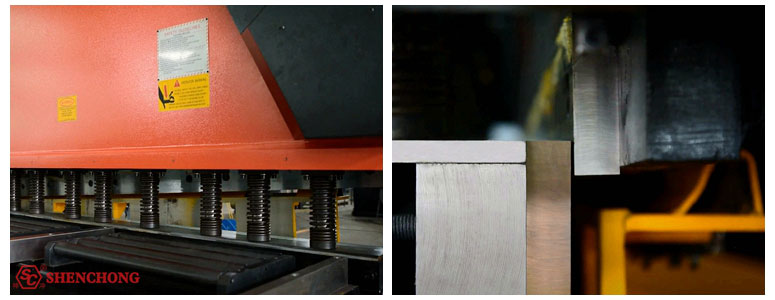

The blade of guillotine shear is consumable. We need to do regular maintenance, including cleaning, grinding and replacement of blades.

The cleaning is indispensable and must be maintained. The unpainted parts should be regularly coated with anti-rust grease.

The service life of the shears can be used for more than ten years. But the life of the blade is not that long. When the blade is dull, we need to grind the blade.

Next, we will teach you how to grind blade.

Through grinding and maintenance, the blades of hydraulic shears can well maintain their basic performance. At the same time, the work piece cutting will be more powerful to ensure the smooth progress of the process.

– Starting from the blade plane, make sure that the blade is bright and free of blunt objects.

– Then grind the sides and pay attention to parallelism.

– If you find that the grinding surface is inclined, you can change the grinding pressure. In addition, apply appropriate force on the thicker side.

– Pay attention to check the accuracy and calibration of the grinding blade.

– High temperature will affect the accuracy of the blades. When sharpening the blade, the temperature of the steel blade should not exceed 50 degrees. If the temperature is too high, please cool down for a while before continuing.

– Finally, after grinding, apply a layer of anti-rust liquid to avoid rust.

Although we can sharpen the blade to make it possible to continue using it after blunt. But the blade of the shears usually can only be polished 1-3 times. When polishing more than 5 times, must replacing sheet metal shear blades.

Then, we will tell you how to replace the blade.

– Start the machine, adjust the shearing angle, and adjust the blade gap to the maximum value.

– After waiting for the hydraulic shears to run up and down for several rounds, turn off the machine tool and disconnect the main power supply the machine.

– Disassemble the protective fence of the hydraulic shears, the hold-down cylinders (note that there is hydraulic oil overflow) and the blades base cover.

– Disassemble the lower blade of first:

Loosen all the mounting screws of the lower blade, and use a long square wooden to firmly press the lower blade against the back of the machine tool to prevent the lower blade from tipping backwards or slipping off.

Remove the screws on the lower blade, and then pull out the lower blade from the side of the hydraulic shear.

– Then disassemble the upper blade:

Loosen all the mounting screws of the upper blade.

Insert two suitable square wooden between the workbench and the upper blade.

– Tighten the upper blade firmly, remove the screws on the upper blade. And then slowly loosen the wooden square while pulling out the upper blade from the side of the hydraulic shear machine.

– After removing the blade, clean it piece by piece. All four sides of the blade can be used. Choose the good side for installation.

– Check straightness in both horizontal and vertical directions.

The blade grinding and changing operations require professionals. As a professional shearing machine manufacturer, Wuxi Shenchong company has a complete after-sales service and technical team.

For the convenience of users, we can provide users with the greatest technical support. You can also invite us to debug and repair metal shears or blades. Or, we can guide the user to grind and replace the blade.

Wuxi Shenchong company also provides customers with custom sheet metal shear blades services. If you have any needs, please contact us.