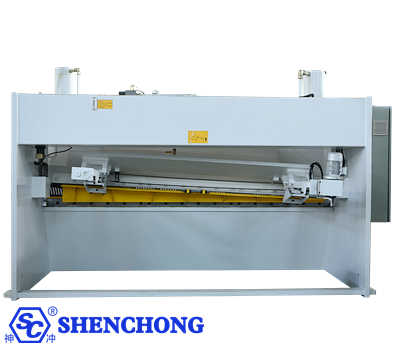

SHENCHONG 10mm metal plate shearing machine for sale is an industrial piece of equipment used for linearly shearing sheet metal such as steel, stainless steel, and aluminum plates with a thickness of ≤10 mm. Most are hydraulic guillotine shear machines, which achieve precise shearing through the linear reciprocating motion of upper and lower blades, offering advantages such as high rigidity, high cut quality, and high-speed operation.

Material Types | Shearing thickness (reference) | Notes |

Q235 Plain Carbon Steel | ≤10 mm | Standard parameters are often based on this material |

Q345 High-Strength Steel | ≤8 mm | Higher strength requires a reduction of approximately 20% |

Stainless Steel (SUS304) | ≤6–8 mm | Aluminum requires a reduction of approximately 20-30% |

Aluminum Plate/Aluminum Alloy | ≤12–14 mm | Aluminum is softer; thickness can be increased appropriately |

The material of the blade and the adjustment of the blade gap have a significant impact on actual production capacity.

The following are the mainstream specifications for common 10 mm hydraulic guillotine shear machines (for selection reference):

- Maximum shearing thickness: 10 mm (Q235)

- Maximum shearing width: 2500 / 3200 / 4000 mm (common 3m and 4m)

- Hydraulic guillotine

- Linear reciprocating upper blade holder

- Adjustable shearing angle (e.g., 0.5–2°)

- Small deformation, high precision, wide versatility

- Stroke: 600 mm (optional 800mm, 1m)

- Precision: ±0.10 mm (CNC servo)

- Optional servo motor and ball screw

- 6CrW2Si or Cr12MoV

- High wear-resistant blades can be selected according to the material

- High-pressure hydraulic pump (usually a well-known domestic brand or German brand) Rexroth - Integrated Hydraulic Control Valve Manifold: Low noise, high stability

- Shearing Angle: Automatically adjustable

- Blade Gap Adjustment: Manual/Electric/CNC

- Shearing Straightness: ≤0.05–0.1 mm/m

The 10mm metal plate shearing machine mainly consists of a frame, blade holder, worktable, hydraulic system, electrical control system, back gauge, blade adjustment mechanism, pressing device, and safety devices. These structures work together to complete the shearing action of the metal sheet.

- Frame: The frame is the main load-bearing structure of the shearing machine, welded from high-strength steel plates and stress-relieved.

- Blade Holder: The upper/lower blade holder is the clamping and shearing mechanism for the upper blade and is the core mechanical component of plate shearing machine.

- Worktable: Used to support the sheet metal and complete the shearing action, it is the machine's operating platform. It has built-in ball bearings or roller bearings to reduce scratches on the sheet metal and facilitate its movement. A scale or positioning stop is provided at the front to assist the operator in positioning the sheet metal.

- Blade and Gap Adjustment Device: Ensures that different materials are sheared at the optimal gap. The upper and lower blades are generally made of Cr12MoV/9CrSi.

- Hydraulic System: Provides the shearing power, including cylinders, hydraulic pump station, valve group, and pipelines. Typically composed of multiple sets of hydraulic pressure cylinders and pressure feet.

- Pressure device: Responsible for firmly pressing the metal sheet before shearing, preventing sheet movement or vibration.

- Back gauge mechanism (NC/servo): Used for positioning the shearing dimension, a key component for fixed-length cutting. Employs ball screw, linear guide, or rack and pinion transmission for high positioning accuracy.

- Front and rear support system: Used to support long sheets, preventing sagging and deformation.

- Shearing angle adjustment mechanism: Reduces shearing force and improves cut quality by changing the shearing angle.

- Safety protection system: Feed guardrail, front guardrail, side guardrails, emergency stop button.

- CNC control system: E21S/Delem DAC 360T/ELGO P40

- High Shearing Quality: Excellent straightness and minimal deformation

- Stable Structure: Integral welded frame, high rigidity

- Intelligent Operation: Optional NC/CNC blade gap and shearing angle

- Suitable for various materials: Plain steel, stainless steel, aluminum plate

- High Reliability: Suitable hydraulic system and blades ensure long service life

- High Safety: Optional light curtain protection, guardrail protection, emergency stop system

Adopting an integral welded steel structure (Q345 or higher strength steel), subjected to vibration aging/tempering treatment, the frame has high rigidity and is not easily deformed.

Even force transmission during shearing, maintaining stability even when shearing 10 mm plates for extended periods.

Dual cylinders synchronously drive the shearing beam, ensuring smooth operation.

The hydraulic pump station uses a low-noise, high-efficiency pump with low temperature rise and high reliability.

Standard configuration includes a pressure relief valve and temperature control protection to ensure stable oil pressure and prevent overload damage.

The shearing beam (blade holder) adopts an inclined design, reducing sheet metal deformation and improving the quality of the sheared end face.

Shearing straightness can reach ≤ 0.05 mm/m (depending on brand and configuration).

The blades are made of high-quality Cr12MoV or 9CrSi material, offering good wear resistance and long service life.

Configuration includes manual, electric, or CNC blade gap adjustment.

The gap can be quickly adjusted according to material type (steel, stainless steel, aluminum, etc.) to ensure shearing quality.

Supports display accuracy typically 0.1 mm or higher.

The shearing angle can be adjusted within the range of 0.5° ~ 2° (slightly different between models).

The angle adjustment system reduces distortion and deformation during thick plate shearing, improving finished product quality.

Employs ball screw or rack and pinion transmission for fast and accurate positioning. The stroke is typically 600 mm or 800 mm, with longer strokes available.

Control system options:

- E21S NC (basic CNC)

- ELGO P40 (mid-range)

- Delem DAC series (high-end)

Optional automation components include:

- Pneumatic/mechanical sheet metal support

- Automatic feeding system

- Servo feeding + automatic length cutting

- Robot loading/unloading (suitable for mass production)

- Laser positioning or projection line assisted cutting line

These features significantly improve throughput and consistency.

Plate Shearing Automatic Production Line

Standard features include front guardrail, side guardrail, and emergency stop button.

Optional features:

- Light grating safety protection (prevents crossing through the shearing area)

- Foot pedal linkage to prevent accidental activation

- Hydraulic pressure monitoring and alarm system

Ensuring operator safety in compliance with CE/ISO standards.

Clear layout of the hydraulic system and control circuit, easy to maintain.

The blade can be used on all four sides, reducing replacement costs.

Before making a specific selection, clarify several key dimensions that will strongly influence equipment model selection:

Sheet Material and Strength: Differences in tensile strength and ductility of materials such as ordinary steel, stainless steel, and aluminum will affect shearing force, blade clearance, and frame rigidity.

Sheet Thickness and Width: For "10 mm metal sheet," clarify whether it refers to the maximum thickness of 10 mm or the standard working thickness, and the sheet length/width (shearing length).

Precision Requirements: Determine if high precision is required for shearing straightness, blade burr control, and angle control. Different applications (e.g., subsequent bending, welding, or direct shipment) have different precision requirements.

Production Volume/Frequency: Is it for occasional shearing of a few sheets, or large-scale daily production? And is automation (back gauge, front feed, etc.) necessary?

Control System: Is a simple NC (e.g., E21S) sufficient? Or is a more advanced CNC/servo control system required?

Blade and Clearance Adjustment: Different materials require different blade materials and clearance settings.

Safety and maintenance: Whether a light curtain, emergency stop, ease of maintenance, and after-sales support are required.

- Hydraulic Oil: Oil level, contamination, temperature

- Lubrication Points: Guide rails/slider/back gauge screw

- Safety Device Inspection: Emergency stop, light curtain/safety railing

- Electrical System: Loose wiring, switch status

- Replace hydraulic filter

- Check blade wear/re-sharpen/replace blades

- Check screw and guide rail clearance

- Check oil pump operation (pressure, noise)

- Comprehensive hydraulic system inspection (leakage)

- Hydraulic oil change (according to manufacturer's recommended schedule)

- Frame inspection (welds, deformation)

- Control system software/hardware upgrade (if DAC/advanced CNC system is available)