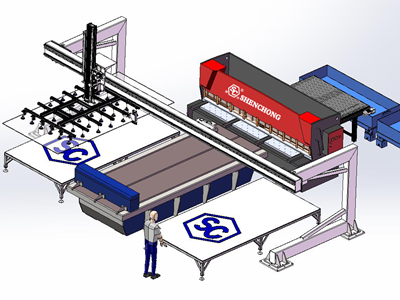

Front-feed shearing machine truss loading enable faster, more accurate, and less labor-intensive shearing. Gantry loading combined with front-feed servo positioning achieves the highest precision in high-speed shearing. No human contact with the large sheet metal and complete process isolation make shearing faster and safer. Intelligent loading drives precise shearing, making it the standard for automation in sheet metal factories.

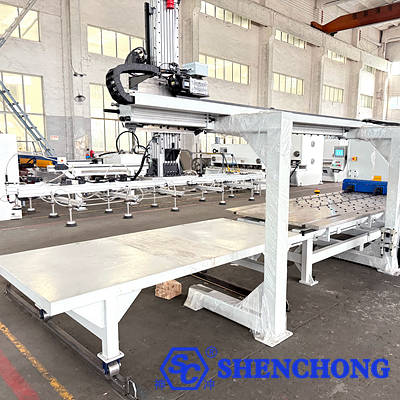

Composed of high-strength aluminum beams or steel trusses, covering a large area in front of the shearing machine. Equipped with servo motors, guide rails, and lead screws to achieve high-speed, accurate three-axis positioning and movement. Flexible and compatible with various sheet sizes.

Standard configuration includes a vacuum suction cup array, which can be adjusted to accommodate different sizes and thicknesses.

Alternatively, a mechanical clamping method can be configured for thick plates and oily sheets. Anti-deformation, oil-resistant, and stable adsorption.

Stores whole packages or single sheets of sheet material. Can be configured with an automatic sheet separation device (air blowing + vibration + magnetic separation) to avoid double sheet suction.

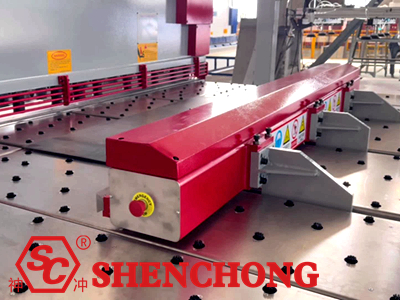

Composed of automatic positioning blocks and auxiliary pressing devices. Ensures precise positioning of the sheet material before it enters the shearing machine. Linked with the CNC system to achieve automatic feeding length control.

Can be paired with a front-feed guillotine shearing machine.

Communicates with the gantry system to achieve automatic shearing cycles.

Integrated control interface, synchronized with gantry/feeding/shearing. Supports MES system integration, job statistics, and automatic production scheduling generation.

Feeding: The gantry gripper head picks up (or clamps) a single sheet of sheet metal from the loading table.

Centering and Positioning: The sheet metal is moved to the front feeding and positioning device of the shearing machine, and its position is automatically corrected.

Front Feeding: The sheet metal is fed into the shearing machine according to the set length, achieving automatic feeding.

Shearing: The shearing machine completes the shearing action.

Repeated Feeding: The gantry continues to move and advance the sheet metal, performing cyclic shearing.

Unloading (Optional): The sheared sheet metal is automatically dropped or collected by a robotic arm/conveyor belt.

Utilizing a servo roller or gear-type front feeding mechanism, it achieves fixed-length, high-repeatability forward feeding of sheet metal.

Automatic feeding length control allows for closed-loop signal linkage with the shearing machine's PLC.

Supports single-segment, multi-segment, and continuous feeding to meet various shearing and layout requirements.

The truss adopts a lightweight aluminum beam or steel structure, paired with a servo-driven multi-axis module. It operates smoothly and is easy to maintain.

The suction cup gripping method is adaptable to various sheet materials (carbon steel, stainless steel, aluminum).

Automatic sheet separation function prevents multiple sheets from being picked up.

The entire process of loading, positioning, shearing, and unloading is automated, realizing an integrated workstation for "loading-feeding-shearing".

High-speed synchronization and safety interlocking are achieved through bus communication.

Automated truss feeding replaces manual handling, saving an average of 1-2 workers.

Front feeding is faster than traditional backgauge methods, resulting in a faster continuous shearing cycle and increasing capacity by 20%-40%.

The matching of feeding, conveying, and shearing cycles minimizes waiting time.

Front feeding uses servo closed-loop control, achieving a length accuracy of ±0.2-0.5 mm.

The sheet material remains straight during forward movement, minimizing sway, making it particularly suitable for long, thin, and high-precision shearing.

The entire process from feeding to shearing is fully automated; operators only need to monitor the system.

Effectively reduces manual labor intensity—especially advantageous when handling large sheet materials (e.g., 4×8 ft, 5×10 ft) which are difficult to handle.

Stable production, independent of human skill level.

The flexible contact of the truss suction cups prevents scratches on material surfaces, making it more suitable for high-value materials such as stainless steel, mirror panels, and aluminum sheets.

During the front feeding process, the sheet material does not repeatedly rub against the table surface, reducing scratches.

Multiple models are available, including guillotine shearing machines and front-feed shearing machines.

The loading truss can be customized according to customer sheet material dimensions (e.g., 1250mm, 1500mm, 2000mm, 2500mm width).

It can be extended and linked with a material storage system to achieve fully intelligent processing from warehousing to loading to shearing to automatic sorting.

A fully enclosed safety interlocking area reduces the risk of manual access to the shearing area.

Automatic sheet material arrival detection, anti-collision, and anti-drop protection.

The human-machine separation design makes the entire production process safer and more controllable.

- Large-volume sheet metal shearing production lines

- Sheet metal processing plants, chassis and cabinet factories

- Batch shearing of automotive parts and home appliance parts

- Steel plate processing enterprises requiring continuous fixed-length shearing

- Building unmanned production workshops in conjunction with material storage

Three Core Selling Points of Front-Feed Shearing Machine Truss Loading:

① Faster Speed - Fully Automatic Loading and Positioning, Cycle Time Increased by 50%–120%

Automatic truss loading + front servo feeding enables continuous shearing. Eliminates manual handling and pushing time, doubling production efficiency.

② Higher Precision - Servo Front Feeding Positioning ±0.1~0.2mm

Each sheet is automatically and accurately positioned, completely avoiding human error, resulting in better consistency in finished product dimensions.

③ Less Labor and Safer - Automatic Large Plate Grabbing, No One Enters Danger Zone

Heavy and large plates are automatically picked up and loaded, eliminating the need for personnel to approach the shearing area, reducing labor by 70%+, while significantly improving safety.