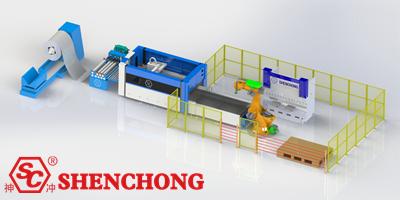

The high-speed automatic cable tray production line is composed of an uncoiler, a leveling machine, a rotating laser cutting machine, a press brake rolling push feeding mechanism, a fully automatic CNC press brake, and a stacking robot.

Cable tray production automation equipment is an advanced production equipment. By adopting automation technology and cutting technology, various specifications of steel can be accurately cut into the required dimensions using this equipment. On the premise of ensuring high precision, its production efficiency is greatly improved.

- The uncoiling and leveling machine is mainly used for thin plates below 3mm.

- Laser cutting machines are used for cutting holes and cutting.

- The pushing mechanism of the press brake is used for feeding plates onto the bending machine.

- The automatic press brake machine is used to continuously bend four sides and then push them sideways to the finished product position.

- The palletizing robot performs palletizing.

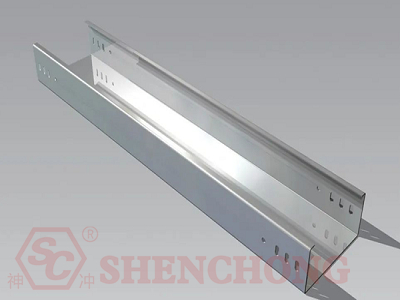

Slot type cable tray is a fully enclosed cable tray suitable for laying computer cables, communication cables, thermocouple cables, and other highly sensitive system control cables. The shielding interference of control cables and the protection of cables in heavily corrosive environments have good effects.

The surface treatment of trough type cable trays can be divided into: electrostatic spraying, hot-dip galvanizing, hot-dip galvanizing, etc., which can be used in different environments. Special anti-corrosion treatment should be carried out in heavily corrosive environments.

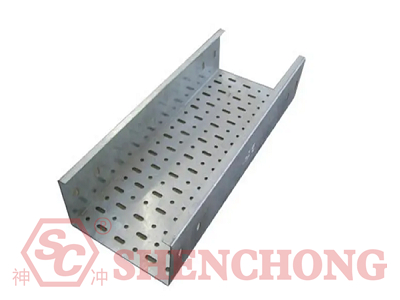

Tray type cable trays are mainly used in petroleum, chemical, light industry, television, telecommunications and other engineering projects, with advantages such as light weight, large load, beautiful appearance, simple structure, and convenient installation. Suitable for both the laying of power cables and the laying of control cables.

The surface treatment of tray type cable trays can be divided into: electrostatic spraying, hot-dip galvanizing, hot-dip galvanizing, etc., which can be used in different environments. Special anti-corrosion treatment should be carried out in heavily corrosive environments.

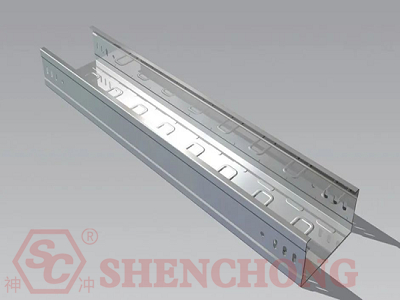

The stepped cable tray has the advantages of light weight, simple structure, low cost, high strength, unique design, convenient installation, good heat dissipation, and breathability. Suitable for laying cables with larger diameters and high and low voltage power cables.

The surface treatment of stepped cable trays can be divided into: electrostatic spraying, hot-dip galvanizing, hot-dip galvanizing, etc., which can be used in different environments. Special anti-corrosion treatment should be carried out in heavily corrosive environments.

The energy-saving bridge adopts the technology of overall reinforcement ribs, effectively enhancing the load capacity and deformation resistance of the bridge. Due to the enhanced structural strength, the thickness of steel plates for bridges of the same specification can be correspondingly reduced while maintaining the same load capacity, reducing the cost of construction.

At the same time, the concave and convex corrugated ribs have expanded the heat dissipation area of the bridge, and a heat dissipation structure for exchanging cold and hot air from top to bottom has been designed. It reduces the resistivity and resistance value of the cable, improves the utilization rate of electrical energy, and achieves energy-saving effects.

The high-speed automatic cable tray production line is a molding equipment used for producing cable trays. Convenient size adjustment. Fast speed. One hour can produce 100 wire trays ranging from two to four meters. If automatic packaging is required, it can also be connected to the automatic packaging production line. Wuxi Shenchong can customize and plan fully automated production lines for customers. No human intervention is required during the production process, and there is no need for complex manual labor throughout the entire production process.

Case review: