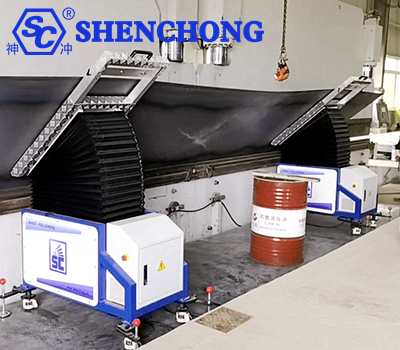

SHENCHONG DLSD20 bending follower for sale is an intelligent auxiliary device used in sheet metal bending processes for supporting and automatically following large sheet metal parts. It is typically used in conjunction with CNC press brake machines. It primarily addresses problems encountered in large sheet metal processing, such as difficulty in manual support, sheet metal sagging, inaccurate bending angles, and surface scratches.

The SHENCHONG DLSD20 bending follower features automatic support, intelligent follow-up, height adjustment, and scratch protection, significantly reducing worker labor intensity and improving bending efficiency for complex sheet metal parts. Its follow-up angle range is wide, and its operation is smooth, making it suitable for press brakes of various sizes from 40 tons to 300 tons. It is highly compatible with stainless steel, aluminum sheets, and large-format sheet metal.

Provides stable support for large-format, heavy sheet metal, preventing sagging due to weight.

Through a servo system that synchronizes with the bending machine, the support table automatically follows the bending trajectory of the sheet metal, maintaining consistent angles.

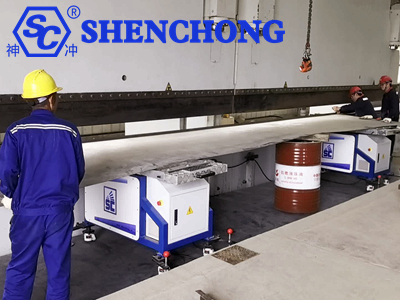

Significantly reduces the need for manual sheet metal support; one person can operate large-size sheets.

The support table typically uses a wear-resistant layer or rollers to prevent scratches on materials such as stainless steel and aluminum sheets.

Bending consistency and repeatability are improved through follow-up control and angle compensation.

- Servo motor + precision lead screw (drives lifting)

- Guide rail slider mechanism

- Supporting table

- Follow-up angle sensor

- Control system (interconnected with bending machine)

- Adjustable support arm

- Rollers/nylon pad (scratch-resistant)

- Bending of large sheet metal parts

- Chassis and cabinet manufacturing

- Bending of kitchenware sheet materials

- Processing of architectural decorative panels

- Electrical control cabinet doors

- Bending of high-rebound materials (such as stainless steel and aluminum)

Especially suitable for: long plates, thin plates, large plates, and materials prone to sagging or deformation.

Prevents sheet metal sagging that could cause angle changes or indentations.

Reduces the risk of manual sheet metal support and prevents sudden slippage.

Makes large sheet metal bending possible with a single operator, saving manpower.

Reduces the additional pressure on the dies caused by sheet metal imbalance forces.

The SHENCHONG DLSD20 bending follower for sale is an intelligent auxiliary support device applied to the front end of a CNC plate bending machine. It primarily solves the problems of sagging, deformation, and difficulty in manual support during the bending of large, long, and thin plates. The equipment uses servo drive and synchronous control with the press brake. Through a material support table, it achieves automatic following of the sheet metal during the bending process, effectively improving bending accuracy and processing stability.

With its compact structure, simple operation, and low maintenance, SHENCHONG DLSD20 follower has become a key auxiliary system for improving bending quality in modern sheet metal processing. It not only improves bending consistency and product qualification rate but also enhances production safety and provides a reliable guarantee for enterprises to achieve automated and high-efficiency processing.