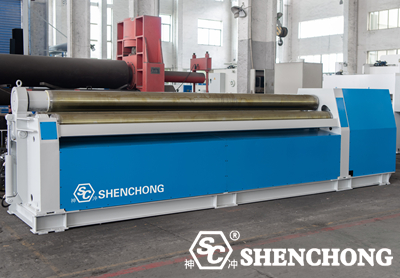

SHENCHONG 4 roller plate rolling machine is a common sheet metal forming machine, primarily used to roll flat plates into cylindrical, curved, or conical shapes. It is similar to a 3 roller plate rolling machine, but with the addition of a lower roll, it offers improved overall performance and greater ease of operation.

A four-roller plate rolling machine consists of a frame, upper and lower rolls, left and right side rolls, a drive system, a hydraulic system, and a control system.

This integral frame structure supports all rolls and transmission components.

It is welded from high-strength steel plates and annealed or aged to eliminate internal stresses and ensure long-term operational stability.

This is typically located at the center of the machine and has the largest diameter.

It is driven by a main motor and a reducer and is the primary power source for rolling.

It applies pressure to the plate, moving it forward and backward.

This is located below the upper roll and can move up and down. During operation, the sheet is clamped against the upper roller and, together with the upper roller, provides friction to drive the sheet.

Located on either side of the upper roller, they can rise and fall along a defined trajectory (usually in an arc or linear motion).

Their primary function is to pre-bend the ends of the sheet to avoid long straight edges.

During the rolling process, the sheet is gradually rolled into a round or conical shape by adjusting the position of the side rollers.

Composed of an electric motor, hydraulic pump unit, reducer, and gear drive.

Typically, a combination of hydraulic and mechanical transmission is used: the upper and lower rollers are driven by a motor. The side rollers are raised and lowered by hydraulic cylinders.

Provides lifting and lowering power for the lower and side rollers, and enables precise pressure control.

The pressure can be adjusted according to sheet thickness and material strength to ensure rolling quality.

Traditional models use manual buttons or PLC control. High-end models use CNC or fully automatic control, which can realize programmed operation and are suitable for mass production.

The forming process of a four-roller plate rolling machine primarily involves four steps: clamping, pre-bending, rolling, and rounding.

The metal plate is fed between the upper and lower rollers.

The lower roller rises, firmly pressing the plate against the upper roller to prevent slippage.

Bend the ends of the plate (pre-bending) by raising one side roller.

Then, switch to the other side roller and repeat the same operation.

This significantly reduces the straight edges at both ends of the plate, preventing defects after welding.

The upper and lower rollers rotate and feed the plate.

The two side rollers gradually rise, applying lateral pressure to the plate, bending it to the desired radius.

The operator can adjust the curvature of the bend by controlling the side rollers.

When the ends of the plate are nearly closed, the rollers are adjusted to achieve uniform roundness.

The resulting cylindrical, curved, or conical workpiece is obtained.

The plate only needs to be clamped once, completing the entire process of centering, pre-bending, rolling, and calibrating, offering high efficiency.

Compared to three-roller plate rolling machines, which require multiple plate flipping, this machine is much simpler to operate.

The side rollers can be raised and lowered to allow pre-bending of both ends directly on the machine.

The remaining straight edge is generally controlled to 1.1–1.5 times the plate thickness, making it easier to weld and reduce scrap.

The plate is always clamped between the upper and lower rollers, preventing it from shifting.

Even force is applied, resulting in minimal roundness error and overall accuracy exceeding that of a three-roller plate rolling machine.

The plate will not slip or flip, ensuring safety.

Many models are equipped with PLC or CNC numerical control systems for programmable automatic rolling.

In addition to cylinders, it can also roll curved, conical, and elliptical cylinders.

By adjusting the asymmetrical positions of the left and right rollers, it can achieve conical cylinder processing.

Suitable for rolling thin, medium, and thick plates.

It is widely used in pressure vessels, boilers, shipbuilding, aviation, petrochemicals, wind turbine towers, and other fields.

No repeated plate turning is required, reducing lifting and manual operation time.

It is particularly efficient for rolling large-diameter thick plates.

1 upper roller (active roller)

2 (or 1) lower rollers, depending on symmetrical/asymmetrical type

Requires plate flipping for pre-bending and rolling.

Remaining straight edge length (usually 2–2.5 times the plate thickness).

Fair roundness accuracy, prone to ovalization.

Low cost, simple structure, and easy maintenance.

Suitable for small and medium-sized plates and workpieces with low-precision requirements.

1 upper roller (active roller)

1 lower roller (holding roller)

2 side rollers (auxiliary pre-bending and forming)

Alignment, pre-bending, rolling, and rounding can be completed in a single clamping operation.

Short remaining straight edge length (only 1.1–1.5 times the plate thickness).

High forming accuracy and low roundness error.

Can roll a variety of cylindrical, conical, and oval workpieces.

High degree of automation and configurable PLC/CNC, high efficiency, relatively high cost, suitable for thick plates, large diameters, and high-precision workpieces.

Comparison Items | 3 roller Plate Rolling Machine | 4 roller Plate Rolling Machine |

Structure | Upper roller + lower roller (2) + side roller (1), commonly available in symmetrical and asymmetrical types | Upper roller + lower roller (2) + side roller (2), symmetrically arranged |

Sheet Clamping | Requires multiple flipping and adjustments to complete pre-bending and rolling | Alignment, pre-bending, rolling, and rounding can be completed in a single clamping operation |

Pre-bending Capacity | Generally requires the use of a press or repeated operation with equipment, resulting in a remaining straight edge length (approximately 2–2.5 times the plate thickness) | The machine itself can perform pre-bending, leaving a short remaining straight edge (approximately 1.1–1.5 times the plate thickness) |

Forming Accuracy | Uneven force distribution, prone to plate slippage, and average roundness accuracy | The plate is constantly clamped between the upper and lower rollers, ensuring uniform force and high roundness accuracy. |

Application Range | Suitable for small and medium-thick plates, generally used in low-end or small- to medium-sized processing plants | Suitable for thin, medium, and thick plates, especially for rolling large diameter and thick plates. |

Operation Difficulty | Complex operation, requiring skilled labor, and high labor intensity | Simple operation, with the option of PLC/CNC automation, reduces labor intensity. |

Processing Efficiency | Low-cost, flipping, centering, and pre-bending are time-consuming | High-performance, single-clamping operation completes the entire process. |

Rolling Shape | Cylinders, partially curved parts, and tapered shapes are difficult to process | Cylinders, curved parts, tapered parts, and elliptical parts can be accommodated. |

Equipment Cost | Relatively inexpensive | Higher costs and greater equipment complexity. |

Application Areas | Suitable for small and medium-sized enterprises and applications with low precision requirements | Suitable for high-end manufacturing applications such as pressure vessels, boilers, shipbuilding, aviation, wind turbine towers, and petrochemical equipment. |

Three-roller plate bending machine → Simple structure, low cost, suitable for lightweight processing.

Four-roller plate bending machine → Strong pre-bending capability, high forming accuracy, and a high degree of automation, suitable for thick plates, large-diameter cylinders, and high-precision products.

The 4 roller plate rolling machine's greatest advantages are its high efficiency, short straight edges, high forming precision, and automated rolling capabilities. Therefore, it is gradually replacing traditional three-roller plate rolling machines in modern manufacturing, and is particularly suitable for large-scale production and thick plate processing.