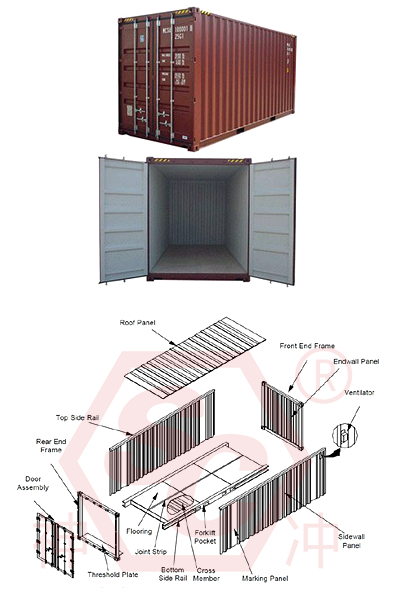

A container is a group of tools that can carry packaged or unpackaged goods for transportation and facilitate loading, unloading, and transportation using mechanical equipment. The container manufacturing is generally standardized assembly lines. The process flow is divided into stamping, bending, welding, spraying, and assembly.

Container transportation is an important mode of transportation in the multimodal transportation of international trade goods. Due to the advantages of high standardization, good sealing, low damage rate, intensification, scale, liner, low cost, and good quality in container transportation, the safety and efficiency of cargo transportation have been greatly improved.

The manufacturing and production of containers is an assembly line. A standard container consists of five parts: front end, rear end, chassis, top plate, and side plate. The container manufacturing process is divided into four primary processes: stamping, welding, spraying, and completion.

Steel uncoiling, flattening → cutting → shot blasting → spraying workshop primer → drying → cold processing, forming → component assembly, welding → general assembly, welding → whole box welding and sandblasting → spraying primer first class leveling, drying → pre-coating of middle and inner coatings → spraying of middle and outer coatings → leveling, drying → pre-coating of outer coatings, spraying of outer coatings → leveling, drying → assembly of the completion line → nameplate, sealant Labeling → Asphalt paint and water tightness test at the bottom of the box → Finished box outgoing line.

The manufacturing materials of containers refer to the materials used for the main components of the container (side walls, end walls, top, etc.), which can be divided into three types: steel containers, aluminum alloy containers, and fiberglass containers. In addition, there are wooden containers, stainless steel containers, etc. These metal plates are processed by uncoiling, flattening, shearing, stamping, bending, welding, and spraying to become containers.

Including four parts: uncoiling, sanding, cutting, and forming.

- Uncoiling is the process of rolling steel into flat plates.

- Sanding is the process of using a certain speed of fine steel sand to impact the surface of steel and remove rust stains on the data surface. Leave concave and convex pits on the steel surface (to increase paint adhesion).

- Blanking

- Shaping

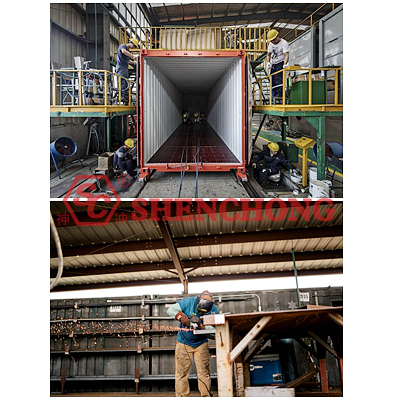

The parts are formed through processes such as bending, pressing, rolling, punching, shearing, and edge cutting. In this step, you can use a CNC press brake to bend the panel of the container. High quality bending machines are more efficient. Also, the processed cabinet panels will be more exquisite.

CNC Press Brake For Container Manufacturing:

Servo Hybrid Press Brake For Container Bending:

The formed and processed sheet metal is welded to form parts and assemblies.

Two layers of paint are required inside the box. Three layers are required externally. Each layer of paint has strict film thickness regulations, ensuring that the paint will not peel off for 3-5 years. Therefore, the preparation of the spraying itself is also important. So before spraying, there is a preparation work for polishing.

The completion section is a section with dense workstations and tight processes.

This section can be roughly divided into eight steps:

- Floor

After the box comes out of the drying room and cools down slightly, first place it on the middle beam of the floor. Then apply sealant to all areas that come into contact with the wooden floor, and finally lay the floor.

- Punching floor nails

The wooden floor adopts self tapping screws, which need to be drilled on the floor and chassis first and then tightened.

- Install nameplate and ventilator.

- Install door tape: Insert sealing tape on the door panel frame to prevent container leakage.

- Cleaning: Remove residual wood and iron shavings from the floor.

- Locking rod: Install the locking rod assembly onto the door panel.

- Sticker: Affix the customer's trademark and box number.

- Water test: Conduct water pressure test and light test to check the sealing of the container.

The rapid development of container transportation has driven the prosperity of container manufacturing industry. The container manufacturing industry mainly includes the manufacturing of various special containers such as dry cargo containers, refrigerated containers, and tank containers. The manufacturing of these containers will use such sheet metal processing equipment, such as uncoiling lines, shearing machines, laser cutting machines, bending machines, CNC punching machines, and so on. Welcome container manufacturers to inquire about processing equipment!