CNC laser cutting machine price is influenced by many factors. Its cost structure includes not only the purchase price of the equipment itself, but also the technical configuration, brand premium, after-sales service, and long-term operating costs.

When purchasing, companies should balance budget and performance based on their processing needs (thin/thick plate, large/small batches, and requirements for precision and efficiency). The following is a detailed analysis of laser cutting machine prices.

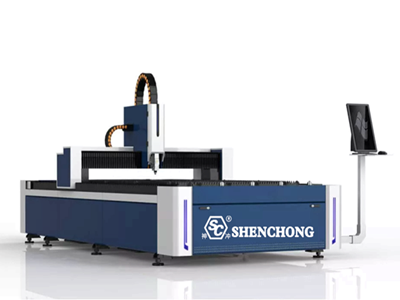

Price Range: US$6,000-20,000.

Features: Suitable for cutting thin sheets (metal thickness under 6mm), primarily used in small fabrication plants, advertising signs, sheet metal prototyping, and other applications.

Advantages: Low investment, simple operation, and relatively low energy consumption.

Price Range: US$20,000-100,000.

Features: These are the most widely used models in the market, meeting the needs of most sheet metal processing companies, and typically capable of cutting thicknesses under 25mm.

Application Industries: Automotive parts, chassis and cabinets, construction machinery, sheet metal fabrication plants, etc.

Price Range: US$130,000-400,000 or higher.

Features: Suitable for high-speed cutting of thick plates (over 40mm to 100mm), offering extremely high processing efficiency and capable of replacing some plasma or flame cutting processes.

Application Industries: Heavy Industry, Shipbuilding, Rail Transit, Energy Equipment, Steel Structure Manufacturing, etc.

The laser accounts for approximately 30% to 50% of the total machine cost.

Imported brands (such as IPG, SPI, and Trumpf) are more expensive but offer better stability and cutting accuracy. Domestic lasers (such as Raycus and Maxus) are cheaper, offer a better price-performance ratio, and have gradually matured in recent years.

The brand and performance of the cutting head directly impact cutting speed and processing quality.

High-end brands (such as Precitec, RayTools, and WSX) offer features such as autofocus, collision avoidance, and air pressure monitoring, with prices ranging from tens of thousands to over 100,000 yuan.

The CNC system determines cutting path optimization, processing accuracy, and ease of operation.

High-end systems (such as Beckhoff, Siemens, CYPCUT, and FSCUT) vary significantly in price.

The bed's manufacturing precision and stability impact the machine's lifespan and processing quality. Heavy-duty welded or cast machine beds are more expensive, but they can withstand the high-speed cutting of high-power lasers.

These include chillers, dust removal systems, gas supply (oxygen, nitrogen, air compressors), lenses, and nozzles.

The long-term cost of consumables cannot be ignored.

Manual loading and unloading: The lowest cost, suitable for small-scale processing.

Semi-automatic loading and unloading: Improves efficiency, but adds $14,000 to $28,000 in price.

Fully automated material storage and loading and unloading systems: Suitable for large-scale production, but significantly increases equipment costs by $60,000 to $200,000.

Automatic edge detection, automatic typesetting software, perforation optimization, and cutting monitoring systems.

Fume purification equipment, chillers, and auxiliary gas supply systems are also included.

The more features, the higher the price, but they can significantly improve production efficiency and processing quality.

- Energy Costs: High-power lasers consume a lot of power, so electricity costs need to be considered.

- Assist Gas Consumption: Nitrogen is often used for cutting stainless steel, while oxygen or air is used for thick plates; long-term consumption costs are high.

- Consumable Part Replacement: Lenses, nozzles, ceramic rings, etc. are common consumable parts.

- Maintenance and Downtime Costs: Inadequate maintenance can result in downtime losses.

- Small Businesses/Startups: They are more concerned with the return on investment (ROI) and tend to choose domestically produced low- to medium-power laser cutting machines.

- Medium- to large-scale sheet metal fabricators: They prioritize processing efficiency and overall cost control, choosing medium- or high-power models that balance speed and stability.

- Heavy Industry/Shipbuilding/Rail Transit Companies: They are more concerned with thick plate cutting capabilities and equipment stability, and tend to choose high-power laser cutting machines.

The laser cutting machine price is influenced by many factors, and prices vary significantly depending on the model, configuration, and application. The following is a detailed analysis, categorized by the main influencing factors:

Advantages: Excellent beam quality, high efficiency, low consumables, and simple maintenance.

Advantages: Suitable for cutting non-metallic materials (wood, acrylic, plastic), and good at cutting thick plates.

At the same power, fiber lasers are generally more expensive than CO2 lasers, but offer lower long-term operating costs.

- Fiber lasers: Currently the mainstream choice for metal cutting, they offer high efficiency, low maintenance costs, and a long lifespan. While more expensive than traditional CO2 lasers, they offer a better overall price-performance ratio.

- CO2 lasers: Suitable for cutting non-metals (wood, acrylic, fabric) and some thin metals. Initial equipment investment is low, but energy consumption and maintenance costs are higher.

- YAG solid-state lasers: Primarily used for welding and marking, with limited cutting applications, they are gradually being replaced by fiber lasers.

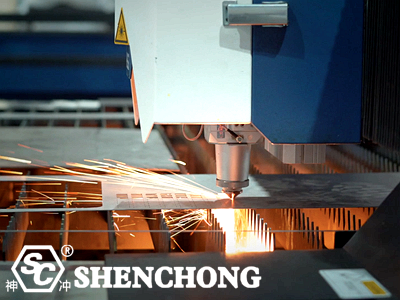

- Power directly determines cutting speed and thickness.

- Low power (≤1kW) is inexpensive and suitable for thin plates and small processing.

- High power (≥4kW) is expensive and suitable for thick plate cutting and industrial production.

- Price Growth Trend: Cost increases nonlinearly with increasing power. High-power equipment requires more precise optics and cooling systems.

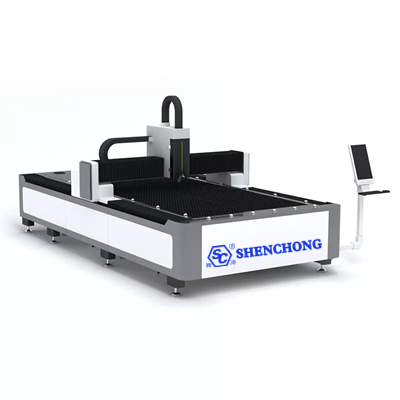

Standard Format 1500×3000mm: Most common, price benchmark.

Medium-to-large Formats 2000×4000mm and 2500×6000mm: Require a more powerful machine bed and drive, resulting in a 20-50% price increase.

Ultra-large Formats (such as the 3000×12000mm used in the shipbuilding and wind power industries): High customization is required, resulting in a significant price increase.

Gantry/Single-beam/Dual-beam/Multi-beam: The more complex the structure and the greater the rigidity, the higher the price.

High-precision structures (linear guides, ball screws) improve stability and accuracy, but are more expensive.

Ordinary welding machine bed: Low cost, but lacks stability under long-term high-power operation.

Annealed stress-relief welding machine bed: Commonly used in mid-to-high-end machines, offering excellent stability. Cast iron bed: dedicated to high-end models, good shock resistance, high cutting accuracy, and the highest cost.

- Power directly determines cutting speed and thickness.

- Low power (≤1kW) is inexpensive and suitable for thin plates and small processing.

- High power (≥4kW) is expensive and suitable for thick plate cutting and industrial production.

- Price Growth Trend: Cost increases nonlinearly with increasing power. High-power equipment requires more precise optics and cooling systems.

Made in China (Raytools, WSX): Moderately priced, commonly found in mid-range models.

International Brands (Precitec, LaserMech): More stable performance, strong autofocus and high-speed punching capabilities, but more expensive.

Made in China (Cypcut, Ospri): Comprehensive features and a high cost-performance ratio.

International Brands (Beckhoff, Fanuc, Siemens): Used in high-end models, with higher prices and higher precision.

Servo Motors (Panasonic, Yaskawa, Siemens vs. Domestic Brands): Imported motors are more expensive, but offer better precision and lifespan.

Screw Drive vs. Rack-and-Pinion Drive: Rack-and-Pinion drives are suitable for large-format production and are also more expensive.

The quality of lenses, mirrors, and reflectors directly impacts cutting results.

High-precision imported optical components are expensive.

Smoke extraction, exhaust, chillers, automatic material changers, and autofocusing devices all add to the price.

The more comprehensive the supporting systems, the higher the total price of the equipment, but they also improve efficiency and safety.

Whether to cut metal or non-metal, thick or thin plate, will influence the model selection.

Thick plates and highly reflective materials (copper and aluminum) require high-power fiber lasers and special anti-reflective optical systems, which are more expensive.

Long-term warranty, technical training, and spare parts availability are all reflected in the equipment price.

Some manufacturers offer a "whole-machine warranty + free replacement of wearing parts," which is slightly more expensive.

Customized equipment (special sizes, special functions) is significantly more expensive than standard models.

Bulk discounts are available for large orders, but the purchase price of a single unit is higher.

Power Range | Typical Power Range | Suitable cutting thickness (carbon steel/stainless steel/aluminum alloy) | Processing speed (using 6mm carbon steel as an example) | Main Application Industries | Recommended Price Range |

Low Power Model | 500W – 1.5kW | Carbon steel ≤6mm / Stainless steel ≤3mm / Aluminum ≤2mm | 8–12 m/min | Advertising Signs, Small Hardware, Crafts, Prototyping | $6,900-$20,800 |

Medium Power Model | 2kW – 6kW | Carbon steel ≤25mm / Stainless steel ≤15mm / Aluminum ≤12mm | 15–30 m/min | Sheet Metal Fabrication, Chassis and Cabinets, Automotive Parts | $27,800-$111,000 |

High Power Model | 8kW – 15kW | Carbon steel ≤45mm / Stainless steel ≤30mm / Aluminum ≤25mm | 30–60 m/min | Construction Machinery, Steel Structures, Shipbuilding, Rail Transit | $139,000-$278,000 |

Ultra-High Power Model | 20kW – 30kW+ | Carbon steel ≤100mm / Stainless steel ≤60mm / Aluminum ≤50mm | 60–120 m/min | Heavy Industry, Energy Equipment, Shipbuilding, Large-Scale Steel Processing | $278,000-$417,000+ |

These are affected by gas type (oxygen/nitrogen/air), plate quality, and equipment configuration. The parameters in the table are typical reference values.

For the same power, imported lasers (such as IPG and Trumpf) are more expensive, while domestic brands (such as Raycus and Maxphotonics) offer better value for money.

Depending on the configuration (such as the cutting head, control system, and automated loading and unloading system), the price of the entire machine can vary by 20%–40%.

Low-power models are more suitable for thin plates, advertising, and small appliance parts; medium-power models are suitable for general sheet metal processing; high-power and ultra-high-power models are primarily used for thick plate cutting and high-end manufacturing.

The main factors determining the a laser cutting machine price include power, core component configuration, brand, and after-sales service. When purchasing, consider more than just the list price. Instead, consider your processing needs, operating costs, maintenance services, and long-term returns.

Generally speaking:

- Entry-level machines are suitable for small-scale production.

- Mainstream mid-power models meet most sheet metal processing needs.

- High-power machines are suitable for large-scale production, thick plate processing, and high-end manufacturing.

The price of a laser cutting machine is influenced by many factors. Differences in model, power, and configuration can result in prices varying by several or even dozens of times. The following key factors determine the price of a laser cutting machine.

Influencing Factors | Price Impact | Description |

Laser Type | Medium-High | Fiber Optic > CO₂ |

Laser Power | High | Higher power, higher price |

Table Size | Medium-High | Large area, complex structure, high cost |

Control System | Medium | High-end system improves precision and functionality |

Optics & Auxiliary Systems | Medium | Improves cutting accuracy and efficiency |

Cutting Material & Thickness | High | Thick plates/highly reflective materials require high-end configuration |

Brand & Origin | Medium-High | Imported > Domestic |

The laser cutting machine price isn't determined by a single factor. It's the product of a combination of factors, including laser power, width, bed structure, core component configuration, degree of automation, and brand influence.

When purchasing a laser cutting machine, companies should balance budget and performance based on their processing needs (thin/thick plate, large/small batches, and precision and efficiency requirements).

- For those with limited budgets and working on sheet metal and thin plate processing: Choose a 1-3kW domestic fiber laser cutting machine for the best value.

- For those in the machinery manufacturing/automotive industry: A 6kW mid-power machine is recommended, suitable for both thin and medium-thick plate cutting.

- For those in the heavy industry (primarily thick plate processing): A high-power machine of 12kW or higher, paired with an imported cutting head, is recommended.

- For large-scale batch processing: An automated loading and unloading system with a material storage system is essential. While the initial investment is high, the efficiency is extremely high.

- For those in the advertising and non-metal industries: A CO₂ laser machine is more economical.