This hydraulic shear maintenance manual applies to all types of guillotine hydraulic plate shearing machine (common models such as QC11Y/QC11K). Please refer to the specific equipment manual and on-site working conditions before proceeding.

- Ensure shearing accuracy and stability.

- Extend the lifespan of the hydraulic system and mechanical structure.

- Reduce failure rate and downtime risk.

- Ensure operational safety.

- Check if the hydraulic oil level is within the indicated range.

- Observe for leaks in the oil pipes, joints, and valve blocks.

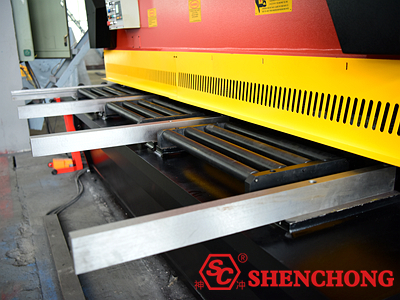

- Check if the blade fixing bolts and material clamping device are loose.

- Check if the back gauge and limit switches are sensitive.

- Pay attention to any abnormal noise or vibration during shearing.

- Observe if the pressure gauge is stable.

- Do not shear beyond specifications (thickness, material).

- Clean metal shavings from the worktable and blade edge.

- Wipe the guide rails and back gauge screw surface.

- Turn off the power and disconnect the hydraulic system.

- Check the wear of the blade edges.

- Check if the pressure cylinder returns to its normal position.

- Check the lubrication of the back gauge screw and guide rail.

- Check for loose or aged electrical wiring.

- Check the hydraulic oil temperature.

- Clean the hydraulic oil tank vent filter cap.

- Check the hydraulic oil color, for bubbles and impurities.

- Check the working status of the oil pump and relief valve.

- Verify that the blade clearance meets material requirements.

- Check the frame, slide block, and connecting rod for abnormal wear.

- Tighten critical bolts (tool holder, main cylinder seat).

- Replenish lubrication to the guide rails, lead screw, and shaft pins.

- Use the specified type of lubricating oil/grease.

- Replace or clean the hydraulic oil filter element.

- Calibrate the back gauge positioning accuracy.

- Check the limit switches and light curtains (if present).

- Check for aging of cylinder seals.

- Replace the hydraulic oil (according to the manufacturer's specified model).

- Comprehensively check the hydraulic valve assembly and pump efficiency.

- Inspect or flip the cutting tools (replace if necessary).

- Check the electrical control system and CNC system parameter backups.

- Keep the cutting edge clean and prevent impacts.

- Regularly check the cutting tool clearance and parallelism.

- Turn or regrind the cutting tool promptly after dulling.

- Changing cutting tools must be done in pairs and symmetrically.

Fault | Cause | Quick Check | Troubleshooting |

Large shear burrs | Blade dulling; excessive/uneven clearance; high material hardness | Observe the cut; measure the gap | Adjust blade clearance; flip or re-sharpen blades; match material parameters |

Crooked shear cut | Poor parallelism of upper and lower blades; loose tool holder | Observe the shearing process without load; check the fasteners | Correct parallelism; tighten tool holder and guide components |

Insufficient material clamping | Insufficient pressure in the pressure cylinder; aging seals | Observe the material clamping action; measure the pressure | Inspect seals; adjust pressure; clean valve assembly |

Slow or no return stroke | Stuck valve core; oil contamination | Listen to the valve sound; observe the oil color | Clean valve assembly; replace filter element/hydrant |

System overheating | Poor oil quality; overflow valve constantly open; excessive load | Measure the oil temperature | Change hydraulic fluid; adjust overflow valve; avoid over-specification shearing |

High oil pump noise | Insufficient oil suction; air intake; improper oil viscosity | Check the oil level and pipelines | Add oil and vent; change to appropriate viscosity oil |

Inaccurate back gauge positioning | Wearing lead screw; encoder/switch malfunction | Perform a jog test | Lubricate or replace lead screw; calibrate/replace components |

Incomplete stroke | Limit switch misalignment; parameter drift | Check the switch position | Reposition stroke; parameter calibration |

Oil leakage | Loose connectors; aging seals | Visual inspection | Tighten joints; replace seals |

Electrical malfunction | Loose wiring; interference | Roller wire inspection | Tighten wiring; tidy grounding and wiring routing |

- Regular hydraulic shear maintenance maintains blade sharpness and proper clearance.

- Prevents large burrs and skewing caused by guide rail and blade holder wear.

- Ensuring accurate back gauge positioning and improving dimensional consistency.

Result: Stable shearing quality and significantly reduced rework rate.

- Clean hydraulic oil reduces wear on oil pumps, valve groups, and cylinders.

- Timely lubrication prevents premature damage to guide rails and pins.

- Preventative maintenance is more effective than reactive repair.

Result: Lifespan of key components extended by over 30%.

- Most failures stem from oil contamination, loose fasteners, and insufficient lubrication.

- Daily and periodic maintenance allows for early detection of potential problems.

- Avoids sudden downtime affecting production plans.

Result: More continuous production and more controllable delivery times.

- Inadequate maintenance can easily lead to material clamping failure, malfunctions, and oil leaks. - Regularly inspecting electrical and hydraulic systems reduces safety risks.

- Complies with workshop safety and shear machine management regulations.

Result: Reduced workplace injuries and equipment accidents.

Project | No maintenance | Standard maintenance |

Instrument replacement frequency | High | Low |

Hydraulic component damage | Prone to occurrence | Significantly reduced |

Downtime maintenance | Passive | Planned |

Total cost | High | Low |

Result: The average annual maintenance cost per unit of equipment decreased significantly.

Common Problems | Root Causes | Relevance | After-sales professional advice |

Large burrs at the shear cut | Blade dulling/clearance misalignment | Highly Relevant | Adjust clearance and establish blade inspection cycles |

Equipment overheating | Oil contamination/relief valve malfunction | Highly Relevant | Regularly change oil and clean valve assemblies |

Unstable material clamping | Seal aging/insufficient oil pressure | Relevant | Inspect seals every six months |

Inaccurate back gauge | Lead screw wear/lack of lubrication | Relevant | Enhance lubrication and precision calibration |

Oil pump noise | Poor oil suction/improper oil | Relevant | Use specified oils and inspect oil lines |

Frequent shutdowns | Lack of preventative maintenance | Core Factors | Establish a point inspection and record-keeping system |

Standardized maintenance = stable accuracy + fewer malfunctions + lower cost

- Check oil level, blades, and operation.

- Oil level should be normal with no leakage.

- Blades should not be loose when pressing material.

- Back gauge should run smoothly.

- No unusual noises, vibrations, or odors.

- Shearing sound should be uniform.

- Hydraulic shearing machine should run smoothly.

- Hydraulic system should not overheat.

- No cutting excessively thick or hard materials.

- No cutting materials with malfunctions.

- Do not exceed the equipment's rated thickness.

- Do not cut unknown materials.

- Immediately stop the hydraulic shear machine and report any abnormalities.

- Clean metal filings, clean blade edges, clean the worktable.

- Clean metal filings from the worktable.

- Wipe the blade edges and guide rails clean.

- Reset the hydraulic shears and disconnect the power.