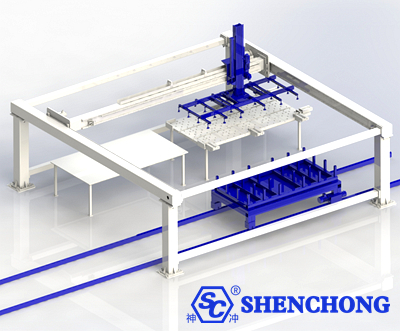

Gantry robots are industrial automation devices with a gantry frame and linear axes (X/Y/Z) as their core structure. They are widely used in heavy-duty handling, loading and unloading, palletizing, warehousing, and machine tool lines.

A gantry robot is an industrial robot with a steel or aluminum gantry structure as its main body, achieving spatial positioning and material handling through X/Y/Z linear motion axes.

Essentially, it is a "programmable, high-precision, multi-axis linkage linear automated material handling system."

- Cantilever/Single-beam/Double-beam structure

- High-strength welded steel structure or industrial aluminum profile

Gantry Robot Features: High rigidity, low vibration, suitable for large spans

Axis | Functions | Common configurations |

X-axis | Long-stroke main traverse | Gear and rack/synchronous belt |

Y-axis | Lateral positioning | Gear and rack/lead screw |

Z-axis | Lifting and lifting gripping | Lead screw/linear module |

- Servo motor + reducer

- PLC / motion controller

- Supports multi-axis synchronous and interpolation motion

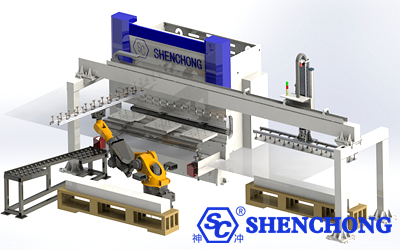

Gantry robots can be interfaced with:

- Laser cutting machine

- CNC plate shearing

- Vacuum suction cup (sheet metal, thin parts)

- Mechanical gripper (profiles, pipes)

- Electromagnetic clamp (carbon steel)

- Custom composite clamps

Item | Common range |

Load capacity | 10 kg-2000 kg |

Positioning accuracy | ±0.05-±0.1 mm |

Repeatability | ±0.03-±0.08 mm |

Operating speed | 1-3 m/s |

Continuous operation | 24-hour continuous operation |

The advantage of gantry robots lies in their "stable accuracy that does not decrease over time".

Gantry robots use X/Y/Z linear axes:

- Simple motion model

- No multi-joint superposition errors

- No attitude calculation drift

Minimal accuracy decay after long-term operation, ideal for 24-hour continuous production.

- Gantry steel structure

- Load force is directly transferred to the ground

- Does not rely on "cantilever posture"

Comparison with six-axis robots:

Six-axis = "The longer the arm extends, the more shaky it becomes"

Gantry = "The larger the structure, the more stable it is"

- Single-axis stroke can reach 10–20 m

- Multi-station operation can share a single system

- No need for multiple robots to share the workload

This is something articulated robots cannot economically achieve.

- Load range: tens of kilograms → several tons

- No need for expensive high-end robots

- Only require strengthened structure and drive system

- Heavy loads do not significantly increase control complexity

While peak speed may not be the fastest, it offers:

- Shortest straight path

- No complex obstacle avoidance

- No deceleration protection zone

In regular material handling,

In regular material handling, the single-piece cycle time is actually more stable and faster.

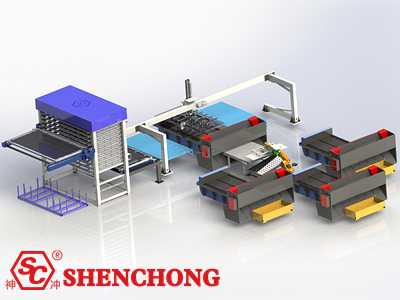

- One gantry serves 2-6 machine tools

- Synchronous loading and unloading

- Capable of "assembly line-style cycle time"

- Six-axis robots often only offer "single-machine service"

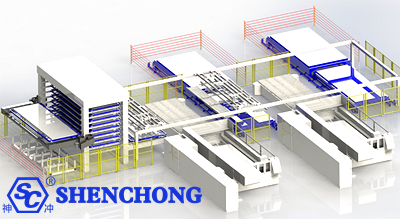

Truss structure = "automation skeleton"

Ideally suited for building:

- Sheet metal storage

- Profile storage

- 3D storage system

- Unmanned production lines

Serves as the "load-bearing main beam" of automation systems

- Linear coordinate control

- PLC can handle it

Few points of failure, intuitive troubleshooting

For factories: "Repairable, easy to repair, and quick to repair"

In scenarios with large travel:

- Truss = 1 set

- Six-axis = Multiple units + safety fence

Overall cost is actually lower

- Long lifespan of structural components

- Fewer vulnerable parts

- No reliance on expensive original equipment manufacturer (OEM) maintenance

The cost advantage will continue to amplify over a 5-10 year usage period.

- Stability

- Continuity

- Predictability

- Large-format sheet metal

- Heavy workpieces

- Multi-machine lines

- Unmanned production lines

Dimensions | Truss type | 6 axis type |

Working range | ⭐⭐⭐⭐⭐ | ⭐⭐⭐ |

Load | ⭐⭐⭐⭐⭐ | ⭐⭐⭐ |

Accuracy and stability | ⭐⭐⭐⭐ | ⭐⭐⭐ |

Flexibility | ⭐⭐ | ⭐⭐⭐⭐⭐ |

Large workstation cost | ⭐⭐⭐⭐ | ⭐⭐ |

Limitations | Notes |

Limited flexibility | Not suitable for complex 3D trajectories |

Large footprint | Factory layout needs to be planned in advance |

Long customization cycle | Non-standard product |

Conclusion: Suitable for "regular, repetitive, and large-scale" tasks.

Different types of industrial robots possess unique advantages and limitations, and their technical characteristics directly determine the suitable application scenarios. Gantry robots are no exception, their applicable boundaries need to be comprehensively evaluated from five core dimensions: payload, movement speed, working range, flexibility, and equipment size.

Payload capacity is the most significant technological advantage of gantry robots. Their structural design is similar to industrial cranes, using a large-span metal truss to construct a rigid mechanical frame capable of supporting the enormous loads of large sheet metal equipment and heavy work pieces. They are perfectly suited for heavy-duty operations such as heavy material handling and loading/unloading large sheet metal parts.

However, this characteristic also brings certain limitations: for light-duty tasks such as small assembly and precision parts sorting, while gantry robots can complete the tasks, there is a problem of functional redundancy. Enterprises must pay additional costs for the underutilized heavy-duty capacity, making it less than optimal from an economic perspective.

The movement speed of a gantry robot is primarily determined by the performance of its drive motor and the effective load. Due to its size and structure, its operating speed can cover a wide range from a few centimeters per second to several meters per second, offering strong speed adjustment flexibility.

This advantage stems from its unique transmission design:

Unlike articulated robots, the drive motor and gearbox are not integrated into the robot body. They can be flexibly configured using various transmission mechanisms such as ball screws, racks and pinions, and synchronous pulleys. Furthermore, the external mounting of the gearbox and motor further enhances the adaptability of the transmission system.

It is important to note that speed and payload are inversely related:

Higher payload requirements necessitate heavier structural components and larger transmission ratios, which significantly limits the robot's maximum operating speed. Conversely, high-speed robots often struggle to handle heavy loads. Specific selection should be based on the actual speed and payload requirements of the application.

Operating range is the most prominent competitive advantage of gantry robots. Compared to other types of robots such as articulated and SCARA robots, their coverage area is almost unrestricted by their own structure, determined only by the size of the on-site installation space.

From small workstations of a few square meters to large production workshops the size of a football field, gantry robots can achieve full-area coverage by extending the gantry length. This characteristic makes them the preferred solution for large-span operation scenarios such as material handling in large workshops, goods storage and retrieval in automated warehouses, and loading and unloading on large sheet metal production lines. If the task requires coverage of a long-distance operating area, gantry robots are a highly cost-effective choice.

While the rigid structure of gantry robots grants them heavy-load and large-span capabilities, it also limits their motion flexibility. Their movement trajectory is primarily based on XYZ three-axis Cartesian coordinates, mainly achieving simple vertical up-and-down and horizontal translation movements, making it difficult to perform complex spatial posture adjustments.

Therefore, gantry robots are less adaptable to scenarios requiring the robot to navigate around obstacles or operate from the side or below the workpiece. For example, articulated robots are more advantageous for tasks requiring flexible adjustment of working posture, such as multi-angle welding and grinding complex curved surfaces.

A typical workflow for a gantry robot is:

Move to above the workpiece → Descend vertically → Perform operation → Ascend vertically → Move to the next workstation.

Gantry robots are among the larger types of industrial robots. Even smaller models have gantry structures that occupy considerable vertical and horizontal space.

In large-scale operations, this size characteristic can be an advantage, allowing for full coverage of the ground work area through elevated gantry installation, without occupying valuable ground space. However, in space-constrained scenarios, lateral or longitudinal size limitations can lead to difficulties in gantry integration. Nevertheless, because they are typically installed suspended at height, they are compatible with the spatial layout of most production scenarios. Only when existing factory buildings have complex elevated infrastructure should the feasibility of gantry installation be assessed in advance.

Gantry robots are industrial robots that use steel or aluminum trusses as their main structure and achieve spatial positioning and material handling through X/Y/Z linear motion axes. Gantry robots are not necessarily more flexible, but they are better suited for scenarios involving heavy loads, large spans, and long-term operation.

- Gantry Frame: Steel structure or aluminum profile, high rigidity, long stroke

- Linear Motion Axes (X/Y/Z): Gear rack/pinion screw/synchronous belt

- Servo System: High-precision positioning and synchronization control

- End Effectors: Suction cups, grippers, electromagnetic clamps, etc.

- Control System: PLC/motion controller, compatible with MES

- Large stroke, heavy load: Suitable for heavy parts such as sheet metal, profiles, and molds

- High repeatability: ±0.05~0.1 mm (depending on configuration)

- Stable and durable: High structural rigidity, 24-hour continuous operation

- Highly customizable: Number of axes, stroke, load, and workstations can be designed to meet specific needs

- High cost-effectiveness: Superior to six-axis robots in large-scale material handling scenarios

- Sheet metal industry: Laser cutting/shearing/ Bending and loading/unloading

- Machining: CNC, machining center automatic loading/unloading

- Storage System: Sheet metal warehouse, profile warehouse, pallet warehouse

- Welding/Assembly: Linear trajectory, high consistency process

- Palletizing and handling: Regular path, repetitive operation

Gantry robots are the most reliable and economical automation solution for heavy-duty, large-span, and standardized production lines.

Prioritize gantry robots if:

- Workpieces are heavy

- Large strokes

- Repetitive and regular movements

- Seeking stability and cost-effectiveness

Choose articulated robots if:

- Complex trajectories

- Diverse workpieces

- Limited space

If you have questions about whether your production line is suitable for gantry robots, or have related equipment automation needs, please contact our technical consultants and sales team at any time to obtain professional customized solutions.