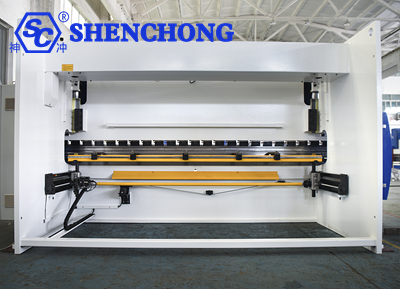

SHENCHONG 175ton CNC hydraulic press brake machine is a large-scale CNC hydraulic bending processing equipment. It utilizes a hydraulic system to provide bending force of up to 175 tons, and automatically controls the movement of the slide (upper die) and back gauge through a CNC control system to achieve high-precision bending of metal sheets. It is mainly used for metal sheet processing in industries such as sheet metal processing, machinery manufacturing, automotive parts, building curtain walls, and electrical cabinets.

A typical CNC hydraulic bending machine consists of the following main components:

Usually constructed from welded steel plates that have undergone aging treatment, resulting in high structural rigidity, good stability, and the ability to withstand large bending forces.

The core power source, controlling the slide movement via proportional valves or servo hydraulics. A high-quality hydraulic system ensures smooth operation, fast response, and adjustable pressure.

The CNC system (such as DELEM, Cybelec, ESA, or SC EL) controls the movement of the slide axis (Y-axis) and back gauge axis (X/R/Z, etc.), allowing for preset programs, automatic positioning, and repeatable processing.

Driven by ball screws and linear guides, it precisely positions the sheet metal, improving bending accuracy and repeatability.

The upper and lower molds (V-shaped, U-shaped, etc.) can be quickly clamped for bending processing of different thicknesses, angles and shapes.

The CNC system, combined with a back gauge, ensures consistent angle and height during each processing operation, reducing human error.

The 175ton CNC press brake hydraulic system can bend thicker steel plates (e.g., 3–10 mm), making it suitable for medium-thick plate bending production.

Compared to traditional manual/semi-automatic bending machines, CNC control reduces positioning and repetitive adjustment time, improving production efficiency.

Various bending processes, such as V-bending, U-bending, and air bending, can be achieved by selecting different molds and programs.

When selecting a 175ton CNC hydraulic press brake, we recommend considering the following:

- Control system brand and number of axes: 6 axes or more for stronger production capacity (e.g., X/R/Z)

- Hydraulic system quality and response speed: Servo proportional valve systems offer greater stability

- Back gauge accuracy and drive method: Ball screw + linear guide for higher precision

- Safety features: Light curtain, safety doors, electrical safety certifications, etc.

- After-sales and maintenance support: Supply cycle of key components and spare parts, and technical support capabilities.