Summary:

Press brake punch and die are key components of CNC press brake machine. This article will tell you how to choose and use them.

Press brake punch and die are tools for bending equipment to make flat sheet metals into three-dimensional work pieces through hydraulic pressure.

As a key tool of processing and forming, press brake dies and punches are very important in the selection and use of press brake machine.

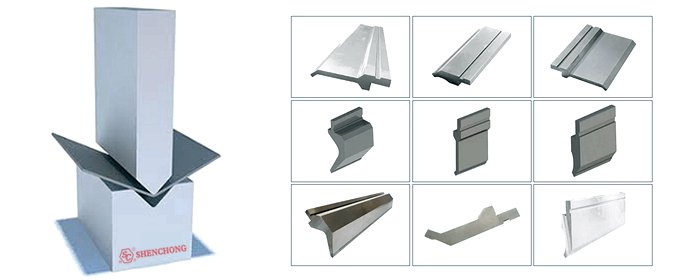

Press brake punch and die are divided into standard tools and special bending tools according to the bending process. If normal bending (right-angle and non-right-angle bending), we generally choose standard tools for bending; and if special workpiece (step bending, box bending). We need choose special tools, such as press brake box punch and die, etc.

The normal bending angle is generally not less than 90 degrees. The angle of the punch and die of the press brake tooling is usually 88 degrees. In the case of non-standard bending, different upper punch shapes can be selected, and different angles and shapes of sheets can be bent. For special shapes workpiece, we can choose a special forming press brake tooling.

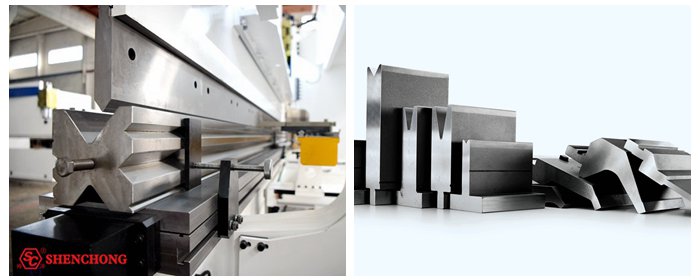

In addition, for different thickness of sheet metal plate, the size of the of the bottom die opening is different. Generally, the opening size of the "V" groove is 6-10 times of the plate thickness (0.5-2.6mm is 6 times, 3-8mm is 8 times, 9-10mm is 10 times, 12mm or more is 12 times).

When thin sheet, we choose a small multiple; and when thick plate, we choose a large multiple. For example: when bending 2mm thick plate, we can choose 12mm V groove on bottom die.

Normally, the punch and die length of press brake machine is 835mm. Usually only large-size work pieces can be bent.

If the press brake tools are divided into small sections, and combined freely into different lengths. It will be convenient to bend box-shaped workpieces or other special work pieces.

There is a standard segmentation size for 100 (left ear), 10, 15, 20, 40, 50, 200, 300, 100 (right ear) = 835mm. The used brake press punch and die can also be divided into didfferent sections according to user requirements.

- Turn on the press brake machine power, turn the key switch, press the oil pump, press brake machine oil pump starts to rotate, the machine has not yet started working.

- The stroke adjustment requires a trial run when the press brake punch and die using. There must be a plate thickness gap when the bending machine punch approaches to the bottom. Otherwise it will cause damage to the tools and the machine.

- We usually choose bottom die V oepning by 8 times of the plate thickness. If bend a 4mm sheet, we need to choose the V opening about 32mm.

- Check the overlap and firmness of the press brak punch and die; Check whether the toolings meet the processing requirements. Frequently check the overlap of the upper and lower tools; whether the instructions of the pressure gauge meet the regulations.

- When the sheet is bent, we need pay attention to whether the sheet will warp during bending, which will hurt the operators.

- The power supply must be cut off before adjusting the press brake punch and die clamp.

- When changing the opening of the press brake lower die, no material is allowed to contact the lower die.

- It is forbidden to use press brake machine tools to fold over-thick iron plates or quenched steel plates, high-grade alloy steels, square steels, and sheets that exceed the press brake machine capacity, avoid damage to press brake tools and the machine.

- Turn off the bending machine, and place wooden blocks on the lower die which also under the both side cylinders, then move the ram slide onto the wooden blocks. Exit the control system program first, then cut off the power supply.

- Under full load, the work piece should be at 2/3 of the stress line.

- Do not bend over-narrow work pieces, so that it is not easy to damage the accessories.

- The angle of the punch must be less than 2-5 degrees of the bending angle.

- Keep press brake toolings clean!

- Clean up the garbage in the press brake bottom die.

- Frequently use antirust oil.

- Press brake upper punch must not be greater than the angle of the Vee die

- The angle of the press brake punch must not be greater than that of the lower die.

Wuxi shenchong supply a large range of press brake punch and die sets, adaptors and press brake punch and die clamp to suit most types of press brake bending machines. Welcome to contact us for more details!