The experience in actual sheet metal processing shows that when the thickness of the general plate is not greater than 6mm, when bending, the inner radius of the sheet metal bending can be directly used as the radius of the plate thickness.

When the plate thickness is greater than 6mm and less than 12mm, the bending radius in the plate is generally 1.25 to 1.5 times the plate thickness. When the plate thickness is not less than 12mm, the bending radius in the plate is generally 2 to 3 times the plate thickness.

When the bending radius is R=0.5, the general sheet metal thickness T is equal to 0.5mm. If a radius size larger or smaller than the plate thickness is required, special tool processing is required.

When the sheet metal drawing requires the sheet plate to be bent at 90°, and the bending radius is particularly small, the sheet plate should be grooved first, and then the sheet metal should be bent. It can also process the upper and lower tools of special bending machine tools.

The bending radius of the sheet metal has some relationship with the width of the lower die V of the press brake die.

Through a large number of experiments in sheet metal processing, it is found that the width of the lower die groove of the press brake die has a certain relationship with the bending radius. For example: 1.0mm plate is bent with a groove width of 8mm, so that the bending radius that is pressed out is R1 in an ideal state.

If the groove width of 20 mm is used for press brake, since the upper die moves downward during bending, the depth of the stretched sheet plate reaches a certain angle. Then we know that the area of a 20 mm wide groove is larger than that of an 8 mm wide groove. When bending with a 20 mm wide groove, the stretched area will also increase and the R angle will also increase.

Therefore, under the condition that the bending radius of the sheet plate is required, and the tool of the bending machine is not damaged, we try to use narrow grooves to bend. Under normal circumstances, it is recommended to operate according to the ratio of standard plate thickness to groove width of 1:8. The minimum should not be less than the ratio of plate thickness to groove width of 1:6, and the sheet metal bending can be appropriately smaller, and it can not be less than the ratio of plate thickness to groove width of 1:4. Recommendation: When the strength permits, the method of first grooving and bending is preferred to make a small sheet metal bending radius.

The bending radius of sheet metal processing is related to the thickness of the material and the width of the bending notch.

The simple and convenient method is:

Generally, when the plate thickness is not greater than 6mm, the bending radius of the plate can be directly used as the radius during bending. When the plate thickness is greater than 6mm and less than 12mm, the bending radius of the plate is generally 1.25 to 1.5 times of the plate thickness. When the thickness is not less than 12mm, the bending radius in the plate is generally 2 to 3 times the plate thickness.

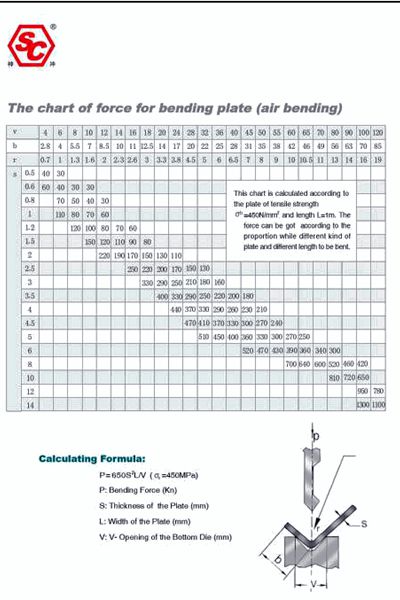

The following figure is the corresponding table of bending radius, pressure and minimum bending height provided by the press brake manufacturer.

Notes:

V: Bending notch width

R: Bending radius

B: Minimum bending height

S: Sheet thickness

The above description is the pressure parameters and the width of the bending notch of the bending machine. The actual application is calculated and used according to the pressure of the bending machine and the bending notch of your own sheet metal processing plant.