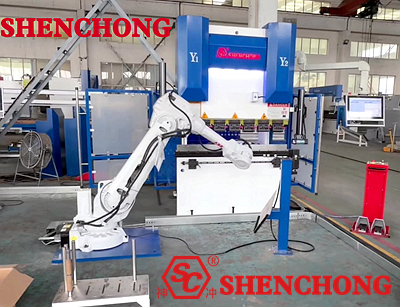

SHENCHONG Italy robotic bending unit deeply integrates a hybrid electric servo CNC press brake with robot ABB IRB 4600-60. Combined with an automatic gripping system, positioning table, and intelligent control software, it achieves fully automated sheet metal feeding, positioning, bending, flipping, and unloading. It is suitable for batch, high-precision, continuous production of small to medium-sized sheet metal parts.

- Typical Configuration

- Nominal Pressure: 80T

- Working Length: 1500mm

- Control System: DA58T

- Axis Control Type: 6+1

- Servo motor drives the oil pump, supplying power only during bending

- Energy consumption reduced by 50%

- Stable oil temperature

- High repeatability

- Low noise

- Suitable for long-term operation in automated production lines

- Maximum Payload: 60 kg

- Maximum Working Radius: 2.05 m

- Repeat Positioning Accuracy: ±0.05 mm

- Compact structure, small footprint, high operating speed

- Automatic sheet metal gripping

- Precisely feeds into the bending station

- Workpiece flipping and multi-process repositioning

- Automatic palletizing or conveying after bending

The IRB 4600 series is ideal for high-speed applications such as bending, stamping, and machine tool loading/unloading.

- Vacuum suction cup or mechanical gripper (adaptable to different sheet metals)

- Anti-slip and anti-deformation design ensures stability of thin sheets

- Automatic loading platform/stock hopper (optional)

- Flipping table, positioning table

- Safety fence + light curtain + emergency stop system

- Stable cycle time per piece

- 24-hour continuous operation

- 2-3 times more efficient than manual bending

- Eliminates human error

- High consistency in angles and dimensions

- Especially suitable for bulk orders

- Hybrid hydraulic structure significantly reduces energy consumption

- Low heat generation, long hydraulic system lifespan

- Long robot maintenance cycle, low failure rate

- One person can manage multiple bending units

- Alleviates the shortage of skilled bending workers

- Enhances factory automation and image

- Electrical cabinets and boxes (sheet metal parts)

- Appliance casings and metal housings

- Structural parts for engineering machinery

- Small and medium-sized parts with multiple bends

- Bulk repeat orders

SC hybrid electric CNC press brake machine paired with an ABB IRB 4600-60 six-axis industrial robot forms an integrated robotic bending unit, enabling fully automated production processes including automatic sheet metal feeding, precise positioning, continuous bending, and automatic unloading.

SHENCHONG Italy robotic bending unit is specifically designed for mass production of sheet metal parts, requiring high consistency and high cycle time, making it an ideal choice for upgrading traditional manual bending to intelligent manufacturing.