Handling robots are industrial robots that can perform automated handling operations. The earliest handling robots appeared in the United States in 1960, and the Versatran and Unimate robots were first used in handling operations. Handling is the holding of a workpiece with a piece of equipment, and it is moving from one machining location to another. The handling robot can be installed with different end effectors to complete the handling of workpieces of various shapes and states, which greatly reduces the heavy manual labor of human beings. There are more than 100,000 handling robots used in the world, which are widely used in the automatic handling of machine tool loading and unloading, automatic production lines of stamping machines, automatic assembly lines, palletizing and handling, and containers. Some developed countries have formulated the maximum limit for manual handling, and the excess must be done by handling robots.

With the advancement of technology, industries that previously required manual processing and manufacturing have begun to shift to automated technology. As a kind of high-tech automatic production equipment developed in recent decades, industrial robots and manipulators play an important role in the field of modern manufacturing technology. There are multiple degrees of freedom that can be used to move objects to accomplish work in various environments.

Manipulators are widely used in industrial production. Whether it is a single machine or a combined machine tool, as well as an automatic production line, the manipulator can be used to complete the pick and place of workpieces. The control of the manipulator is mainly to identify the position, control the movement direction and judge whether the material exists. Its task is to transport workpieces or items on conveyor belt A to conveyor belt B. The handling manipulator is controlled by PLC + touch screen + servo motor. It adopts a frame structure that takes up less space and has a large production capacity. The palletizing method can be programmed by teaching, and the computer can store 100 sets of palletizing plans.

Industrial manipulators have developed into high-tech automated production equipment in recent years, and are a type of industrial robots. The characteristic is that it can be programmed to complete a variety of expected tasks.

- Ensure sufficient clamping force.

- There should be a minimum opening and closing angle between the fingers.

- Precise positioning of the workpiece in the whole process.

- It should have sufficient strength and rigidity.

- The requirements of the grabbed object should be considered.

- Simple structure and weight control.

- Flexible and reliable, good sealing.

- Pipeline layout and lubrication/maintenance/adjustment.

- Influence of degrees of freedom and working environment.

- Ensure the stiffness of the arm.

- Good orientation.

- The partial gravity moment should be small.

- Smooth movement and precise positioning.

Handling robot is a high-tech emerging in the field of modern automatic control. The handling robot can be installed with different end effectors to complete the handling of workpieces of various shapes and states, greatly reducing labor costs.

- It can partially replace manual operation.

- It can complete the transfer and loading and unloading of workpieces according to the requirements of the production process, following certain procedures, time and positions.

- It can operate the necessary equipment for welding and assembly, thereby greatly improving the working conditions of workers, significantly improving labor productivity, and accelerating the pace of industrial production mechanization and automation.

In general, handling robots can be programmed to complete a variety of expected tasks, and have the respective advantages of humans and machines in their structure and performance, especially artificial intelligence and adaptability.

Therefore, industrial handling robots have attracted the attention of many countries, and a lot of manpower and material resources have been invested in research and application. Especially in high temperature, high pressure, dust, noise and radioactive and polluted occasions, it is more widely used.

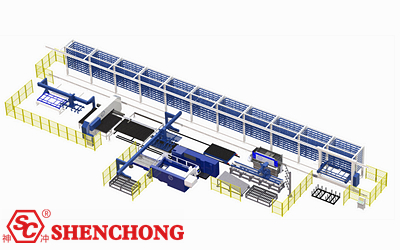

Application scenarios: At present, handling robots are widely used in the automatic handling of machine tool loading and unloading, automatic production lines of stamping machines, automatic assembly lines, palletizing and handling, and containers. Mainly used in industrial scenarios such as packaging, parts assembly, printing, handling, etc., so that the logistics solution can achieve 6 "correct" functions, namely correct goods, correct quantity, correct location, correct quality, correct time correct price; technically realized: item identification, location tracking, item traceability, item monitoring, real-time response.

Customer benefits: high safety, high operating efficiency, low input cost, low management difficulty, high reliability, reduced product damage, better flexibility and scalability.