SHENCHONG 2828 Automated Metal Coil Storage System 2.4tons 7layers is an intelligent warehousing system specifically designed for the storage, management, and automated sorting of thin sheet metal coils (steel coils, aluminum coils, stainless steel coils).

The system utilizes a three-dimensional structure, palletized carriers, and a three-dimensional lifting mechanism to achieve centralized, space-saving, and intelligent management of coils, and can seamlessly integrate with uncoilers, shearing lines, and machining equipment.

- 3D storage saves 60–70% of workshop space

- Pallet capacity of 2.4 tons, 7-layer structure for large capacity

- Automated coil retrieval, reducing forklift operations

- Transparent management, improving raw material traceability

- Supports automatic integration with uncoilers/production lines

- Improved safety and overall efficiency

Suitable for sheet metal processing plants, coil distribution and processing centers, new energy vehicle enclosures, elevators, air handling units, kitchenware, sheet metal OEMs, and other industries.

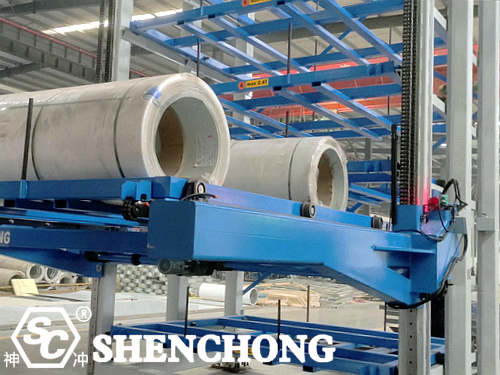

* High-strength steel structure, arranged in 7 layers, each pallet supports a rated load of 2.4 tons.

* Standard U-shaped groove structure

* Suitable for various coil diameters

* Single pallet supports single or multiple coils stored side-by-side (configured according to coil width)

* Servo drive

* Intelligent coil pallet scheduling

* Automatic coil retrieval/warehousing based on task

* Safety light curtain

* Mechanical limit switches

* Full-process anti-collision monitoring

* Warehouse location management

* Automatic scheduling

* Task recording and reporting

* Integration with MES/ERP systems

3D coil storage vertically integrates previously horizontally stacked coils, significantly reducing workshop footprint.

The elevator automatically schedules the selection of a coil pallet, and the system automatically delivers it to the discharge port.

Compatible with:

- Uncoiling lines

- Laser cutting lines

- Slitting/cross-cutting equipment

- Coil delivery workshops

Reduces manual coil handling and frequent forklift operations, lowering:

- Scratches

- Impacts

- Crushes

- Risk of coil falling

The system automatically records:

- Specifications

- Weight

- Batch

- Inbound/Outbound Time

- Discrepancy Alarm

Achieving "coil traceability management".

Suitable for carbon steel coils, stainless steel coils, aluminum coils, galvanized coils, coated coils, etc.

Connectable to:

- Automatic depalletizer

- Automatic loading trolley

- Uncoiling production line

- MES system

Forming a complete smart factory chain.

- Sheet metal processing plants

- Electrical enclosures

- Elevator manufacturing

- New energy sheet metal parts

- Home appliance sheet metal

- Server racks/enclosures

- Refrigeration and fan units

- Metal material distribution centers

2828 Automated Metal Coil Storage System, with a capacity of 2.4 tons and 7 layers, is specifically designed for steel coils, aluminum coils, stainless steel coils, and other metal coils. Through its three-dimensional structure and intelligent scheduling, it achieves a leap from scattered stacking to centralized and orderly management. The system employs pallet-based storage, servo lifting, and intelligent control to fully automate coil storage, retrieval, and management, helping factories improve space utilization and operational safety.

Utilizing a 7-layer three-dimensional structure, a single pallet can hold 2.4 tons of coil material, significantly increasing the workshop's raw material capacity. Servo-driven lifting mechanisms automatically schedule pallets, enabling rapid warehousing and automatic coil retrieval, reducing forklift handling and manual intervention. The system incorporates information management for coil specifications, batches, and weights, achieving digital tracking and visual management of each coil.

Three-dimensional storage of coil materials can save 60-70% of space, significantly improving workshop efficiency. Automated coil retrieval reduces safety risks, avoiding scratches, impacts, and coil rollover accidents. The system seamlessly integrates with uncoiling lines, shearing lines, automated loading trolleys, and MES/ERP systems, providing truly intelligent raw material warehousing solutions for industries such as sheet metal processing, enclosure manufacturing, elevators, and new energy.

SHENCHONG can customize automated storage systems for metal sheets, profiles, and coils according to your factory size, workshop layout, and equipment production needs. Inquiries are welcome!