and cables.

Comprehensively inspect the machine body bolts and connectors for looseness.

Check the slide limit switch to ensure reliable operation.

Inspect the mold for wear and confirm the consistency of bending angles.

Check the cleanliness of the proportional servo valve interface and the cable fixing status.

Observe for abnormal synchronization errors (normally ≤0.02–0.03mm).

The service life of hydraulic oil is generally 4000–6000 hours; replace earlier based on oil quality testing.

Clean the oil tank and filter, and check for blockage in the return oil filter.

Replace with new hydraulic oil (high-quality anti-wear hydraulic oil 46# or manufacturer-specified model recommended).

Check driver and servo motor temperatures and fan operation.

Calibrate the grating ruler zero position and check encoder reading deviation.

Perform slider parallelism test (within 0.02–0.05mm).

Calibrate Y1/Y2 synchronization accuracy and bending angle deviation.

Retest X/R/Z axis repeatability accuracy (within 0.05mm).

Depressurize before disassembly: Before inspecting hydraulic lines or valve blocks, always turn off the power and release system pressure.

Maintain stable oil temperature: 25–55℃ is optimal; prolonged high-temperature operation is not recommended.

Select the correct hydraulic oil: Generally use 46# anti-wear hydraulic oil (use 32# in cold regions).

Keep the oil change environment clean: Prevent iron filings and dust from entering the oil tank; use an oil filter when changing the oil.

Check the hydraulic oil level daily: Maintain it at 1/2–3/4 of the sight glass.

Power off before opening the cabinet: The electrical control cabinet must be shut down and powered off for 5 minutes before operation.

Use dry air to clean dust from the electrical cabinet to prevent condensation.

When inspecting wiring terminals, avoid using excessively long metal tools to touch adjacent terminals.

Never plug or unplug network cables or communication cables while the CNC system is powered on during maintenance.

Guide rails and lead screws must be kept lubricated; operation with dust is strictly prohibited. When changing molds, the slide block must be lowered to its lowest point or supported to prevent accidental slippage.

Mold fastening bolts must be tightened to the specified torque.

No objects should be piled up in the back gauge movement area to avoid interference or collisions.

A "Equipment Under Maintenance" warning sign must be displayed during maintenance.

When two or more people are working, they must maintain visible communication.

The light curtain protection must be properly enabled and short-circuiting is prohibited.

When calibrating angles or slide blocks, hands or measuring tools must not be placed in the mold gaps.

When inspecting solenoid valves, avoid approaching the sensing parts to prevent sudden activation.

Do not use inferior or mixed oils.

This will cause proportional valve blockage, large synchronization errors, and premature pump wear.

Do not disassemble joints or valve blocks under pressure.

This can easily cause oil spraying, injury, or damage to seals.

Do not continue operating when the hydraulic oil is severely contaminated.

Immediate action is required if blackening, emulsification, or fine foaming occurs.

Do not operate with low oil levels for extended periods.

This will cause cavitation, pump noise, and vibration.

Do not clean the electrical cabinet or wiring while the circuit is energized.

This can easily cause short circuits, electric shock, or even burn out the CNC system.

Do not blow the electrical cabinet with a damp cloth or a high-humidity air source.

This will cause the circuit boards to become damp.

Do not use non-original system parameter backup files.

This will affect Y1/Y2 synchronization and back gauge accuracy.

Do not run the lead screw or guide rails without lubrication.** This will accelerate wear and affect accuracy. Do not strike the mold with a hammer or forcibly install the upper mold. This can easily cause mold base deformation and uneven sliding load.

Do not bend the machine without locking the upper mold. This can cause equipment damage and serious danger.

Do not bend the machine under uneven load for extended periods. This will cause asymmetrical wear on the frame and cylinders.

Do not allow unauthorized personnel to accidentally activate the foot switch.

Do not continue production around the light curtain or safety protection.

Do not pile tools or measuring instruments on the machine.

Do not enter the machine tool when the sliding block is in the upper position.

Do not stand in front of the mold or in the spring back area of the bent part.

Maintenance Cycle | Key Items |

Daily | Cleaning, lubrication, oil temperature, mold tightening, safety devices |

Weekly | Liquid level, piping, back gauge guide rail and lead screw, electrical control cabinet cleaning |

Monthly | Structural tightening, limit switch inspection, synchronization system inspection |

Yearly | Hydraulic oil replacement, electrical system inspection, overall machine precision calibration |

Bending angle deviation reduced by 20–40%

Downtime due to malfunctions reduced by 50%

Hydraulic pump station lifespan increased by 30%

More stable back gauge repositioning, shortening setup time by 20–30%

Related articles for reference:

How To Choose The Best Press Brake Tooling?

CNC Press Brake Operation Practices For Beginners

Press Brake Bending Machine Latest Buying Guide