When purchasing plate shears, many users will specially ask about the accuracy. Therefore, the accuracy performance of plate shears has been the focus of continuous research and improvement for manufacturers.

High precision CNC sheet metal guillotine shearing machine is Shenchong characteristic product. We will analyze the affecting factors and improvement measures for you.

With the continuous improvement of the quality requirements of plate shears, it is necessary for users to fully understand the actual processing accuracy and the main factors affecting the cutting accuracy, so as to take corresponding measures to improve the cutting quality.

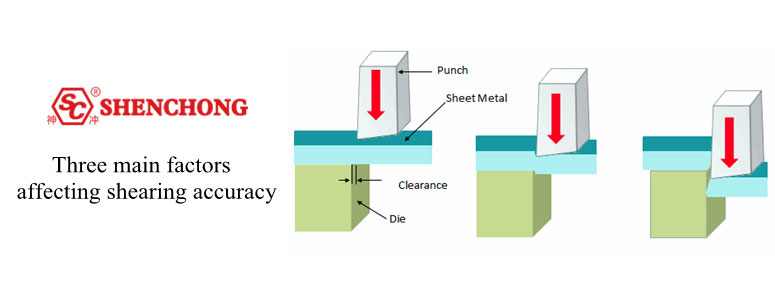

There are 3 main factors affecting the accuracy of plate cutting: sheet metal, equipment, processing and operation.

Different plate shearing requires different types and configuration of shearing machine and different material blades. The thickness, hardness, smoothness and other properties of the plate will affect the shear accuracy.

The nature of the plate is closely related to the material of the blade used by the guillotine shear. If we don’t know all the information about the plate and equip the shearing machine with an inappropriate cutting blade, the accuracy will be greatly reduced. Not only the processed products are not qualified, but also blade damage and machine equipment damage.

If you need high-precision processing, please buy a high-precision plate shearing machine for sale. Do not choose low-end shears, such as: manual shear, mechanical shear, swing beam shear, etc.

When you have purchased a suitable equipment, the next step is to check and make sure the equipment is running smoothly.

You need to check the guillotine metal shears from the following aspects:

– Blade material

Composition, hardness, toughness, wear resistance, corrosion resistance

– Machine manufacturing process

Forging, quenching, tempering, grinding

– Positioning accuracy and reliability of back gauge

The back gauge of plate shears directly affects the dimensional accuracy of accessories loading.

Especially for large and thick plates, the impact will be difficult to avoid.

Therefore, good stiffness and strength are required for the rear stopper. In the production, the manufacturer needs to check the deformation degree and normal operation to ensure its parallelism with the blade and the accuracy of adjustment. Avoid cutting out the plate beyond the size error range, and the plate with one end big and one end small.

– The clearance of the eccentric sleeve of the tool hold

Make sure the blade is installed accurately. If it is too large, the adjusted blade clearance will not be maintained. Or, the tool rest is damaged or deformed.

– Tool holder condition

If the tool holder is damaged or deformed, the accuracy of the cutting plate will be poor.

– Blade clearance

Blade clearance is particularly important in the cutting process. Before cutting, the user must determine and adjust a correct blade clearance according to the plate thickness and material.

At this time, it will be convenient to choose a high-end CNC guillotine shear hydraulic metal sheet cutting machine. Input the plate information into the CNC system, then system will automatically calculate the reasonable blade clearance. You can also manually fine tune it according to the actual situation.

The processing of shearing machine has its precision range, you should select the processing method reasonably and economically according to your own requirements.

Shearing positioning method:

The positioning methods of guillotine metal shears mainly include back gauge cutting method and line cutting method.

Due to the need for visual measurement of the positioning of linear shear accessories, line cutting accuracy is obviously not as good as that of relying on the back gauge mechanism.

So the special-shaped work parts, large parts, and tails all require guillotine shear back gauge cutting.

Especially for thick plate and large plate, it is difficult to fine tune and position the liner shear because of its heavy weight. To prevent poor machining accuracy, users need to be very careful or customize special positioning device during operation.

Movement and deformation of plates:

Plate cutting is an extremely complex process. For sheet metal parts, it is difficult to avoid the edge and section defects and deformation. It mainly includes section slope, bed surface uplift and shear edge deformation.

Also, the plate may move randomly because of the factors such as too large shear force required by thick plate, less presser foot on parts, and failure of presser foot. This will all lead to shearing parallelism error, thus affecting the size of the part.

Manual operation:

As we all know, manual operation has a great influence on the accuracy of plate shears. Therefore, customers should standardize the operation in production and strengthen the inspection of accessories.

In addition, the impact and vibration during the positioning of the back gauge, the droop effect caused by the large shear width (large gravity), positioning error of manual measurement and so on. Above all have an impact on the cutting accuracy.

– The installation is firm without looseness.

– The joints of the upper and lower blades must be flush. That is, the entire blade mechanism maintains a straight line.

– Adjust the gap to make it uniform and stable.

– Before working, the user should adjust the shearing clearance according to the thickness of the plate.

– Master the turning time of the blade. If there is not too much damage, it can be used again after polishing.

– Whether it is a new edge or a polished edge, should be installed, adjusted and used according to the specifications.

These measures can not only improve the working speed and quality, but also greatly reduce the damage degree and frequency.

Correct use of sheet metal guillotine shearing machine can achieve normal cutting accuracy. Wrong operation will not only lead to poor machining accuracy, but also cause safety accidents and machine failures.

– Work in accordance with official operation manual of guillotine shears.

– Prohibit all non-standard operation! Do not cut sheets that exceed the specified thickness and multi-layer stacked sheets.

– Make sure that the equipment works well, especially the tool holder, eccentric sleeve and other key parts.

– Check the adjustment of blade clearance regularly. Solve the problems in time when found.

– It is necessary to change the blade regularly and maintain the machine.

– When the hardness of the plate increases, the manufacturer should increase the edge strength to meet the production needs.

– At the same time, we should also consider increasing the strength of the cutting blade according to the material of the plate, so as to reduce the wear degree and frequency.

Plate processing can not completely avoid any deformation and movement, which will lead to errors. Inconsistent deformations make dimensional tolerances.

In production, we should put thick or large plate in the position where there are more presser feet and the pressure foot force is relatively stable to obtain better dimensional accuracy.

Accurate measurement of data is essential for precision. We should pay attention to observation, comprehensive analysis and calculation.

Please measure two or three positions to reflect the sheet size correctly. Analyze the effect of cross-sectional tilt to avoid defects such as boss, end plate, and excessive burrs.

The system of CNC guillotine sheet metal shearing machines can automatically calculate and compensate the cutting angle by inputting sheet data to improve the accuracy.

CNC system controls the cutting angle and stroke with linear encoder feedback data. The computer stores the corresponding list of shear angle and blade clearance with material. So, that can control the adjustment of blade clearance to improve the cutting precision.

At the same time, we can also increase the configuration to improve the cutting accuracy and quality. For example, add the following devices: anti-twist device, sheet supporting device and front feeding device…

For the user, the cutting accuracy is an important factor for the production quality. CNC hydraulic guillotine metal shear machines have the characteristics of high precision, simple working mode, high efficiency and low cost.

The error range of the Wuxi Shenchong high-precision guillotine shear is ±0.03mm/m, and the laser welding is no more than 0.1mm. So high precision CNC guillotine shearing machine is the best choice for laser welding.