Servo Electrical CNC Press Brake Machines use a servo motor to drive a hydraulic pump, delivering oil on demand and precisely controlling hydraulic flow and pressure. Unlike traditional hydraulic presses, which operate at high pressure, they eliminate the need for continuous operation. This results in energy savings, reduced noise, and improved precision.

In the increasingly competitive sheet metal manufacturing industry, companies are constantly seeking cutting-edge equipment that can improve efficiency, reduce costs, and enhance competitiveness. If you're looking for the best CNC press brake, an energy-efficient press brake solution, or high-precision bending equipment, a servo electrical CNC press brake is your best choice.

A hybrid servo CNC press brake is a sheet metal bending machine that integrates hydraulic and servo motor drive technology. It combines the high tonnage output of traditional hydraulic press brakes with the energy-efficient, precise control advantages of electric servo systems.

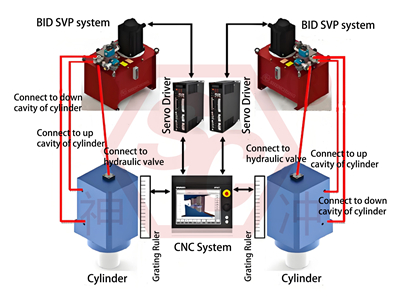

This servo CNC plate bending machine utilizes a BiD-SVP (bi-directional servo pump) system. The BiD-SVP system offers advantages such as energy efficiency, reduced idling time, and increased production efficiency, directly saving users significant costs on electricity and minimizing hydraulic oil consumption. Furthermore, it significantly reduces carbon dioxide emissions and environmental pollution.

Servo electrical CNC press brake machines are powered by a servo motor driving a hydraulic pump. The hydraulic system operates only when needed. Unlike traditional hydraulic presses that operate at continuous high pressure, it delivers oil on demand, reducing energy consumption and heat generation.

Hybrid servo electrical cnc press brake machines are characterized by energy saving, precision, low noise, and high efficiency, while also balancing large-tonnage processing capabilities with environmentally friendly requirements.

A servo motor drives the hydraulic pump, supplying oil on demand and automatically stopping the motor when not needed.

This saves 30% to 60% energy compared to traditional hydraulic press brakes.

A servo closed-loop control system achieves slide repeatability of ±0.01mm.

Bending angles are stable and consistent, making them suitable for high-precision sheet metal processing.

The motor only runs when in motion; it is silent in standby mode.

Noise levels are over 20 decibels lower than those of traditional hydraulic presses, improving the working environment.

Sensitive start and stop times ensure fast bending cycles.

Processing efficiency is approximately 20% higher than that of conventional hydraulic presses.

The oil pump operates intermittently, reducing heat generation. Longer hydraulic oil life, less wear on hydraulic components, and lower maintenance costs.

Energy saving, noise reduction, and reduced leakage align with modern green manufacturing trends.

Retaining the high tonnage capacity of hydraulic presses, it can process thick plates and large work pieces.

At the same time, it offers the advantages of servo presses for high-precision bending of medium and thin plates.

The advantages of servo electrical CNC press brakes primarily lie in their ability to combine the high tonnage of hydraulic press brakes with the energy efficiency and precision of fully electric press brakes.

A servo motor drives the hydraulic pump on demand, unlike traditional hydraulic presses that run continuously.

Energy consumption is reduced by 30% to 60%, significantly saving electricity costs over long-term use.

Servo closed-loop control enables slide repeatability of up to ±0.01mm.

Bending angle consistency is excellent, making it suitable for high-precision sheet metal processing (such as electrical cabinets and precision housings).

The motor only runs when in motion; it is silent in standby mode.

Noise levels are approximately 20 decibels lower than those of hydraulic presses, improving the workshop environment.

Fast startup and response times shorten bending cycle times.

Processing efficiency is 15% to 25% higher than traditional hydraulic press brakes.

Hydraulic oil generates less heat and has a long service life.

Fluid contamination is minimized, the hydraulic system is stable, and maintenance costs are reduced.

Retaining the large tonnage advantage of hydraulic presses, this machine can bend thick plates and large work pieces.

At the same time, it offers the high precision and energy-saving features of a fully electric press brake.

Energy-saving, low noise, and low fuel consumption align with the trend of green smart manufacturing.

Comparison Parameters | Traditional Hydraulic | Hybrid Servo | Full Electric |

Energy Consumption | High, motor runs continuously | Medium, 30%-60% energy savings | Low power, highest energy efficiency |

Accuracy | Medium, repeatability ±0.05mm | High, ±0.01mm repeatability | Extremely high, ±0.005mm repeatability |

Noise | High, motor runs continuously | Low, silent standby mode | Low power, virtually silent |

Efficiency | Normal, slow cycle | High, fast response | High power, fastest cycle |

Maintenance Cost | High, high oil temperature and high fuel consumption | Medium, long oil life | Low power, no hydraulic system |

Equipment Lifespan | Medium, hydraulic components are prone to wear | High, low oil temperature and minimal wear | High power, easy maintenance |

Tonnage Range | Large, suitable for thick plates and heavy work pieces | Large, retains hydraulic advantages | Small to medium size, commonly used for thin plates |

Price | Relatively low | Medium | High |

Application Scenarios | Thick plates, large work pieces, and limited budgets | Suitable for medium and heavy plate applications, pursuing energy savings and precision | Thin plates, high precision, small batch production |

- Traditional hydraulic press brakes: Suitable for large tonnage, thick plates, and limited budgets.

- Hybrid servo press brakes: A compromise, offering a balance of energy efficiency, precision, and efficiency, suitable for most sheet metal fabricators.

- Fully electric press brakes: Suitable for thin plates, small work pieces, and industries requiring extremely high precision (such as 3C and precision sheet metal).

Servo Electrical CNC press brake machines combine the power of hydraulic presses with the energy efficiency and precision of servo presses, offering a highly efficient solution between traditional hydraulic and fully electric press brakes. Hybrid CNC press brakes offer advantages such as energy saving, precision and efficiency, low noise, minimal maintenance, and a wide range of applications, providing a balanced solution between hydraulic and fully electric press brakes.

With their exceptional energy efficiency, top-tier precision and efficiency, excellent return on investment, stable performance, and advanced intelligence, hybrid servo CNC press brakes have become the preferred equipment for transformation and upgrading in the sheet metal fabrication industry. It is not just a machine, but also a strategic investment for enterprises to enhance their core competitiveness, reduce costs and increase efficiency, and move towards green and intelligent manufacturing.