The steel profile automated storage system is a highly efficient warehousing equipment that integrates intelligent storage, automated inbound and outbound processes, and information management. It is specifically designed for storing long metal materials such as H-beams, channel steel, angle steel, round steel, square steel, and steel pipes.

Through automated control and information management, this system achieves high-density storage, intelligent scheduling, and safe management of steel profiles, and is widely used in industries such as steel structure processing, machinery manufacturing, automobile manufacturing, and building materials.

The steel profile automated storage system mainly consists of the following components:

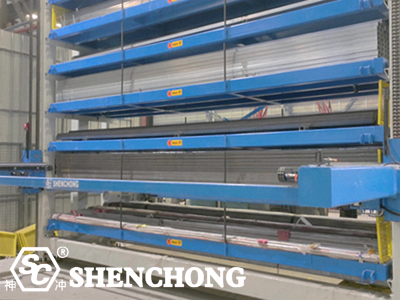

Utilizing a heavy-duty steel structure design, it can be arranged in multiple layers (commonly 6-12 layers).

Each layer is equipped with pallets or crates, with a high load-bearing capacity (0.5-5 tons/compartment).

Responsible for automatically completing the storage and retrieval of profiles.

Employs servo drive + laser positioning to ensure precise placement.

Includes chain conveyors, roller conveyors, transfer carts, etc., used for transferring goods between the inbound/outbound gates and the stacker crane.

Achieves precise inbound and outbound operations through PLC automated control.

WMS is responsible for inventory management, task scheduling, and data tracking.

WCS enables real-time communication and motion control with the mechanical equipment.

Item | Parameters |

Model | 6015 Steel Profile Warehouse |

Number of Layers | 10 layers |

Single Layer Load Capacity | 5 tons |

Single Cell Size | 6000mm × 1500mm |

Storage Type | H-beams, square tubes, round tubes, channel steel, etc. |

Control Method | PLC + Touchscreen Automatic Control |

System Accuracy | ±2mm |

The operator inputs profile information or scans barcodes via a terminal.

The WMS system assigns storage locations.

The stacker crane automatically delivers the profiles to the designated storage location.

The system automatically records storage information.

The operator issues an outbound command through the system.

The stacker crane retrieves the profiles from the designated storage location.

The conveyor system delivers the profiles to the outbound port or the next processing step.

The system automatically updates the inventory status.

The automated steel profile storage system integrates multiple advanced technologies, including mechanical automation, information management, intelligent control, and safety monitoring, achieving automated storage and retrieval, high-density storage, and intelligent scheduling management of steel profiles. The system as a whole has the following significant technical features:

Utilizing a standardized three-dimensional rack structure, it supports multi-level (6-12 layers) expansion, flexibly matching different factory heights and load-bearing requirements.

Single-layer load-bearing capacity can reach 0.5-5 tons, suitable for various steel profiles (such as H-beams, square tubes, round tubes, channel steel, etc.).

Modular design facilitates installation, maintenance, and future expansion.

Employing servo drive + laser positioning technology, the positioning accuracy can reach ±2mm.

The stacker crane, lifting machine, and traversing mechanism are all precisely controlled by PLC, enabling continuous and stable operation.

Short inbound and outbound time (≤30 seconds per transaction), significantly higher efficiency than manual operation.

PLC Control System: Responsible for mechanical motion control and safety protection.

Warehouse Control System (WCS): Coordinates the operation of stacker cranes, conveyor lines, and other equipment.

Warehouse Management System (WMS): Enables inventory information management, task scheduling, traceability query, and statistical analysis.

It can interface with MES and ERP systems to achieve enterprise-wide information linkage.

Supports barcode/RFID identification and automatically reads profile information.

Real-time recording of the entry, exit, and storage location of each material.

Achieves material traceability and intelligent classification management.

The system has three operating modes: automatic, semi-automatic, and manual.

Automatic mode allows for unattended operation; semi-automatic/manual modes facilitate maintenance and troubleshooting.

Equipped with multiple safety devices including photoelectric detection, anti-collision limit switches, overload protection, and power-off braking.

Critical mechanisms employ redundant safety protection logic to ensure equipment and personnel safety.

All motion paths are monitored and interlocked in real time via PLC.

The servo system's automatic energy feedback technology effectively reduces energy consumption.

Optimized mechanical structure design and transmission chain layout achieve low-noise operation (≤70dB).

The equipment automatically enters energy-saving mode in standby mode.

It can be linked with automatic feeding lines, sawing machines, laser cutting machines, and robotic gripping systems to form intelligent processing units.

It can be connected to the factory's digital platform to achieve an integrated production layout of intelligent warehousing and intelligent processing.

Suitable for normal temperature, low temperature, or dusty environments.

Customized anti-corrosion, dustproof, and oil-proof special structures are supported.

- Positioning Accuracy: ±2mm

- Single Compartment Load Capacity: 500kg~5000kg

- Number of Layers: 6~12 layers, customizable

- System Control Method: PLC + Touch Screen + Industrial Bus

- Identification Method: Barcode / RFID

- Interface Protocol: Compatible with ERP / MES systems

- Safety Protection: Photoelectric detection, anti-collision, overload protection

- Operating Noise: ≤70dB

- Ambient Temperature: -10°C ~ 45°C

The automated steel profile warehousing system, with intelligence, efficiency, and safety as its core, realizes centralized management, intelligent scheduling, and automatic loading and unloading of profiles, significantly improving warehousing efficiency and space utilization. It is an important piece of equipment for enterprises to move towards intelligent factories and digital production.

The steel profile automated storage system, through the integration of mechanization, informatization, and intelligence, realizes the transformation of traditional profile warehousing into digital, flexible, and unmanned systems.

Its key technical features include:

- High-density storage

- High-precision control

- High operational efficiency

- Highly intelligent management

- High operational safety

System performance characteristics summary:

- High load-bearing capacity: Single cell can bear up to 5 tons, suitable for heavy steel profiles.

- High space utilization: Three-dimensional layout increases storage capacity by 200%–500%.

- High inbound/outbound efficiency: Stacker cranes operate fully automatically, reducing inbound/outbound.

- High-precision control: Laser positioning and servo control ensure ±2mm accuracy.

- Highly intelligent management: The WMS system enables real-time inventory monitoring and traceability.