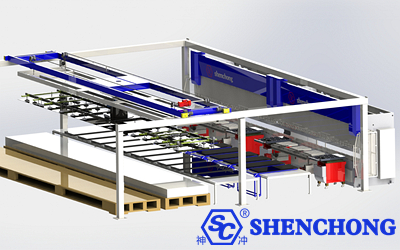

Automatic sheet metal bending utilizes technologies such as robots, servo CNC press brakes, servo drives, and automatic loading and unloading systems to automate the entire sheet metal bending process, from workpiece loading to bending and unloading to stacking.

Compared to traditional bending equipment, automated press brakes offer significant upgrades in structure, control, functionality, and intelligence, resulting in greater efficiency, precision, and flexible manufacturing capabilities.

The automated sheet metal bending system is a core process unit in intelligent sheet metal manufacturing. Its purpose is to achieve efficient, precise, and continuous bending of sheet metal workpieces through mechanization and intelligent control.

An automatic sheet metal bending machine (a high-precision CNC press brake machine + intelligent control system + automated mechanical structure) is the core equipment for modern sheet metal manufacturing, achieving "efficiency improvement, flexible production, and intelligent management and control."

Function: Performs bending operations, deforming sheet metal to predetermined angles and shapes.

Features: Equipped with a servo system, electro-hydraulic synchronous control, angle compensation, etc.

Types: Electro-hydraulic synchronous press brake, electric press brake, servo electric press brake, etc.

Function: Grasps workpieces and performs bending operations according to a set motion path.

Types:

Industrial robot arms (such as ABB, KUKA, and FANUC) (etc.)

Truss/Gantry Handling System (suitable for heavy or long workpieces)

Components:

End-of-line grippers (replaceable grippers, vacuum cups, etc.)

Rail motion system (extends the working range)

Safety fence and sensor system (ensures operator and machine safety)

Function: Assists in supporting large or heavy workpieces to prevent sagging, deformation, or angular errors

Type:

Electric lift follower table

Automatic follow-up support arm

Interaction: Synchronizes with the bending angle to improve bending quality and consistency

Function: Enables automatic workpiece loading, unloading, stacking, or transfer

Components:

Sheet material feeding platform

Loading robot/suction cup arm

Finished product stacking unit

Supplementary modules (optional):

Turning mechanism (supports front and back processing)

Clean/dust blowing mechanism (ensures cleanliness of finished products)

Function: Enables centralized control, path planning, and automated scheduling of the bending process

Components:

Press brake controller (e.g. Delem, ESA, Cybelec)

Robot controllers (such as KUKA KRC, ABB IRC5)

Offline programming software (AutoPOL, Metamation, RoboBend)

Graphical user interface (HMI)

Intelligent features:

Automatic angle correction

Mold database management

Remote monitoring and diagnostics

Function: Complete sheet metal bending

Features:

Standard molds (V-type, U-type, etc.)

Quick mold changer (mold library + automatic changer)

Specialized molds (for specific bend shapes)

Function: Connects to enterprise production management systems to enable production line data interconnection, task assignment, and progress tracking

Advantages:

Full-process data collection and traceability

Supports flexible production scheduling and visual monitoring

Automated sheet metal bending, a key component in the intelligent upgrade of sheet metal processing, offers significant advantages over traditional manual bending, including improved efficiency, consistent quality, and flexible manufacturing capabilities. Automatic sheet metal bending, with its core characteristics of "efficiency, precision, flexibility, intelligence, and safety," is a key driving technology in the transition of modern sheet metal manufacturing from labor-intensive to intelligent manufacturing.

Automated loading and unloading, fast bending, and stable cycle times.

Supports 24/7 unmanned continuous production.

A single program can be run repeatedly without resetting each time.

For example, a single automated bending line can replace two to three teams of skilled workers, significantly increasing production capacity.

Bending robots offer repeatable positioning accuracy of ±0.05mm.

CNC press brakes feature angle compensation and feedback systems for controllable precision.

Eliminate human error and achieve high dimensional consistency in batches.

Addresses the shortage of skilled workers.

Reduced labor intensity and improved working environment (oil-free, highly safe).

Newcomers can quickly master system operations without years of experience.

Quick mold change and automatic identification systems enable rapid switching between product types.

Offline programming systems (such as AutoPOL) support complex part paths Rapid production.

Adapts to the trend of customized and small-batch orders.

Can be integrated with MES/ERP systems to connect production line data chains.

Enables production capacity data collection, order tracking, and quality traceability.

Laying the foundation for the future "dark factory".

Stable bending angles reduce rework and scrap.

Reduces mold wear and extends mold life.

Automatic positioning avoids repeated or misaligned bending.

Quickly switch between production tasks.

Processing data can be saved and recalled at any time, enabling flexible and efficient order response.

Shortened delivery cycles and increased customer satisfaction.

Comparative Dimensions | Traditional manual bending | Automatic bending |

Efficiency | Relies on worker skill, resulting in high efficiency fluctuations | Continuous operation, stable cycle time, high production capacity |

Accuracy | Susceptible to human interference | CNC precision control, high repeatability |

Safety | Manual operation carries the risk of pinching fingers | Fully enclosed protection, high safety factor |

Manpower Requirements | Skilled workers are difficult to recruit and costly | Reduced reliance on manual labor, adapting to labor shortages |

Flexible Production | Slow changeovers and cumbersome programming | Supports rapid switching between multiple products, program saving |

Data Management | Relying on manual record-keeping | Connects to MES/ERP for automatic recording and traceability |

Featured Categories | Features |

Automation | Fully automated bending process |

High Precision | CNC + compensation system, controlled angular error |

Flexibility | Quick changeover, supports multiple products on the same production line |

Intelligence | Data traceability, remote monitoring, and intelligent production scheduling |

Safety | Fully enclosed protection + multi-sensor interlocking |

Energy Saving and Environmental Protection | Servo drive, low noise, and low energy consumption |

When selecting an automated bending system, a comprehensive evaluation should be conducted based on factors such as processing requirements, production volume requirements, workpiece size and shape, budget, and future scalability. The following are practical automated bending system selection recommendations:

- Bending material and thickness: Is it carbon steel, stainless steel, or aluminum alloy? What is the thickness?

- Workpiece size and weight: Large plates require a follower or gantry; small parts are suitable for robotic gripping.

- Production requirements: For large batches, a fully automated unit is recommended; for small and medium batches, a flexible solution is recommended.

- Product changeover frequency: For high-volume, low-volume production, flexible changeover capabilities are more important.

- Is it integrated with upstream and downstream equipment: Is it integrated with punching, laser, welding, or storage systems?

Application Scenarios | Recommended Configuration | Features |

Standard small and medium-sized workpieces (<20kg) | Bending Robot + CNC Press Brake | Proven solution, high efficiency, suitable for continuous production |

Large/long workpieces (>1500mm) | Bending Machine + Follow-Up Support + Loading and Unloading Mechanism | Prevents workpiece sagging and provides stable bending. |

Medium and thick plate processing (≥6mm) | Heavy-Duty Press Brake + High-Load Robot | High-torque drive, excellent stability |

Small-batch/multi-variety flexible processing | Bending Robot + Quick Die Change + Intelligent Programming System | Fast changeover, suitable for flexible production |

Automated loading and unloading requirements | Unmanned operation, high efficiency | |

Automated stacking of finished products | Post-Bending Stacking System | Neat finished product output, facilitating subsequent logistics |

- Press brake control systems: ESA, Delem, Cybelec, etc., supporting robot linkage interfaces

- Robot control systems: KUKA, ABB, FANUC, etc., pay attention to compatibility with the press brake

- Offline programming software: RoboBend, Metamation, AutoPOL, improve changeover efficiency

- MES system interface: supports production data collection and scheduling collaboration

- Frequent die changes? An automatic die changer (ATC) system is recommended to enhance flexibility.

- High precision requirements? Optional precision accessories such as angle compensation systems and laser centering devices are recommended.

- Budget constraints? Start with a "semi-automatic" system with a reserved upgrade interface and gradually expand.

- Factory space constraints? Prioritize compact cell layouts or mobile robot structures.

- Don't blindly pursue "full automation"—the system should be tailored to actual production capacity and management capabilities.

- Robotic gripping solutions should fully consider practical issues such as workpiece deformation and slippage. - Whether the bending tools and dies support the robot's gripping angle is a key factor in selecting the right bending tool.

- Whether the system manufacturer provides ongoing training and maintenance services is a key factor in ensuring a successful selection.

Automatic sheet metal bending is a form of intelligent manufacturing that deeply integrates traditional bending processes with robotics, CNC systems, intelligent software, and automatic loading and unloading equipment. It not only improves production efficiency and precision, but also greatly enhances production flexibility and intelligence.

If you can provide the following information, we can provide you with more specific selection recommendations:

- What sheet metal sizes, thicknesses, and materials are commonly processed?

- What is the daily/per-shift processing volume? Do you frequently change over?

- What existing equipment do you have (such as laser cutting, punching machines, etc.)?

- What are your automation budget and factory layout constraints?