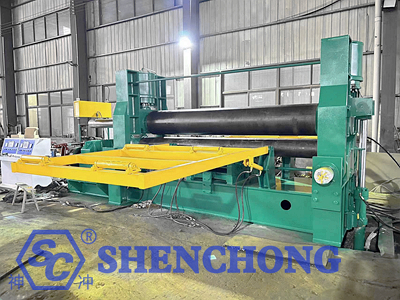

3 rolls bending machine is a basic forming equipment used to roll metal sheets into cylinders, arcs, or cones. It is one of the most common rolling machines in sheet metal workshops. So, how do you maintain it? Below is a "3 Rolls Bending Machine Maintenance Manual (Detailed and Complete Version)," suitable for workshop implementation, equipment management systems, after-sales delivery materials, and training manuals.

* Ensure rolling accuracy and rounding quality

* Extend the service life of the main roller, bearings, and hydraulic system

* Reduce the failure rate and avoid sudden shutdowns

* Ensure operational safety and equipment stability

* Lubrication priority, cleanliness is fundamental

* Preventive maintenance > Fault-based repair

* Small problems resolved overnight, major hidden dangers resolved within the shift

* Whoever operates, inspects; whoever repairs, is responsible

* Check if the main power supply and voltage are normal

* Check if the emergency stop button and foot switch are sensitive

* Check if the protective cover and limit switches are intact and effective

* Abnormal: Do not start the 3 rolls bending machine

* Oil level above 2/3 of the oil level indicator

* No leakage in oil pipes, joints, and cylinders

* Normal hydraulic oil color (not white, not emulsified)

* Oil film present in the bearing positions of the upper roller, lower roller, and side rollers

* Good lubrication of the slider and guide rails

* Dry friction → Oil must be added before starting the 3 roller bending machine.

* Roller surface free of iron filings, welding slag, and hard objects.

* Roller surface free of obvious indentations and scratches.

* Frame and bearing seat bolts are not loose.

Motor and hydraulic pump operate smoothly.

No screeching, knocking, or periodic abnormal noises.

Sheet material feed is smooth and does not deviate.

Three rollers rotate synchronously without shaking.

The rounding process is uniform, without sudden "material jumping".

Pressure gauge is stable and does not fluctuate drastically.

Oil temperature is normal (the oil tank is not hot to the touch).

If any abnormality is found: Stop the machine immediately for inspection.

Clean iron filings and scale from the roller surface.

Wipe oil stains from the slider, guide rails, and three rolls bending machine body.

Do not allow metal filings to remain overnight.

Return the upper and side rollers to the neutral position.

Unload the hydraulic pressure. Return the operating handle to the zero position.

Stop the hydraulic pump → Disconnect the main power supply. Lock the electrical cabinet. Keep the environment dry and clean.

Check the oil level daily; it's cheaper than repairing the pump.

Clean roller surface = rolling accuracy. No delays due to abnormal noises.

No compromises on oil leaks.

Forced start with insufficient oil level.

Rolling plates directly with weld slag on the roller surface.

Repeatedly operating under load with sudden stops.

Rolling of extra-thick, extra-wide, or extra-strength materials.

Unauthorized adjustment of hydraulic parameters by non-maintenance personnel.

Items | Inspection Content | Standards |

Power system | Voltage, emergency stop button | Normal and sensitive |

Hydraulic system | Oil level, oil pipes, connectors | No leakage, normal oil level |

Lubrication points | Rollers, sliders | Oil film present |

Three-roller surface | Scratches, indentations | No obvious damage |

Limiting device | Upper and lower limits | Reliable operation |

Check for abnormal noises or vibrations from the hydraulic pump.

Check for sheet material deviation during rolling.

Check for synchronized and smooth roller rotation.

Check for stable system pressure (no frequent fluctuations).

Clean iron filings and oil stains from the roller surface.

Wipe the guide rails and sliders.

Return the upper and side rollers to the center, releasing system pressure.

Disconnect the power supply and lock the electrical cabinet.

Check and tighten:

Main roll bearing seat bolts

Frame connecting bolts

Hydraulic cylinder mounting bolts

Standard:

No loosening, no signs of displacement

Check oil pipes, joints, and valve blocks

Standard: No oil leakage, no "oil dripping"

Oil pipes: No bulging or cracking

Check roll surfaces: For scratches or indentations

Permissible range: No damage affecting the rolling quality

Clean all lubrication points

Refill: Lithium-based grease #2

Key areas:

Upper roller, lower roller, side roller bearings

Slide block, guide rail

Clean or replace: Return oil filter

Check: Oil tank breather for blockage

Observe:

Hydraulic oil color and odor

If emulsification or blackening is found → add to replacement plan

Check the synchronization of left and right side rollers

Verify upper and lower stroke limits

Standard: Consistent movement, no jamming

Inspection Items:

Parallelism of upper and lower rollers

Coaxiality of three rollers

Reference Standard: ≤ 0.2 mm / m

Inspect the cylinder:

Piston rod for scoring

Seal for aging

Standard:

No creeping, no internal leakage

Inspect:

Motor mounting and alignment

Coupling wear

Cleaning: Motor cooling ducts

Recommendation: Use ISO VG46 anti-wear hydraulic oil.

Operation: Drain oil → Clean oil tank → Replace with new oil.

Requirement: Do not mix different brands of oil.

Inspect: Temperature rise, radial clearance.

Abnormalities: Noise, overheating → Replace.

Tighten terminal blocks.

Inspect contactor and relay contacts.

Clean the inside of the control cabinet.

Measure roll diameter wear

If necessary: Grind or replace rolls

Inspect:

Hydraulic pump

Relief valve, synchronizing valve

Calibrate system pressure

Inspect:

PLC/control system parameters

Safety circuits, limit devices

Backup:

Control parameters, programs

Weekly | Key Points |

Monthly | Fastening, oil leakage, roller surface |

Quarterly | Lubrication, filter element, synchronization |

Semi-annually | Precision, hydraulic cylinder, motor |

Yearly | Oil change, bearing, electrical cabinet |

Weekly | Rollers, pumps and valves, system |

Roller surface condition

Roller shaft and bearings

Roller parallelism and coaxiality

Daily: Cleaning, visual inspection

Quarterly: Precision inspection

Yearly: Wear measurement

Remove iron filings and oxide scale from the roll surface daily.

Strictly prohibit welding slag and hard objects from contacting the roll surface.

Do not allow excessively thick or high-strength rolling.

Regularly check the wear of the roll diameter.

No indentations or scratches on the roll surface that affect rolling.

Parallelism error ≤ 0.2 mm/m.

Cornerality is normal, with no localized material chipping.

Problems | Causes | Treatment |

Not perfectly round | Rolls not parallel | Correcting the roller system |

Slippery board material | Roll surface contamination | Cleaning or lightly grinding |

Surface scratches | Hard object caught in | Grinding the roller surface |

Main bearing lubrication

Couplings, gear meshing

Temperature rise and abnormal noise

Monthly: Top up

Semi-annually: Condition check

Replace if necessary

Use lithium-based grease #2

Add grease to 1/2 to 2/3 of the bearing cavity

Avoid overfilling to prevent overheating

Smooth operation

Bearing temperature rise ≤ 40℃

No dry friction noise

Hydraulic oil

Hydraulic pump

Valve assembly, cylinder

Daily: Oil level

Monthly: Filter element

Semi-annually/Annually: Oil change

Recommended hydraulic oil: ISO VG46 anti-wear hydraulic oil

Do not mix different brands

If oil temperature consistently > 55℃, the machine must be shut down

Clear oil without emulsification

Stable system pressure

No cylinder creep or internal leakage

Phenomena | Possible causes |

Unstable pressure | Valve core contamination |

High oil temperature | Filter element blockage |

Asynchronous operation | Synchronization valve malfunction |

Piston rod surface

Seal condition

Stroke smoothness

Quarterly inspection

Immediate handling of any abnormalities

Keep piston rod clean and free from impacts

Replace seals immediately upon discovering oil leaks

Do not operate with faulty components

No surface scoring

Smooth stroke without vibration

No internal or external leakage

Control cabinet

Sensors, limit switches

Motors and frequency converters

Monthly cleaning

Semi-annual inspection

Yearly parameter backup

Keep cabinet dry and dust-free

Do not plug or unplug components while powered on.

Regularly check grounding

Secure wiring

No alarms or malfunctions

Good heat dissipation

Frame welds

Connecting bolts

Deformation

Monthly routine inspection

Annual special inspection

Focus on high-stress areas

Stop machine immediately upon finding cracks

Prohibit prolonged overload operation

Emergency stop button

Travel limit switch

Protective cover

Foot switch

Monthly functional testing

Stop the 3 rolls bending machine immediately upon failure

Do not disable without authorization

❌ Continuing production with damaged rollers

❌ Ignoring oil leaks

❌ Dry running of bearings

❌ Adjusting hydraulic valves by non-professionals

❌ Operating machine despite safety device malfunction