Choosing the best steel plate cutting machine requires considering multiple factors, including processing requirements, machine performance, budget, and after-sales service. Below is a detailed selection guide.

A practical, step-by-step selection process:

From workpiece requirements → machine model → key parameters → control/automation → supplier and after-sales service.

The steel plate shearing machine's rated cutting thickness should be greater than or equal to the maximum thickness of the sheet you typically use (a 10-20% margin is recommended).

For example, if you frequently cut 10mm thick steel plate, it's recommended to select a shearing machine with a thickness of 12mm or greater.

The machine's worktable length should be greater than the maximum sheet width. Common widths include 2500mm, 3200mm, and 4000mm.

The desired thickness range and maximum cutting length are the primary factors in determining the strength and model of the machine tool frame.

Ordinary carbon steel, stainless steel, and high-strength alloy steel have different shear resistances, so you need to select the appropriate tool material and machine model.

The material you're cutting (e.g., cold-rolled, hot-rolled, stainless steel, aluminum) will affect the required force and blade material. The varying rigidity and elasticity of different materials can affect burrs and bends.

What are your precision requirements? Do you want to move directly to bending/welding/assembly? If the precision requirement is very high (±0.1mm level), guillotine or high-precision CNC plate shearing machines are preferred.

Offers high straightness and strong shearing capacity, suitable for thick and large plates.

Disadvantage: Higher price.

Simple structure, low cost, suitable for shearing medium and thin plates.

Disadvantage: Poor shearing accuracy for thick plates.

Automatically adjusts blade gap and shearing angle, offering high precision.

Can be integrated with automatic feeders/stockrooms to improve efficiency.

Suitable for high-end processing companies.

- Cutting capacity (thickness × length): Machine models are typically listed as "6×3200" (6mm × 3200mm). Always allow for margin (for anticipated capacity expansion/harder materials).

- Blade clearance adjustment: Manual/electric/CNC, which affects cut quality.

- Cutting angle: Adjustable, helps minimize sheet deformation.

- Pressing method: Hydraulic press provides greater stability and prevents sheet slippage.

- Back gauge: CNC backg auges offer higher precision and support batch processing.

- Control systems: ESTUN, Delem, or ELGO systems.

- Cutting accuracy/straightness: If post-processing does not allow for trimming, choose a machine with high-precision specifications and marked cutting straightness (some manufacturers can achieve ±0.03mm/m).

- Tooling (blade material and reversible blade/four-edged blade): This can extend tool life and reduce maintenance costs.

- CNC/CNC Backgauge: Automatically memorizes programs, controls cutting length, and optimizes feeding, significantly improving efficiency and reducing manual error. Common control brands/systems (e.g., Delem, ESTUN, etc.) will affect ease of use and maintenance.

- Whether front feed, automatic feed table, material rack/tumbler, or automatic loading and unloading are required: This decision is determined by production volume and labor costs. The higher the automation level, the greater the investment, but the lower the unit cost.

- Structural Materials: Is the frame welded from high-strength steel plates and tempered for stress relief?

- Hydraulic System: Are reputable hydraulic components used (e.g., Rexroth, Eaton)?

- Blade Materials: Commonly used materials include 9CrSi, 6CrW2Si, and H13K; durability varies significantly between different materials.

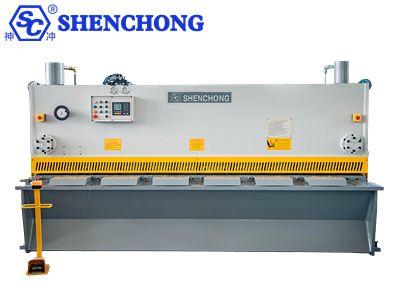

- Reliable Brands: Common domestic brands include Shenchong, Yangli, Yawei, and Jinfangyuan; international brands include Amada, Accurpress, and Durma.

- Swing Hydraulic: Relatively affordable, suitable for small and medium-sized factories.

- NC Guillotine Hydraulic: Expensive, but long-lasting and a must-have for thick plates.

- CNC/Servo: High initial investment, but highly automated, suitable for large-scale production.

- After-Sales Service: Availability of local service locations and prompt repairs.

- Accessories: Ease of replacement of blades, hydraulic components, CNC systems, etc.

- Automation Expansion: Compatibility with automated loading and unloading, material storage, and other systems to increase production capacity.

- Choose a good steel plate shearing machine manufacturer with strong after-sales service, spare parts distribution, technical support, and local service locations. Confirm the availability and delivery time of key spare parts, such as blades, hydraulic components, and electrical components.

- Require the manufacturer to provide on-site inspection/test cutting samples, operator training, and standard warranty terms (including a policy for wear and tear of key components).

Below is a table of recommended steel plate cutting machine parameters organized by common plate thicknesses (6mm, 12mm, 20mm, and 30mm) plus a comparison of typical machine parameters. This will help you quickly determine which model best meets your needs.

Plate thickness | Recommended cutting width (plate lengthwise) | Recommended shear types / key parameters | Suitable applications/Precautions |

6mm | Approximately 2500-4000 mm | - Small to medium-sized hydraulic guillotine shears - Blade gap adjustment + adjustable rake angle - Pressing device + back gauge - Medium-tonnage hydraulic system, requiring minimal horsepower | Used for thin plate parts and small batch production; low cost, requires sharp blades + uniform pressing to avoid edge warping |

12mm | Approximately 2500-4000 mm | - Hydraulic guillotine shears or heavy-duty models - High-strength frame structure - Powerful material holding system - Stable blade material + excellent heat dissipation/lubrication | Heavier plates have a higher risk of deformation and require controlled bevel angles and clearances. The startup impact is large, so the hydraulic system capacity and stability must be ensured. |

20mm | Approximately 2000-3000 mm | - Heavy-duty hydraulic guillotine shears (possibly CNC-assisted) - Wear-resistant blade material - Sufficiently rigid hold-down and pressure rods - Powerful hydraulic pump and high-power motor support | Used for cutting structural parts and large steel plates; the machine body is thick enough to bear the shear force; the production cycle is long and the efficiency is relatively low; the maintenance cost is high |

30mm | Approximately 2000 mm or less (depending on equipment capabilities) | - Extra-heavy duty shears, customizable options available - High level of CNC/automation - Reinforced frame welds & tempered for stress relief - Heavy-gauge and durable blades and hydraulic components | Mostly used for large structural steel, bridges, and building steel structures; large investment, transportation, and installation costs; processing deformation problems are more serious, and the blade gap and bevel angle must be strictly controlled. |

Suppose you have a production requirement, for example:

- Mainly cut 10-12 mm carbon steel;

- Maximum plate width is 3000 mm;

- Occasionally cut 6 mm or 8 mm, but in small quantities;

- Precision requirements are moderate, with acceptable edge tolerances.

12 mm | 2500-4000 mm → Ideal

You are looking for a hydraulic guillotine shear or a CNC/NC back gauge with press and bevel adjustment.

When searching for a machine model, check whether it can support a 12 mm MS, 3000 mm length, and whether the machine has a rigid structure.

- Sample Cutting: Test cut on your frequently used material to check for size, burrs, and straightness. (Required)

- Is it convenient to adjust the blade gap and cutting angle? Is the knife reversible or easy to replace?

- Is the hydraulic/electrical layout neat and tidy? Are there well-known brand components (valves, pumps, PLC, etc.)?

- Back gauge accuracy and repeatability (if CNC back gauge is used).

- Is the user-friendly interface friendly? Can programs be saved, imported, or exported?

- Only considering "maximum thickness" without considering material type/strength (carbon steel and stainless steel require different allowances).

- Ignoring tool and spare part costs and lead times, resulting in downtime waiting for parts.

- Insufficient automation configuration while business is moving toward high-volume production, resulting in limited efficiency or high subsequent modification costs.

Actual Requirements (Thickness + Width + Material) + Equipment Type (Swinging/Guillotine/CNC) + Brand Quality + Budget and After-Sales Service = The Best Steel Plate Cutting Machine

- List the material/thickness/maximum length/precision you need to cut.

- Based on precision and length, prioritize gate/front-feed CNC or swing beam models.

- Select models based on cutting capacity, kerf adjustability, throat depth, control system, and degree of automation.

- Perform a test cut at the manufacturer, verify after-sales service and spare parts availability, and compare the total cost of ownership (machine price + cutting tools + spare parts + service).