When purchasing a metal plate rolling machine, you need to consider various factors such as plate thickness, width, material, bending accuracy, and production efficiency. Here's a detailed guide for buying the best metal plate bending rollers .

- Light-duty: 1–6mm

- Medium-duty: 6–20mm

- Heavy-duty: 20mm and above

The rolling capacity of the machine must be greater than the maximum plate thickness. it's recommended to leave a 10–20% safety margin.

The working roll length of the plate bender must be greater than the plate width. Common lengths include 2000mm, 2500mm, 3000mm, and 4000mm.

- Mild carbon steel: Standard models are sufficient.

- High-strength alloy steel, stainless steel: You need to choose a model with higher power and stronger rollers.

- Symmetrical type: Simple structure, suitable for medium-to-thick plates, and inexpensive.

- Asymmetrical type: Allows pre-bending in one operation, suitable for thin plates, and achieves good roundness.

- Disadvantages: Requires some operator experience; efficiency is moderate.

- Can complete material feeding, pre-bending, and rolling in one operation, resulting in high efficiency and accuracy.

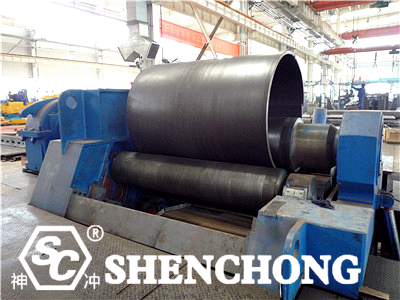

- Suitable for thick plates, large-diameter rolls, and mass production.

- Disadvantage: More expensive than three-roller machines.

- Upper roller diameter and strength: Larger diameter and higher strength mean better rigidity, ensuring accurate forming.

- Pre-bending capability: Whether it can perform end pre-bending without using an external press.

- CNC system: High-end models with programmable control offer higher repeatability and accuracy.

- Rolling roundness accuracy: High-precision machines are suitable for manufacturing pressure vessels and aerospace components.

- Hydraulic system: Stable and reliable, with overload protection to extend lifespan.

- Brand and Reputation: Choose an experienced manufacturer to ensure better product quality and reliable after-sales service.

- After-Sales Support and Spare Parts: Does the manufacturer provide timely repair services and supply spare parts such as rollers and hydraulic components?

- Installation and Training: Does the manufacturer offer installation, commissioning, and operator training?

- For thin plates and small work pieces: Asymmetrical three-roller plate bending machine – economical and practical.

- For medium-to-thick plates and general production: Universal three-roller plate bending machine with a top roller.

- For thick plates, large diameters, and high-precision requirements: Four-roller plate bending machine.

Application/Material/Requirements | Recommended Machine Types | Recommended model examples/typical parameters | Description/Applicability |

Thin sheet metal/Small diameter coils/Single piece or small batch production | Asymmetrical Three-Roll Plate Bending Machine | W11F-6×1500/W11F-8×2000 | Asymmetrical three-roller machines can effectively address pre-bending issues with thin plates, resulting in minimal straight edges. |

Thin to medium-thickness sheet metal/Requires pre-bending capability | Universal Three-Roll Plate Bending Machine with Top Roll | SW11SNC-36×5000 | They can perform pre-bending and roll forming in a single operation, suitable for processing various plate thicknesses. |

Medium-thickness sheet metal/Larger diameter/Bulk production | Symmetrical Three-Roll Plate Bending Machine | SW11-16×2500/SW11-25×3000 | Symmetrical three-roller machines have a simpler structure, but their pre-bending capability is weaker. |

High precision/Thick sheet metal with large diameter coils | SW12-60X2000/SW12-70X3000 | Four-roller machines offer better control of plate deformation and higher symmetry, making them suitable for applications with high-precision requirements. |

When reviewing specific models, pay close attention to the following parameters/indicators:

Parameters | Unit | Meaning/Requirements | Important Notes |

Maximum plate thickness | mm | Maximum plate thickness that the equipment can roll | Always leave some margin for safety; avoid overloading the equipment. |

Maximum plate width | mm | Maximum allowable plate width | The wider the material, the higher the structural strength requirements for the equipment. |

Minimum bending diameter | mm | Minimum rollable diameter under full load conditions | Pay special attention to this if you are working with small diameters. |

Bending speed | m/min or m/s | Plate rolling speed | Higher speed means higher efficiency, but also higher demands on the control system. |

Diameter of upper/lower/auxiliary rollers | mm | Key factors of roller rigidity and load-bearing capacity | Larger diameters are generally more stable and have better resistance to deformation. |

Pre-bending capability/Straight edge pre-bending | mm | Whether the plate ends can be pre-bent automatically, and the remaining straight edge length | If you require no straight edges or only minimal straight edges, choose a machine with a pre-bending function. |

Control method | Mechanical, hydraulic, digital display, CNC | Control accuracy and automation level | CNC machines are more expensive, but offer significant advantages for repetitive work and high-precision applications. |

Drive power/Motor specifications | kW | Drive capacity specifications | The driving force must be sufficient to overcome the material's elastic recovery force and frictional resistance. |

Machine structure/Reinforcement ribs/Welding structure | — | Structural stability and rigidity | The machine must have sufficient rigidity to resist bending deformation and vibration. |

Follow these steps.

- What is the maximum plate thickness to be rolled? What is the minimum diameter?

- What is the plate width?

- What is your annual production capacity/batch size/frequency of continuous operation?

- What are your requirements for roundness/accuracy/straight edge length/automation?

Use the comparison table above to determine the general type of machine you should choose (e.g., four-roller, high-end CNC, three-roller universal, etc.).

Find a model in the corresponding category that is slightly larger than your requirements as a starting point.

Share your specific needs (such as non-standard width, automatic feeding, special materials, etc.) with the equipment manufacturer to get a quote or a customized solution.

- Material to be processed: Carbon steel / Stainless steel / Aluminum alloy, etc. (Different materials have different requirements for friction, springback, and strength).

- Maximum plate thickness (mm) and common thickness range.

- Maximum plate width (mm).

- Minimum inner diameter (or minimum bending diameter/minimum R).

- Annual production volume / Need for batch production and automation (single-pass forming or multiple passes).

- Accuracy requirements (concentricity, straight edge length/allowable residual straight edge).

- Need for CNC, automatic feeding, material handling, workpiece flipping, and other automation features.

(Providing these parameters helps manufacturers provide accurate quotes and match the right machine model.)

- The machine model, roller diameter, torque, and machine rigidity should be selected based on the maximum plate thickness, width, and minimum inner diameter.

- Distinguish between three-roller and four-roller machines:

Three-roller machines are simpler, cheaper, and take up less space. Four-roller machines allow pre-bending in one pass, result in shorter straight edges, higher accuracy, and are suitable for repetitive batch production and complex workpieces.

Choose four-roller machines for efficiency, accuracy, and minimal straight edges. Consider three-roller machines for limited budgets, small workshops, or occasional thin plate bending.

- Pre-bending is crucial for final product fit (seam welding). Check if the machine can pre-bend both ends, if plate flipping is required, and if both ends can be pre-bent in one pass. Poor pre-bending can lead to inability to weld or require extensive rework.

- Roller diameter and material: Roller diameter determines the minimum bending diameter and stress distribution; roller material/hardened layer determines wear resistance and lifespan.

- Main drive power and torque: The thicker and wider the plate, the higher the required driving torque. Ask the manufacturer for the "torque/horsepower curve for the maximum bending thickness."

- Parallelism control (roller parallelism/EPS or electronic balancing): High-precision machines use electronic detection/proportional valve control for roller parallelism, affecting concentricity and straight edge length.

- CNC and programming: CNC allows saving processes, automatic positioning, and automatic pre-bending steps, reducing reliance on operator experience, suitable for batch production.

- Safety and auxiliary features: Overload protection, emergency stop, safety fencing, workpiece support, swing roller support, feed/discharge table, etc.

- Maintenance of wear parts: Check the specifications of roller bearings, gearbox type (planetary/worm gear, etc.), and hydraulic component brand; confirm the lead time and cost of spare parts.