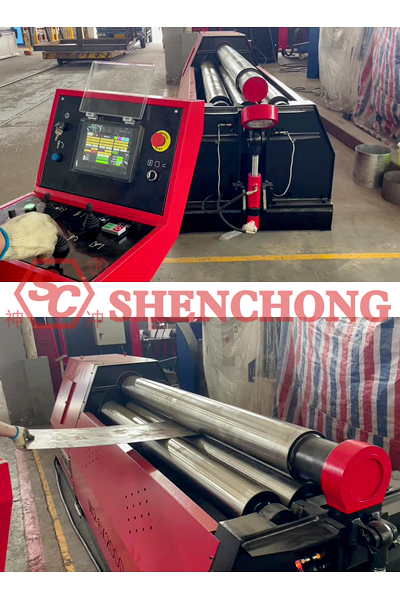

Plate roller bending machine is a forming device that uses the relative motion of rollers to cause continuous plastic deformation of metal sheets, thereby forming cylindrical, conical, or arc-shaped work pieces. This content covers structural principles → operating procedures → parameter control → maintenance → fault diagnosis → safety regulations → management suggestions, and is applicable to three-roll/four-roll sheet metal rolling machines (W11/W12 series).

Sheet metal rolling machines (plate rolling machines) are forming equipment that uses the relative motion of rollers to cause continuous plastic deformation of metal sheets, thereby forming cylindrical, conical, or arc-shaped workpieces.

Typical Application Industries:

- Sheet metal processing

- Pressure vessels

- Wind power/energy storage

- Machinery manufacturing

- Stainless steel products

- Chemical equipment

Types | Structural Features | Applicable Scenarios |

Three-roll symmetrical type | Upper roller fixed, lower roller movable | Simple structure, low cost |

Three-roll asymmetrical type | Lower roller offset | Good pre-bending capability |

Four-roll type | Upper and lower rollers + side rollers | High precision, preferred for automation |

High precision and high efficiency: Four-roll plate bending machine recommended.

- Upper Roll: Main drive roll, providing winding power

- Lower Roll: Auxiliary clamping and driving

- Side Rolls (Four Rolls): Pre-bending and forming control

- Frame: Integral load-bearing structure

- Hydraulic System: Roller lifting and pressurization

- Transmission System: Motor, reducer, gears

- Electrical Control System: Buttons / PLC / CNC

- Lubrication System: Bearing and slider protection

- Lower roll rises to clamp the sheet metal

- Side rolls rise to achieve pre-bending

- Upper and lower rolls rotate to complete winding

- Multiple cycles gradually form the sheet metal

- Adjusting the side rolls completes rounding.

- Material (Q235 / Q355 / SUS304 / Aluminum)

- Thickness

- Width

- Yield Strength

- Target Diameter

- Roundness Requirement

- Allowable Straight Edge Length

Actual Rolling Thickness ≤ Rated Thickness × 0.85 (Recommended Value)

- Hydraulic oil level ≥ 2/3 of the gauge

- No abnormal noise, no leakage

- Emergency stop, limit switches, and travel switches are normal.

- Align the centerline of the sheet material with the center of the roller shaft

- The edge of the sheet material is parallel to the roller shaft

- Wide sheets must use brackets or auxiliary supports.

- Four-roll:

One side roller rises → Pre-bend the first end

Turning direction → Pre-bend the second end

- Key Technical Points:

The amount of pre-bending determines the straight edge length

Insufficient pre-bending is the root cause of "straight edge length".

- Upper and lower rollers rotate

- Side rollers are fine-tuned in stages

- Multiple reciprocating rolling operations

- Each pressure increment ≤ 1–2 mm

- Do not press to the bottom all at once.

- Reduce the rotation speed

- Fine-tuning the side rollers

- Continuously roll 2-3 times

- Observe the change in roundness

- Completely release the hydraulic pressure

- Open the tilting mechanism (if applicable)

- Smoothly unload the work piece.

Item | Control Principles |

Feed | Small feed rate, multiple cycles |

Speed | Low speed for thick plates, medium speed for thin plates |

Pressure | Uniform and symmetrical feed rate |

Pre-bending | Approximately close to the forming radius |

- Clean roller surface and machine body

- Check hydraulic lines

- Wipe guide rails and lubricate

- Check buttons, foot pedal, and emergency stop

- Check bolt tightness

- Check lubrication supply to lubrication points

- Check reducer operating sound

Item | Contents |

Hydraulic oil | Color, bubbles, temperature |

Filter element | Cleaning or replacement |

Gear chain | Lubrication and wear |

Electrical cabinet | Dust removal |

Project | Contents |

Hydraulic System | Check oil quality, oil temperature, and filter element |

Lubrication System | Add grease to bearings and sliders |

Transmission System | Inspect chain, gears, and reducer |

Electrical System | Inspect wiring, grounding, and control cabinet. |

Roller | Inspect wear and run out |

- Replace hydraulic oil

- Comprehensive bearing inspection

- Check roller parallelism

- Check frame deformation

- Recommended oil: 46# anti-wear hydraulic oil

- Initial oil change: 3 months / 500 hours

- Subsequent oil changes: 12 months / 2000 hours

- Recommended oil temperature ≤ 55℃

- Prohibit prolonged high-speed operation under no-load

- Polish minor scratches on the roller surface promptly

- Stop machine immediately and inspect for any abnormal vibration or response

Faults | Causes | Solution |

Out of round roll | Insufficient pre-bending | Increase pre-bending |

Surface scratches | Foreign objects on the roller surface | Cleaning/polishing |

Slippage | Insufficient pressure | Pressure |

Weak hydraulic pressure | Dirty oil/leakage | Oil change/inspection |

Abnormal noise | Bearing wear | Replacement during downtime |

- Overload

- Reach hands between rollers

- Reverse emergency stop

- Striking between rollers

- Two people must operate large work pieces

- Wear protective gloves and shoes

- Stop the machine immediately in case of any abnormality