The press brake tooling is roughly composed of four parts: upper punch, lower die, guide rail and die base. The angle is divided into three specifications of 88°, 90° and 30° (except for special tooling).

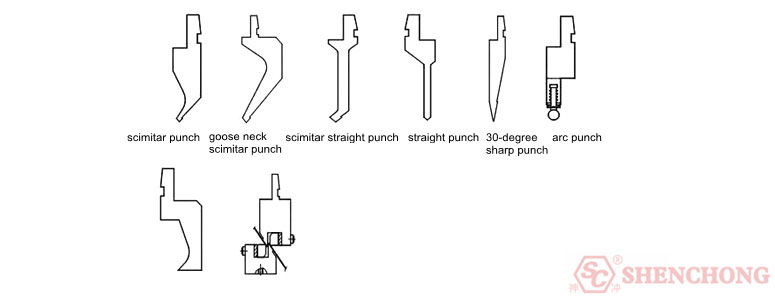

Straight punch, scimitar punch, goose neck scimitar punch, 30-degree sharp punch, flattening punch, simple punch, special punch, arc punch, etc.

The common types are R=0.2, R=0.6, and the tool angles are 88° and 90°.

The common types are shown in the figure below:

The upper punch of the press brake has two types: integral type and split type;

Length of integral upper punch (mm): 835

Split type upper punch length (mm): 10, 15, 20, 40, 50, 100, 200, 400

Double V slot V4-V7 V5-V9 V6-V10 V7-V11 V8-V12 V15-V18, etc.

Single V slot V4 V5 V6 V7 V8 V10 V12 and so on.

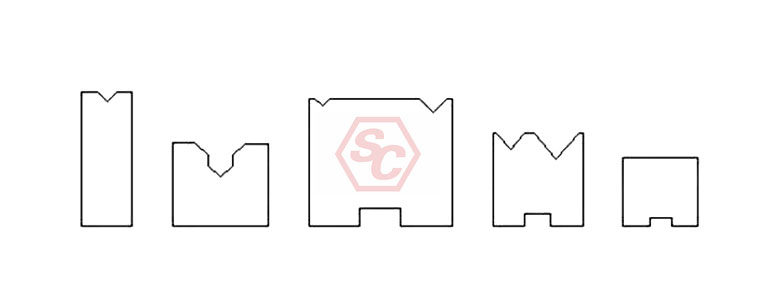

The press brake V die (also called V groove) commonly used V groove sizes are: V4, V5, V6, V7, V8, V10, V12, V16, V25.

For example: “V5” means that the V-groove finish is 5mm. Commonly used V-groove angles are: 88° and 90°. The common types of lower die of bending machine are shown in the figure below.

The common types of lower die of bending machine are shown in the figure below:

There are also some special lower dies: rolla-v press brake die, forming lower molds, etc.

The lower die of the press brake also has two types: integral and split:

Length of integral lower die (mm): 835

Split type lower die length (mm): 10, 15, 20, 40, 50, 100, 200, 400

Die base part: single-slot die base and double-slot die base. There are three types of double-slot die base: low station, middle station and high station.

- The press brake toolings is made of high-quality steel after special heat treatment, which has the characteristics of high hardness, not easy to wear, and high pressure. But each toolings has its ultimate pressure: ton/m, so the length of the toolings must be selected correctly when using the toolings.

- That is, how much pressure must be added per meter, and must not exceed the pressure marked on the toolings.

- In order not to damage the toolings, we stipulate that when aligning the origin, the upper punch and lower die with a length of more than 300mm must be used for the origin. The upper punch and lower die of the same height can be used after the origin is aligned. It is strictly forbidden to use the split small toolings to align the origin, and the origin must be based on the origin pressure inside the machine.

- When using toolings, due to the inconsistent heights of various toolings, toolings of the same height can only be used when selecting toolings on a machine, and toolings of different heights cannot be used.

- When bending products with extremely hard hardness or thick sheets, it is not allowed to use toolings to bend steel bars or other cylindrical products.

- When bending sharp corners or pressing dead corners, a 30-degree upper punch should be used. Fold the acute angle first, then press the dead edge. When bending R angle, R upper punch and R lower die should be used.

- When bending long workpieces, it is best not to use segmented toolings to reduce the indentation of the punch, and it is best to choose a single vee, because the outer angle R of the Vee of the single vee lower die is large, and it is not easy to produce bending indentation.

- When using the toolings, the appropriate CNC brake press v-die and punch should be selected according to dimensions and material. Generally, the lower mold is used according to the standard of 5~6T, and the length is longer than the sheet. When the material is harder and thicker, a lower die with a wider slot should be used.

- When selecting the upper punch, which kind of upper punch to use, we should understand the parameters of all toolings, and then decide which upper punch to use according to the shape of the product that needs to be bent.

Wuxi Shenchong recommends that customers choose the most suitable products when selecting sheet metal equipment accessories such as press brake tooling.