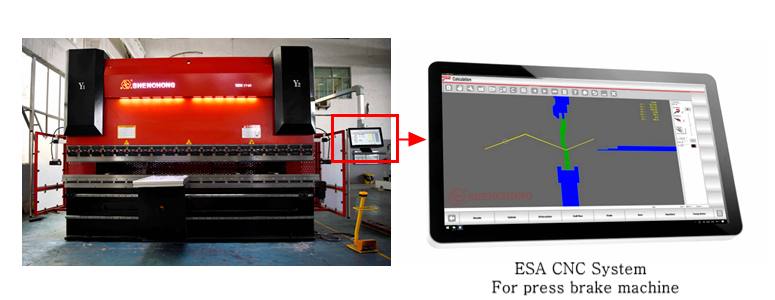

CNC press brake programming has always been a difficult point for users, especially for novices. How to install and set up a CNC brake press? How to program the CNC system? How to adjust the parameters? These are all very troublesome problems for customers. Now, we will answer for you one by one. Take the ESA commonly used CNC system as an example. Tell you the steps and key points of programming CNC press brakes with ESA system.

After purchasing a CNC bending machine, do you feel at a loss and unable to start. This is an obstacle for many customers.

When we get a brand new press brake, how do we start to set it up? What is the correct operation? We should make full preparations before officially starting to use numerical control equipment for processing.

Before we start programming, our first task is to prepare for startup. Using proper press brake setup procedures, the steps are as follows:

- Turn on the machine: twist the key and open the pump.

- Double press “ESAbend” on the screen, open the system.

- Press manual, then press “repeat calibrat“, then step the ram up.

After completing the above steps, our bending machine and ESA system will start.

CNC press brake applies certain pressure through specific upper and lower dies to process sheet metal forming. So punches and dies are very important tooling of CNC press brake machines.

However, tool programming is always a headache for users. When you purchase a new press brake, how to add or edit a new punch and die programme?

Take ESA CNC control system as an example. Follow the 7 steps in the video:

- Press tool button, edit the width and height.

- Follow our engineer in the video to edit your new tools.

- Press “SAVE”, then name it.

- Press “Tool” button, edit a new punch.

- Press “New Type”, input total height and reference height.

- Follow our engineer in the video to edit your new tools.

- Press “SAVE”, then name it.

Through the above operations, you can successfully edit or add mold bending programming. If you want to add more tools, just repeat the above steps.

In daily work, users will have different sheet metal plate and bending requirements. How to program the CNC Press Brake? The key point of CNC press brake programming is to set and add various work steps.

When you want to bending a work piece, how to programme the step in the ESA CNC controller? How to add one step or multi-steps? Follow the steps in the video.

Program new bending:

In “editor” page, press “new program”, input “width”, “thickness” and “material”. Choose “punch and die”.

Program one step:

- Y1, Y2 are angles.

- X1 is backgauge stroke.

- R1 is up and down, it’s an automatic value.

- Z1, Z2 is block fingers stroke.

- A1 is automatic front support, no need set.

- Press “single step” button.

- Start semi-automatic bending.

- Press green button to start the programme.

Program muti-steps:

- Back to “editor”, press “next” button to program more steps.

- Back to the first step, press “automatic” button.

- Press green button to start bending.

According to the above steps, you will edit a bending or multi working steps well.

Like all CNC equipment, it is very important to turn off the CNC bending machine correctly for its maintenance. Direct and rude power-off is very unprofessional. In this way, the equipment and controller will be damaged and the system data will be lost.

When the user finishes a tiring day of sheet metal processing, how to shut down the ESA controller and its bending machine in an orderly manner? Do as the video.

- Turn off the press brake machine

- press “manual”, than step down the ram to bottom.

- Pay attention to leave a little gap between the punch and die.

- Exit the ESA CNC system.

- Press the black button to stop power.

CNC press brake control system is like human brain. It controls the whole work and stores all data. Please be sure to CNC press brake programming and use the system correctly according to the operation manual and instructions! Beware of faults.