When manufacturers purchase a bending follow-up device, they are essentially selecting a long-term supply chain partner. They must transcend the misconception of focusing solely on unit price and instead comprehensively evaluate the four key dimensions of cost, compatibility, stability, and collaboration.

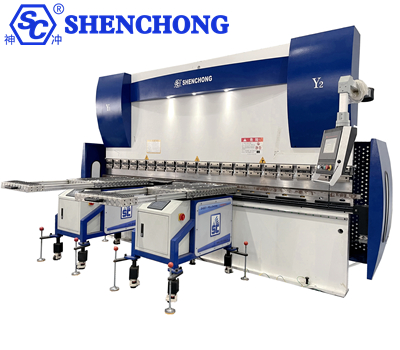

A press brake bending follower (also known as a bending machine follow-up support device or bending auxiliary support system) is an auxiliary device installed in front of a CNC press brake to support large or heavy workpieces. It automatically follows the workpiece angle during the bending process, reducing manual workpiece support and improving bending accuracy and safety.

For sheet metal equipment manufacturers and large sheet metal processing companies (with multiple bending lines), purchasing a bending follower is not just a single piece of equipment selection. it is a systematic decision involving batch cost control, line compatibility, and long-term supply chain stability. Unlike the "single unit trial" needs of small and medium-sized customers, manufacturers' procurement needs must focus on the three core objectives of cost reduction and efficiency improvement, collaborative adaptation, and risk control. The following is a breakdown of key points from the entire procurement process.

A bending sheet follower (also known as a bending auxiliary support device or a bending machine follower support device) is an auxiliary device used with CNC press brakes. It supports, follows, and positions large or heavy plates during the bending process, reducing operator workload and improving bending accuracy and safety.

- Sheet Support: Supports large plates during the bending process to prevent them from falling or being scratched.

- Automatic Follower: Raises and lowers in sync with the bending angle using a servo or pneumatic system.

- Angle Compensation: Maintains synchronized movement between the support surface and the workpiece at varying bending angles.

- Positioning Assist: Some models can also serve as a front positioner to assist with precise bending.

- Automatic Balancing: High-end models feature an electronic follower and balancing system for improved accuracy.

Item | Description | Recommendations |

Load Capacity | Select by maximum workpiece weight, generally ranging from 100kg to 600kg. | Leave a 20% margin |

Material Support Range | Depending on sheet size and press brake length. | Match the width of the press brake table |

Follow-up Mode | Electric servo / pneumatic / manual | Servo-operated models offer the most precision. pneumatic models offer the best cost-effectiveness |

Linkage Mode | Independent control / linked to press brake | CNC-linked models offer a high degree of automation |

Height Adjustment | Manual screw / electric lift | Electric adjustment is more convenient and suitable for frequent switching |

Supporting Table | Ball, nylon wheel, or felt pad | Select a scratch-resistant model depending on the workpiece surface material |

Synchronous Control | PLC / press brake interface / photoelectric sensor | Automatic synchronous control is recommended |

Protective Design | Limit protection, emergency stop, finger pinch protection | Ensures operational safety |

Compatibility | Compatible with press brake interfaces of different brands | Optional modular universal interface |

- Press Brake Model and Tonnage (to confirm interface compatibility)

- Maximum Workpiece Size and Weight

- Bending Angle Range (to confirm tracking trajectory)

- Working Environment and Power Supply (AC220V/380V)

- Need for Interoperability with the Press Brake CNC Control System

- Bending Follow-up Device Manufacturer After-Sales Support and Warranty Period

- Communication Test with Press Brake: Verify that the tracking angle is synchronized with the CNC system.

- Load Test: Continuous operation for one hour at rated load without any sticking or abnormal noise.

- Safety Limit and Anti-Pinch Test: Emergency stop and limit protection should be provided.

- Control Panel Inspection: Ensure that the buttons, touch screen, and angle display are accurate.

- Document Delivery: Must include electrical schematics, operating instructions, and maintenance manuals.

When selecting a sheet follower manufacturer, focus on the following aspects:

- Technical Strength: Experience with press brake system integration (e.g., Delem/ESA/Cybelec protocol adaptation)

- Application Cases: Successful customer applications in sheet metal automation production lines

- Structural Design: Frame welding accuracy, surface treatment, and anti-tilt design

- After-Sales Service: On-site installation, commissioning, and control system training are available

- Spare Parts and Consumable Parts: Are standard replacement parts available for rollers, guide rails, motors, etc.?

- Brand Reputation: Domestic and international customer reviews and exhibition presence

These suppliers lack their own factories and rely solely on outsourced assembly. These risks include:

- Uncontrollable delivery cycles for bulk orders (depending on upstream OEMs).

- Unidentified sources for core components, resulting in a lack of spare parts availability for later repairs.

- Lack of technical R&D capabilities, resulting in an inability to provide customization and system integration services.

How to avoid pitfalls:

Request the production base address and production license, and verify whether the "Goods Name" on the VAT invoice contains the word "manufacturer" (trader invoices often include "wholesale" or "retail").

Some suppliers attract bulk orders by offering prices "30% below market price," but they:

- Cut corners (e.g., using ordinary steel instead of high-strength steel, or inflating load capacity).

- Lack of after-sales service (they shirk responsibility during the warranty period, forcing the manufacturer to cover repair costs).

- Lack of upgrade capabilities (they are unable to provide trolley modification services when the manufacturer upgrades its production line).

How to avoid pitfalls:

Purchase one or two trial units first, testing them for three months (focusing on verifying positioning accuracy, stability, and load capacity), before signing a bulk contract. Include a clear "quality spot check" clause in the contract (30% of the bulk goods will be randomly inspected upon arrival. if unsatisfactory, the entire batch will be returned).

If a manufacturer requires a follower device to integrate with an existing production line (such as a press brake or loading and unloading robot), these suppliers can only provide standalone carts and are unable to achieve system integration. This results in:

- Inability to synchronize equipment, which reduces production efficiency.

- The need to hire a third-party team for debugging, increasing costs.

- Fragmented data monitoring and subsequent management become impossible.

How to avoid this pitfall:

Before purchasing, ask the supplier to provide a "similar case study" (e.g., integrating 10 carts with the MES system for an automotive sheet metal factory) and provide an on-site demonstration of the system integration results.

Although a press brake bending follower is an auxiliary device, it plays a significant role in improving production efficiency, reducing labor costs, and enhancing bending quality.

Prioritize the following when purchasing:

- Compatibility (with the press brake system)

- Stability (mechanical and servo systems)

- Service guarantee (commissioning and after-sales service)

Purchasing recommendations:

- Clearly determine the workpiece weight and dimensions → select a load capacity range

- Confirm the press brake interface and linkage method

- Prioritize servo-controlled models (for higher precision and efficiency)

- Request the manufacturer to provide actual application videos and installation examples

- Pay attention to warranty and after-sales response speed