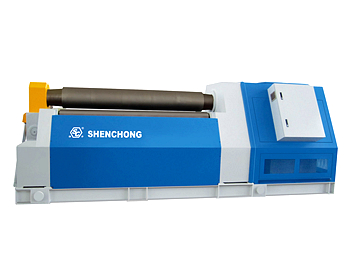

4 Roller Plate Bending Roll Machine is the first choice of the durable intelligent equipment for profile and arc rolling. Four-roll bending rolling machine can mass produce precision parts effectively and decrease process cost per part. The left and right frames are the main body of the four roller bending machine, and the welding structure is adopted and installed on the whole welding base. All the operations perform on the operating table.

Intelligent Manufacturing Redefine Your Future!

Four-roller plate rolling machine is used to make pre-bending and rounding of cylinders in the pressure vessel, machinery, water and electricity, construction and other industries, and has the functions of rounding and leveling.

The lifting of the rollers on both sides is driven by hydraulic cylinders, the lifting displacement is controlled by computer, and it is automatically leveled with high synchronization accuracy. The tipping and resetting of the tipping frame is driven by hydraulics.

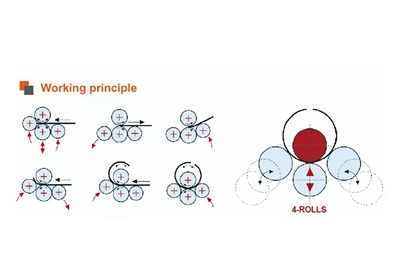

The bottom roller is vertically lifted and the side roller is tilted. In pre-bending, the lower roll rises and clamps the steel plate, and the side rolls rise obliquely to achieve pre-bending at the end of the sheet.

- The upper roller is the main roller, the lower roll and the side roll are driven rollers. The rotation is driven by the friction force between the steel plate and the rolls.

- The upper roller is fixed only for rotation motion, and it does not move up and down.

- The lower roll and the side roll can be moved up and down, all of which are moved up and down by its left and right cylinders.

- Turned and reset of the front roller bearing body is carried out by the oil cylinder.

- Each 4 roller bearing body and oil cylinder are installed in the frame of the left and right ends.

- Structure overview

This machine is a four-roller plate bending machine with fixed upper roller position, lower and side rollers can move up and down, upper and lower rollers are hydraulically driven, and the rotation of the side rollers is driven by the friction between the steel plate and each roller. The lower roller and the side roller are moved up and down by the oil cylinders at both ends. The turning and resetting of the front bearing body of the upper roller is carried out by the oil cylinder. Each roller bearing body and oil cylinder are installed in the frame at the left and right ends.

- Upper roller device

The upper roller device is composed of upper roller, upper roller bearing, hydraulic motor, etc. The upper roller is designed in a drum shape. Generally, the load factor of the upper roller is 0.7 uniformly distributed load to compensate for the deformation disturbance, which greatly improves the straightness of the product. Roll hardness treatment is divided into two steps, quenching and tempering hardness HB240-300, surface medium frequency quenching HRC45-55.

- Lower roller device

The lower roll device is composed of the lower roll, the lower roll chock, the bearing, and the lower roll cylinder. The lower roll is quenched and tempered HB240-300, and the surface is medium-frequency quenched HRC45-55.

- Side roller device

The side roller device is composed of two side roller bearing seats, bearings, side roller cylinders, etc.; side rollers are quenched and tempered HB240-280, and the surface is quenched by HRC45-55.

- Tipping device

The tipping device is composed of a ram, a tipping cylinder, etc.

The overturning of the overturning device facilitates the removal of the product along the axial direction of the roller.

- Machine guard

There are detachable protective covers around the hydraulic workstation and the space under the work rolls. The large protective covers around the hydraulic work are equipped with glass doors and windows for easy observation and adjustment of the hydraulic valves, as well as easy maintenance. See the following figure:

- Left and right supporting racks and upper supporting racks (optional accessories)

When the coiling machine is rolling a workpiece with a large diameter, the accuracy of the coil will be affected due to its own weight. It is difficult to ensure the overlap of the interface when the workpiece is welded. Therefore, the rolling machine is equipped with left and right support and upper support devices.

The left and right supporting racks are composed of oil cylinders and brackets.

The upper support frame is composed of an oil cylinder, a bracket, a roller, a beam, etc. The bracket is installed on the top of the right frame, and the lifting of the beam is controlled by the oil cylinder to support a large diameter cylinder.

- The upper roller is main drive roller, bottom roller and two side rollers make vertical movement to tighten the plate.

- Vertical movement close to upper roller adjust circle radius.

- Small straight edge of pre-bending.

- High rolling precision.

- Roll taper workpiece with full generatrix

- Rollers moving position control by computer.

- Highest rolling efficiency and capacity.

Compared with the symmetric three roll bending machine

CNC 4 roll plate bending machine can directly bend the end of the sheet directly without any other equipment, and the remaining straight side is smaller.

Compared with the asymmetrical three roll bending machine

CNC 4 Roller Plate Bending Roll can roll the plate sheet without turning it. It not only improves the efficiency, but also ensures the quality of the work piece, and the process is simple, the operation is convenient, and the labor intensity of the workers is lightened.

- Operate upper roller to make the distance between up buss and down buss a little larger than plate thickness, then operate the feeding side roller to make distance between side roller’s up buss and down roller's down buss keep in same level, lastly operate the other side roller to make its position between up and down roller.

- Feeding: horizontally feed the plate to make plate end touch with ventro-side roller wholly, then low the side roller to original position.

- Clamping plate tightly and start pre-bending.

- Use ventro-side roller to pre-bend the other side of plate, after finish pre-bending the left side, then low the back side roller to original position; then operate the upper roller to bend the plate to the right position shown on drawing, then stop the upper roller, lastly operate the ventro-side roller up to bend the other side of plate.

- Principium bending: adjust ventro and back side roller to appropriate position, operate the roller to do principium bending.

- Figuration bending: adjust ventro and back side roller to appropriate position, operate the upper roller to do figuration bending.

- Take out the workpiece: after finished whole bending, low the down roller to the lowest position, then workpiece gradually lower with the two side rollers to an appropriate position, overturn the head, lifting the workpiece, remember to keep same level with upper roller to discharge the workpiece.

- Left and right framework

- Overturn head

- Upper roller part

- Down roller part

- Side roller part

- Connecting part

- Welded base

- Driven part

- Hydraulic part

General overview:

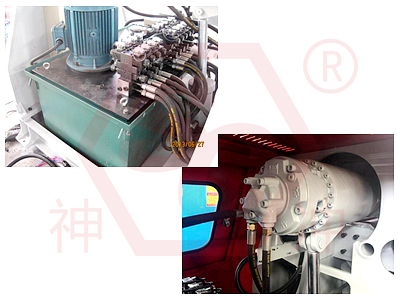

The hydraulic system completes the following actions: driving the hydraulic motor to rotate; driving the oil cylinder to make the lower roller move up and down; drive the rollers on both sides to make the tilting up and down movement; control the dumping cylinder to move up and down.

The hydraulic system consists of gear pumps, valve blocks, fluid connections, hydraulic accessories, etc.

The hydraulic valve adopts superimposed valve series, with simple pipeline layout and convenient maintenance and debugging.

The system consists of three circuits, overpressure protection and pressure regulation circuit, synchronization circuit and speed circuit.

The pressure regulating circuit regulates the working pressure of the system through the main relief valve. The working pressure of the system is 19.5MPa.

Synchronous circuit uses a shunt throttle valve to synchronize the rising and falling coarse steps of the lower roller side roller, and the throttle valve adjusts up and down; the displacement sensor detects, and the upper roller has high synchronization accuracy.

The speed loop controls the overturning and resetting of the bending roll machine on the overturned side, and adjusts the loop throttle speed through the throttle valve.

Protections:

The rising and falling of the lower roller and the side roller are respectively provided with overflow valves for pressure limit protection.

The hydraulic components are selected from high-quality and reliable brand products to ensure the stable and continuous working of the hydraulic system for a long time.

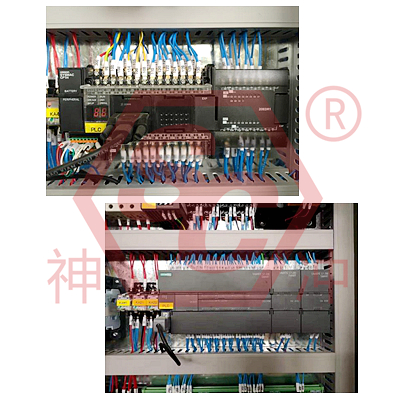

- Control System

Select either Touchiwin or SIEMENS touch screen.

Choose one of Omron or Siemens intelligent PLC.

General overview:

The control system uses touchiwin (or SIEMENS) color touch screen display, and uses Omron (or Siemens) intelligent PLC and the corresponding input, output and storage modules.

This configuration has been proved in the process of supporting various users for a long time: it has the advantages of strong anti-interference ability, long service life, earthquake resistance and stable operation.

The sensor adopts a high-precision absolute displacement sensor to ensure the position accuracy and realize the position monitoring of each roller, even if the power is off, there will be no data deviation. The main components of the strong electric parts are selected from the products of famous and high-quality enterprises, and have the characteristics of long life and long trouble-free time.

Digital display function:

The digital display system has the functions of real-time monitoring of the rolling process, power-off memory and other functions, and the man-machine interface is intuitive and clear in Chinese. The display screen displays the upper and lower displacement (Yg, Yf) of the main cylinder of the lower roller side roller. Through the system operation input and LCD display, functions such as editing and modifying the parameters of the rolling workpiece can be realized. The industrial controller PLC automatically detects the lower roller The two ends of the side rollers are positioned and controlled to ensure synchronization accuracy.

Intelligent automatic mode function:

The "automatic CNC four-roller roll bending machine control system" developed by our company can realize one-key start, automatic material matching and automatic forming and rolling at one time. Input the process steps of the rolling workpiece into the system and store it to form a rolling program. When encountering the same batch and the same specification of the workpiece, directly call the program and press the start button to directly roll the workpiece directly, which is convenient and fast, and the work efficiency is high. This system can store hundreds of adjustment programs and number them. The system also has a manual operation mode, and users can choose manual/automatic operation.

It can also be equipped with automatic loading and unloading system to get automated production.

CNC plate rolling machine has a strong ability of rolling small circle, the general rolling machine with the highest rolling efficiency and ability, which is suitable for higher standards.

Used in aviation Industry and high precision machinery manufacture etc…

As the experienced CNC plate rolling machine factory, Shenchong exported four roller plate rolling machine to more than 70 countries globally over 20 years. We have different models of 4 rolls sheet metal rolling machine for sale, contact us today!

Q: How to get a 4 roller plate rolling machine quotation from SHENCHONG?

A: Every customer can get direct sheet metal plate 4 roller rolling machine price from us. Shenchong is one of the largest plate bending roll manufacturers, and we can offer you detailed technical proposal and price. Please provide us your plate material type, max thickness and max width. Also, it will be helpful if you can send us your workpiece drawings or related bending requirements.

Q: What’s the 4 roller plate bending roll machine shipping cost from China to your country?

A: We can send the plate rolling machine to your port or door address by sea or rail, and so please kindly tell us your nearest port. We have reliable shipping agent to insure the safe convenient and time delivery.

Q: Do you accept LC payment?

A: Yes, normally our payment is 30%+70% T/T, LC payment is also acceptable. Our 4 roller plate rolling machine price is affordable, contact with us today!

Q: Do you have four roller plate roll bending machine installation and training service?

A: Yes, Shenchong is a reliable China plate bending roll manufacturer with full exporting experiences. Installation Services are available with all our machines. We dispatch technician to customer's factory for installation and pre-operation of the cnc plate roll bending machines. (Customers only need to pay the airfare and hotel)

We provide detailed machine user manuals and train videos, or customers can set a video call with our sales and engineers. Our technician is available to your factory and offer training of how to use our 4 roller plate rolling machines. The buyer needs to afford plane tickets. As well, you may send your technician to our company to learn how to operate machines.