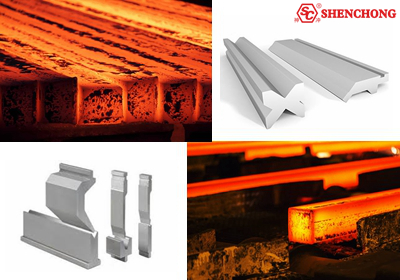

The press brake tool and die are used to bend and form sheet metal to different shapes, which is composed of different materials. All bending tools need to be heat treated, and different materials have different heat treatment methods.

Press brake tool die heat treatment is the process of annealing, normalizing and quenching.

Usually we use box furnaces and pit furnaces. Box furnaces are more popular, which the process is: we heat the furnace to a predetermined temperature firstly. Then put the workpiece into the furnace. After waiting for a period of time, it will reach the predetermined temperature, hold it for a period of time; at last we take out the workpiece, or cool it in the furnace.

We usually use the pit furnace as a carburizing treatment equipment. It is buried in the ground. After the workpiece is put in, we seal, and drip some carbon-rich liquids, such as kerosene or methanol, into the furnace, then these liquids are decomposed to carbon atoms at high temperature, which will penetrate into the surface of the workpiece.

Simply test the surface hardness. Accurate break inspection: test the depth of hardened layer, core hardness, quenched metallographic structure grade, quenched and tempered metallographic structure grade. The critical hardness value of hardened layer depth = the minimum value of quenching hardness X0.8.

The press brake die steel heat treatment exceeding the specified temperature, the grains of steel will grow up, and the mechanical properties to deteriorate, such as increased brittleness, decreased toughness, easy deformation and cracking, etc. So controlling the heating treatment temperature is very important, which will avoid overburning.

When the hot die steel is heated beyond the solid and liquidus temperature range, the chemical composition of the austenite grain boundary will change, and the local or whole grain boundary will be sintered. At this time, S, P and other compounds will be enriched on the grain boundary, it will decrease the bonding force of the grain boundary, and mechanical properties of steel deteriorate. After overburning, the steel cannot be remedied by heat treatment.

If the heat and unheat treated press brake dies are mixed, how can we tell which ones are heat treated?

Generally, the heat and unheat treated workpiece are all shot blasted, so we can not distinguish them from the color. The hardness both between 35-45, it means they can not be distinguished by the hardness either. The unheat treated (Castings), the heat treated which process through quenching and tempering, the two kinds workpiece have different metallographic structures and internal friction, so we can distinguish them from the percussion sound.

The quenching temperature is 1100 ℃, and it should be cooled in oil?

We can do metallographic analysis, to see if there is decarburization on the surface of the material. Cracks are generally caused by decarburization. Usually material H13 is used for making extrusion mold , the material hardness requirement is not very high. It is best to use the vacuum furnace, the recommended temperature is 1030~1050℃.

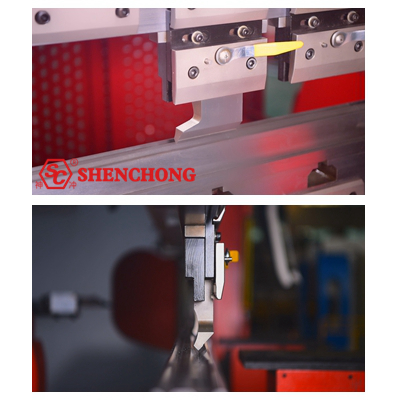

Heating and quenching at 1050~1100℃, oil quenching, can achieve the hardness of 58℃, but generally do not require such high hardness, the press brake tooling at such high hardness, performance will be very poor, easy to damage, usually HRC46~50 the bending tools made of H13 steel have good performance and durable.

1) Whether the cooling medium is cooled too fast (can not use salt water, water agent, etc.).

2) Before quenching, it may not be annealed well, resulting in excessive internal stress.

3) The metallurgy of the material is not good (non-metallic inclusions, banded structure, eutectic carbide).

4) During quenching, the furnace temperature rises too fast.

5) No tempering in time.

Know more about Press Brake Machine

High hardness, high wear resistance and high toughness, optimized treatment: 980~1200 ℃ heating and quenching, oil quenching (engine oil) 400 ℃ tempering once, 240 ℃ tempering once, HRC57~61, super durable and not chipping.

After heat treatment, the mold broken during use, which affect the press brake tool and die serive life.

Causes:

1) The material of press bending punch and die is confused, the actual quenching temperature is much lower than the quenching temperature of the required (for example, GCr15 steel is regarded as 3Cr2W8V steel).

2) The material is not properly spheroidized before quenching, the spheroidization structure is poor.

3) The bending tool quenching heating temperature is too high, or the holding time is too long.

4) The tooling is placed improperly in the furnace, it will be overheated can in areas which close to electrodes or heating elements.

5) Some bending press tools and dies with large cross-section changes, if we choose improper quenching and heating process parameters, which will cause overheating at thin sections and sharp corners.

Precaution:

1) We should strictly inspect the material before being storage, which can prevent the material from being mixed up or placed in disorder.

2) Correct forging and spheroidizing annealing should be performed before die steel quenching, ensure a good spheroidized structure.

3) Correctly formulate CNC hydraulic press brake mold and die steel quenching and heating process specifications, strictly control heat treatment temperature and holding time.

4) Regularly test and calibrate the temperature measuring instrument, make sure the instrument work normally.

5) When the press brake tool and die heated in the furnace, we should keep the punch and die at an appropriate distance from the electrode or heating element.

To sum up: Press brake tooling and dies heat treatment methods of different materials are different. In the absence of other variable factors, the correct heat treatment method will prolong the service life.