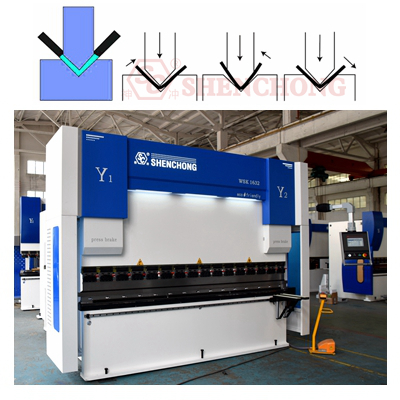

Sheet metal bending is a common process used to process various metal sheets, often used to make mechanical parts, spare parts and other metal products. How to judge whether sheet metal can be bent? How to judge whether the angle of the bent workpiece is qualified?

The length of the bent workpiece has no particular relationship with the model of the bending machine. This is mainly related to v-groove and bending tools.

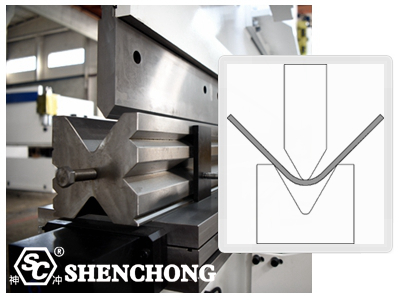

Usually the width of the v-groove is 6 times the thickness of the plate. In other words, the bending line to the top of the plate must be at least 3t.

If the v-groove is too small, the bending coefficient will change. In addition, excessive pressure on the v-groove will affect the service life of the bending machine and mold.

(1) Does the longitudinal direction exceed the maximum bending limit of the rear stopper?

(2) Does the lateral length exceed the maximum length of the press brake machine?

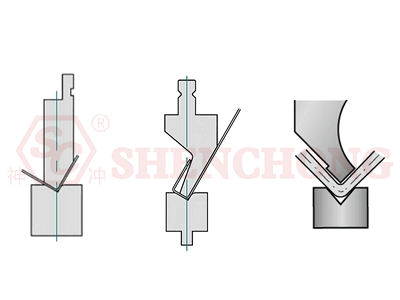

(3) Will the workpiece collide with the tool or machine when bending the second step of the U-shaped workpiece?

(4) After bending both sides of the folding box shaped workpiece, will the product collide with the top when bending the other two sides?

(5) Will the protruding part near the bending line be pressed during bending.

In addition to relying on experience, it is also possible to input the bending mold workpiece into a computer for simulated bending. The bending coefficient refers to the elongation value of the sheet metal during bending. Its value is mainly determined by the plate thickness, bending angle, and the size of the lower mold opening.

For cold-rolled steel plates with a thickness of less than 4mm, the bending coefficient can be considered as a fixed value on the premise of selecting the opening size of the lower die and the same bending angle. The bending coefficient of hot rolled steel plate ≥4mm shall be determined as required.

Common bending data: Generally, the opening size of the lower die is 6 times of the plate thickness. For convenience, when bending 1~2.5mm steel plates, the opening size of the press brake die is 12mm as far as possible. The bending coefficient values of cold-rolled steel plates and hot-rolled steel plates with the same thickness will differ by about 0.1~0.2mm.

In practice, there are several common methods to judge whether the workpiece angle is qualified or not. The following will introduce these methods in detail and provide relevant cases to better understand the application of these judgment methods.

Using physical samples for comparison is a common method. By comparing the bent workpiece with the standard sample, it is possible to visually determine whether the workpiece angle is qualified.

For example, a chassis produced by a certain factory has a sheet thickness of 2mm and needs to be bent into a 90 degree angle. Firstly, prepare a 2mm thick standard sample, and then compare the bent workpiece with the standard sample. If the angles of the two are the same and have a high degree of fit, it can be determined that the angle of the workpiece is qualified.

An angle measuring instrument is a modern measuring instrument that can accurately measure the angle of a workpiece. By placing the angle measuring instrument on the workpiece and recording the measurement results, accurate angle measurements can be made. But for bent workpieces, slight errors are allowed as long as they are within the specified range.

For example, an electronic scale produced by a certain company requires an angle of 80 degrees. During the production process, workers use an angle measuring instrument to measure the bent workpiece, and the measurement result obtained is 79.8 degrees. Based on the measurement results, it can be determined that the angle of the workpiece is qualified.

In some cases, using models for simulation can better determine whether the workpiece angle is qualified. By inputting the data of the workpiece before bending into the model and conducting simulation calculations, the angle of the workpiece after bending can be obtained.

For example, a batch of car body panels produced by a certain factory need to be bent into different angles for processing. Before CNC hydraulic press brake bending, workers used a model for simulation calculations to obtain the workpiece data after bending at each angle. Based on the simulation results obtained, it can be determined whether the bending of the workpiece is feasible and whether the expected effect can be achieved.

In summary, there are multiple methods to determine the feasibility of sheet metal bending and whether the bent workpiece is qualified. The appropriate method can be selected based on actual needs and situations. By comparing physical samples, using angle measuring instruments for measurement, and using models for simulation, the qualification of workpiece angles can be effectively judged, ensuring product quality and process stability.

Click here to know more about Metal Sheet Bending Process