The production cycle in robotic bending (automated bending systems) is one of the core metrics for measuring system efficiency. It refers to the total time required to complete the entire process of a workpiece, from material handling to positioning, bending, and unloading.

Generally, the production cycle is the time it takes for a company to transform inventory into finished goods.

Shortening the production cycle time is highly beneficial for companies. This dynamic means that the company is reducing the time required to transform its average inventory into finished goods. Shorter operating cycles can reduce the share of fixed costs in every dollar of finished goods and services provided.

The cycle time of a production operation refers to the time required in a workplace from the start to the completion of an operation or function, work, or task. Because production tasks differ, and the workplaces where these tasks are completed also differ, the components of cycle time directly depend on the nature of the tasks that need to be completed in the workplace.

Cycle time analysis is any method of collecting and analyzing process time data to improve the entire process or system. Cycle time determines the productivity of robotic bending operations. Productivity largely depends on workplace management. Effective operation is a prerequisite created by selecting the right equipment and designing the layout.

It typically consists of the following time-consuming steps:

* Grab the sheet metal from the rack/bin.

* Determine the position (visual positioning can increase time).

* Grab and move the sheet metal to the bending machine's positioning position.

* Place the sheet metal in front of the bending machine's die.

* Adjust the position (aligner, positioning pins).

* The robot releases its grip and moves away.

* The bending machine presses the material.

* The slider descends to complete the bending.

* The slider rises back to its original position.

* If the product requires multiple bends, the time for each bend needs to be added together.

* Randomly coordinate with the bending machine to support the material.

* During multi-sided bending, the robot flips the part.

* Change the gripping posture.

* Remove the bent part from the press brake bending machine.

* Place it in the material box or conveyor belt.

* The robot returns to its initial position.

Production cycle = Material pick-up + Material loading + Bending passes + Flipping/gripper changing + Unloading + Idle time

Cycle Time = 4s (material pick-up) + 3s (positioning) + 5s × 4 bending passes (20s) + 6s (flipping) + 4s (unloading) = 37s/piece

In today's highly competitive sheet metal manufacturing industry, efficiency is paramount. Business owners, engineers, and purchasing managers are constantly seeking ways to increase production capacity and shorten delivery times. In this process, robotic bending technology has emerged as a key component in achieving smart manufacturing.

The core metric for measuring the efficiency of a robotic bending system is the "production cycle." So, what factors affect the production cycle in robotic bending?

*Speed, Load, Gripper Weight

*Path Optimization Degree

*Does frequent gripper changing require?

*Is there a rapid flipping mechanism?

*Slider Speed

*Return Speed

*Large parts require slow follow-up

*The higher the number of bends, the longer the cycle time.

*Fewer unnecessary movements result in a faster cycle time.

Workpiece Dimensions and Number of Bending Steps | Typical production cycle time |

Small parts (2-4 bends) | 18-25 seconds/piece |

Medium parts (4-8 bends) | 30-45 seconds/piece |

Large parts (8-15 bends) | 60-120 seconds/piece |

The production cycle of robotic bending is the complete processing time "from picking up the sheet material to unloading the finished product", which is a key indicator for judging the efficiency of bending automation.

The production cycle of robotic bending is the complete processing time "from picking up the sheet metal to unloading the finished product," and it is a key indicator for judging the efficiency of bending automation. How should factories optimize the production cycle of sheet metal parts to maximize efficiency?

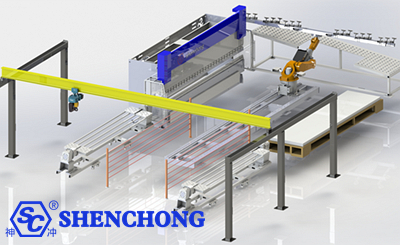

Select fully automated bending units that integrate loading, robotic bending, unloading, and stacking. This allows for seamless connection between various processes, eliminating time wasted due to human intervention.

Use professional offline programming software for robotic bending. All programming and process simulation can be completed on a computer, achieving "offline programming, online production." This significantly reduces robot downtime for programming and allows for pre-optimization of motion paths.

Use multi-V-groove dies to reduce die changeover frequency.

Reasonably increase bending speed while ensuring quality.

Cooperate with die suppliers to select lightweight, quick-change die solutions.

Utilize the robot's data acquisition function to record the time of each action stage in detail. Through data analysis, identify bottleneck processes and implement targeted improvements. For example, if repositioning time is found to be excessively high, the robot's grasping posture and motion trajectory can be optimized.

Regularly maintain robots, bending machines, and auxiliary equipment to ensure they are always in optimal performance condition. Avoid production interruptions and cycle delays caused by unexpected malfunctions.

The production cycle in robotic bending is a "thermometer" for measuring the overall performance of a system. It's not just a simple number, but a concentrated reflection of design, technology, equipment, and management.

A deep understanding of its components, and continuous, meticulous management and optimization, are the only way for sheet metal manufacturing companies to move from "manufacturing" to "intelligent manufacturing" and maintain a strong competitive edge in the market. By embracing automation, digitalization, and intelligent solutions, companies can compress production cycles to their limits, thereby achieving faster response times, lower costs, and higher customer satisfaction.