Shenchong W12-16×2000 is a four-roll hydraulic plate rolling machine in the W12 series, suitable for rolling (cylindrical, conical, arc-shaped, etc.) carbon steel, stainless steel, and other metal plates with a maximum thickness of approximately 16 mm and a maximum processing width of 2000 mm. The W12 4-roll plate rolling machine (16X2000MM) uses an upper roll as the main drive, with the lower and side rolls hydraulically lifted and their positions controlled by CNC/PLC. This allows for pre-bending of the plate ends and one-time forming without multiple plate flipping, making it suitable for processing boilers, containers, shipbuilding, pressure vessels, towers, and metal structural parts.

The W12 series is a hydraulically driven four-roll plate bending machine. The upper roll is the main drive, while the bottom and side rolls are hydraulically lifted/positioned, and it features end pre-bending functionality. End pre-bending and rolling can be completed in a single loading operation. Common specifications include W12-16×2000 (capable of rolling a maximum plate thickness of approximately 16 mm and a width of 2000 mm).

- Model: W12-16×2000

- Maximum Rolling Thickness: 16 mm (carbon steel, yield strength approximately 245 MPa)

- Maximum Processing Width: 2000 mm.

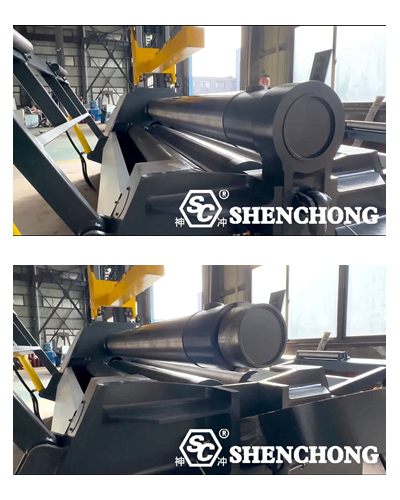

- Upper roller diameter: ≈ 300 mm

- Lower roller diameter: ≈ 270 mm

- Side roller diameter: ≈ 210 mm

- Main motor power: Approximately 11 kW (common configuration)

- Minimum winding diameter (reference): ≈ 600 mm (depending on plate thickness, material, and actual process parameters).

- Rolling speed: Commonly 3–5 m/min

- Drive method: Main drive of upper roller + hydraulic lifting and positioning of lower roller/side roller (often using gear transmission or a reduction gearbox to drive the lower roller)

- Control: PLC/digital display or CNC/handheld operator (with preset programs, automatic leveling, side roller position display, and template saving).

The upper roll (main drive) is located between the two lower rolls. The two lower rolls support the plate and provide rolling friction during rotation. The upper roll presses down, causing the plate to yield and gradually form a bend. The side rolls are used for pre-bending the plate ends or for auxiliary positioning (the W12 series has a pre-bending function).

The lifting of the lower rolls and side rolls is usually driven by hydraulic cylinders. Position is controlled by valve groups and feedback from sensors/encoders achieves precise positioning and automatic leveling.

The upper roll is driven by a motor via a reducer. The lower rolls obtain driving force through gear shaft meshing or couplings (slight differences between manufacturers).

Before rolling, the side rolls or upper roll can perform a pre-bending action, forming a small arc at the plate end to avoid opening and cracking, thus completing the end taper of the cylinder in one step.

Modern models are often equipped with a mobile human-machine interface or handheld controller. Saves the rolling program (diameter/length/plate thickness). Automatically calculates the side roller position and upper roller pressing process. Improves the accuracy and efficiency of repeated processing.

- One-Step Forming with Pre-Bending: Enables end pre-bending and rolling in a single loading operation. Reduces manual plate turning and secondary processing steps, increasing production capacity and yield.

- Excellent Forming Precision: Hydraulic position control + digital display/PLC programmed operation. Accurate repeatability and precise control over roll roundness and end gap.

- Compact Structure and Easy Operation: Main drive for the upper roller, hydraulic drive for - bottom and side roller lifting. Convenient maintenance.

Wide Applicability: Can roll various materials (carbon steel, low alloy steel, stainless steel, aluminum plates, etc., parameters adjusted according to thickness and yield strength).

Pressure vessels, boiler manufacturing, shipbuilding, petrochemical towers, pipe joints, wind turbine tower sections, metal structural components, process equipment housings, etc.

The W12 4-roll plate rolling machine 16×2000mmis suitable for processing barrels, cylinder sections, and curved components of medium thickness and width.

The W12-16×2000 four-roll plate bending machine is a mature four-roll plate bending machine designed for customers producing medium-thick plates (≤16mm) and medium-width plates (2000mm). Its advantages include one-time pre-bending forming, selecting levels of automation, and stable forming.

Key points to confirm during procurement: material type and yield strength (determining the actual rolling thickness), minimum roll diameter requirements, and whether loading/unloading/automation is needed.