The slitting and cut-to-length composite production line is an efficient and highly automated equipment system in the metal sheet processing industry. It combines the two processing methods of slitting and crosscutting, and can simultaneously complete the longitudinal striping and transverse cutting of the sheet, realizing the production of multiple specifications of the sheet.

In the field of metal processing, efficiency and precision are the core competitiveness of enterprises. With the surge in market demand for small-batch customized and high-precision sheet processing, traditional single-function slitting machines or cut-to-length machines can no longer meet modern production needs. The slitting and cut-to-length composite production line, with its characteristics of "one machine with multiple functions, intelligent and efficient", is becoming the preferred solution for metal processing companies to upgrade equipment and seize the market.

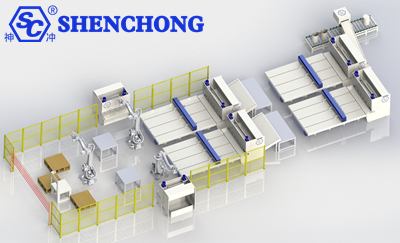

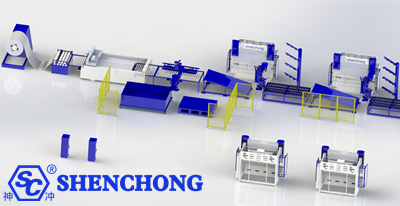

The slitting and shearing production line mainly consists of a loading trolley, an uncoiler, a leveler, a slitting machine, a scrap winding machine, a tension mechanism, a winding machine, a discharge device, a shearing machine, a stacking device, etc.

A typical slitting and shearing production line mainly includes the following parts:

Unroll the coil to prepare for subsequent processing.

Level the plate to eliminate defects such as stress and waves.

Cut the wide coil into several narrow strips according to the set size.

Coordinate the speed difference between the slitting and shearing processes to maintain the material tension.

Cut the slitting strip into the specified length horizontally.

Automatically stack and collect finished panels after cutting.

Achieve automatic control, monitoring and adjustment of the entire line.

The slitting and cut-to-length composite production line is an intelligent continuous processing equipment that integrates unwinding, leveling, longitudinal shearing and slitting, transverse cutting and sizing, and stacking. It can complete multiple processes of traditional multiple equipment at one time. Its core advantages are:

- Process integration: reduce material handling and manual intervention, shorten the production cycle.

- Precision intelligence: using high-precision servo system + AI algorithm, the cutting accuracy reaches ±0.1mm.

- Flexible production: supports fast mold change, adapting to the needs of multiple specifications and small batch orders.

- High-precision tension control: ensure that the plate has no scratches and deformation during high-speed operation.

- Intelligent deviation correction system: laser sensor real-time monitoring, automatic adjustment of cutting path.

- IoT remote operation and maintenance: support equipment status monitoring, fault warning and data analysis.

A production line has both longitudinal striping and transverse length-fixing functions, replacing the traditional separation processing technology.

Suitable for fast switching production of multi-specification plates, significantly improving production line utilization and delivery cycle.

High-precision knife axis positioning and servo control technology ensure that the cutting size tolerance can be controlled within ±0.3mm.

A closed-loop tension control system is used to achieve synchronous coordination between longitudinal shearing and transverse cutting, eliminating plate warping and scratches.

Full-process PLC intelligent control, can store multiple processing programs, and switch specification parameters with one click.

The palletizing system and logistics interface can be seamlessly connected to the smart factory or MES system to improve the level of flexible manufacturing.

Energy feedback drive system reduces energy consumption.

Equipped with multiple safety interlock protection, emergency stop protection and online fault diagnosis functions to ensure operational safety.

- Introduction of visual inspection system: to achieve online plate surface defect detection.

- Integration of industrial Internet and big data: real-time monitoring of production line status, analysis of energy consumption and efficiency.

- Support for unmanned operation: complete loading, receiving, quality inspection and other links through collaborative robots.

- Demand pain points: Refrigerator, air conditioner shell and other parts require high-precision plate cutting, and the traditional process has a low yield rate.

- Solution: The composite production line can process 0.3-3mm galvanized plate and stainless steel plate, achieving a tolerance of ±0.15mm, meeting the strict standards of the home appliance industry.

- Demand pain points: Battery trays and body structural parts have a surge in demand for lightweight aluminum alloy plates.

- Solution: Adapt to high-strength aluminum plate strip cutting, support customized sizes, and increase material utilization to more than 97%.

- Demand pain points: Curtain wall panels and color-coated panels need to quickly respond to diverse customer customization needs.

- Solution: One-click parameter switching, support for plate processing with a width of 50-2000mm and a thickness of 0.5-6mm, and an average daily production capacity increase of 3 times.

- Demand pain points: Solar brackets and frames need to be mass-produced in a standardized manner.

- Solution: Continuous high-speed cross-cutting (up to 60 times/minute), with a single-line monthly production capacity exceeding 5,000 tons.

- Processing range: Select the equipment model according to the thickness and width of common materials (such as 0.2-6mm or thicker specifications).

- Accuracy level: Give priority to servo motor drive + closed-loop control system, and the accuracy must reach ±0.1mm.

- Automation level: Whether it is equipped with automatic feeding, intelligent sorting, stacking robot arms and other modules.

- Energy consumption level: Compare the power consumption per unit capacity and choose an energy-saving drive system.

- Low price trap: Some manufacturers reduce costs by reducing configuration (such as ordinary motors instead of servo motors), resulting in a surge in maintenance costs in the later period.

- Compatibility risk: The equipment cannot be adapted to special materials (such as titanium alloys and high-strength steel), and it is necessary to test the machine in advance.

- Service blind spot: Confirm whether the manufacturer provides localized technical support and spare parts library to avoid downtime delays.

- Technology precipitation: Give priority to brands with more than 10 years of industry experience.

- Customer cases: Check out successful cases in the same industry (such as auto parts and photovoltaic companies).

- After-sales service: response time, warranty policy, remote diagnostic capabilities, etc.

- AI process optimization: Automatically recommend the best cutting solution through historical data learning.

- Digital twin technology: Virtual debugging reduces trial and error costs and improves production efficiency.

- Blockchain traceability: Record the entire process data of sheet metal processing to meet the quality traceability needs of high-end customers.

- Energy-saving design: Use a regenerative braking energy recovery system to reduce energy consumption by 30%.

- Waste reduction technology: Automatic scrap recovery device to achieve "zero waste" production.

Stage | Features | Technical representative |

Mechanized production | Manual operation is the main method | Manual shearing machine, ordinary coil opening machine |

Automated production | Fixed control logic, relying on PLC and sensors | CNC slitting and flying shear system |

Intelligent manufacturing stage | Data-driven, adaptive, collaborative optimization | Intelligent sensing + edge computing + MES integration |

Value dimension | Changes brought by intelligent upgrades |

Productivity efficiency | Equipment OEE increased by 15-30%, switching time reduced by 50% |

Quality consistency | Achieve the pursuit of "zero defects" and reduce rework and scrap rates |

Cost control | Reduce manpower dependence and energy consumption, and improve raw material utilization |

Data visualization | Full-process digital traceability facilitates quality analysis and responsibility definition |

Enterprise competitiveness | Support customer customization, fast delivery, and large-scale flexible manufacturing |