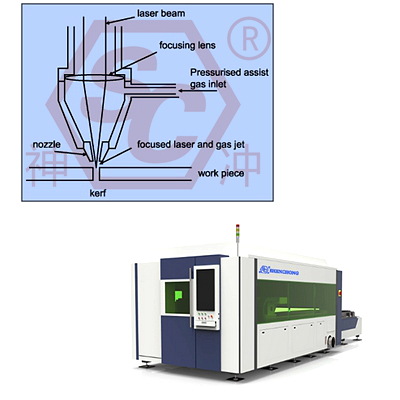

CNC laser cutting machines focus the laser emitted from the laser into a high-power laser beam through an optical path system. The laser beam irradiates the surface of the work piece to reach the melting or boiling point, while the high-pressure gas coaxial with the beam blows away the melted or vaporized metal. As the beam of light moves relative to the work piece, the material eventually forms a cutting seam, thereby achieving the purpose of cutting.

Laser is a type of light that, like other natural light, is generated by the transition of atoms (molecules or ions, etc.). But it differs from ordinary light in that the laser only relies on spontaneous radiation for a very short period of time, and the subsequent process is completely determined by excitation radiation. Therefore, lasers have very pure colors. Almost no divergent directivity, extremely high luminous intensity and high coherence.

Laser cutting is achieved by applying the high power density energy generated by laser focusing. Under the control of a computer, the laser is discharged through pulses to output a controlled repetitive high-frequency pulse laser, forming a beam of light with a certain frequency and pulse width. The pulsed laser beam is transmitted and reflected through the optical path, and is focused on the surface of the processed object through a focusing lens group, forming tiny, high-energy density light spots. The focal spot is located near the surface to be processed and melts or vaporizes the processed material at an instant high temperature.

Every high-energy laser pulse instantly ejects a small hole on the surface of the object. Under computer control, the laser processing head and the processed material move continuously relative to each other according to a pre drawn pattern, which will process the object into the desired shape.

The process parameters (cutting speed, laser power, gas pressure, etc.) and motion trajectory during cutting are all controlled by the CNC system, and the slag at the cutting point is blown away by a certain pressure of auxiliary gas.

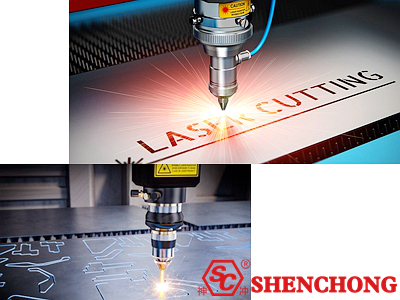

Laser cutting processing replaces traditional mechanical knives with invisible beams of light. It has the characteristics of high precision, fast cutting, not limited to cutting pattern limitations, automatic layout saving materials, smooth cutting, and low processing costs. It will gradually improve or replace traditional metal cutting process equipment.

The mechanical part of the laser blade does not come into contact with the work piece, and it will not cause scratches on the surface of the work piece during operation. Laser cutting speed is fast, and the incision is smooth and flat, generally without the need for subsequent processing.

The cutting Heat-affected zone is small, the plate deformation is small, and the cutting seam is narrow (0.1mm ~ 0.3mm). The incision is free of mechanical stress and shear burrs. Can process any floor plan. It can cut whole boards with a large format. No need to make a mold. Economically time-saving.

Click here to know Laser Cutting Automatic Production Line

Laser cutting machine is a cutting equipment used for cutting and processing metal materials. During homework, CNC laser cutting machines have the characteristics of fast cutting speed and high cutting accuracy. Therefore, it is also widely used in different industries. So, what are the components of a laser cutting machine?

The frame, crossbeam, workbench, Z-axis system, gas control system, electric control system, transmission system, protective casing, safety system, etc. of the laser cutting machine are collectively referred to as the host. Exciting

When cutting with a cnc laser cutting machine, the workpiece is first placed on the workbench. Then use a servo motor to drive the crossbeam and control the movement of the Z-axis. Users can adjust parameters according to their own needs.

It is the core component of a laser cutting machine and the "power source" for achieving cutting operations.

The cutting head of a laser cutting machine is a laser output device. It consists of a nozzle, a focusing lens, and a focusing and tracking system.

The cutting head will walk according to the set cutting trajectory. However, under different materials, thicknesses, and cutting methods, the focus position of the laser cutting head is automatically controlled by CNC.

The water cooling device is the cooling device of a laser cutting machine. It can quickly and efficiently cool devices such as lasers and spindles.

Nowadays, cold water devices all include advanced functions such as input and output control equipment switches, cooling water flow, and high and low temperature alarms. More stable performance.

Servo motor refers to the engine that controls the operation of mechanical components in a servo system. The servo motor can control the speed. The position accuracy is very accurate. The control signal can be converted into speed and position to drive the control object.

High quality servo motors can effectively ensure the cutting accuracy, positioning speed, and repeated positioning accuracy of laser cutting machines.

The gas supply system of the cnc laser cutting machine mainly includes gas source, filtering device, and pipeline. The gas sources include bottled gas, liquefied gas, and compressed air.

It mainly controls the machine tool to achieve the movement of the X, Y, and Z axes, while also controlling the output power of the fiber laser cutting machine.

The above parts are important components of CNC laser cutting machines. Moreover, due to different models and brands, there are still differences in the components that make up the laser cutters. Therefore, when choosing a laser cutting machine, it is still necessary to have a deep understanding of the brand, reputation, actual operating scenarios, and usage of the laser cutting machine. Based on the production purpose and usage scenario of the enterprise, choose the laser cutting machine that is suitable for you.