Many bending machine users will purchase CNC grooving machine to match better bending effect. But do you really know how to operate sheet metal v grooving machine safely? We will tell you the correct operation rules and some usage suggestions. Please read on patiently!

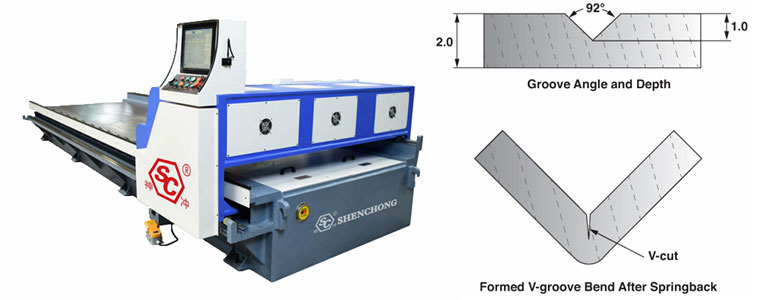

The CNC grooving machine is used before bending ordinary steel plate, aluminum plate, copper plate and composite plate. It performs a certain depth of V-grooving on the bending part of the plate.

The work piece made by grooving bending process has the following advantages:

– Small bending fillet radius

– No obvious color change

– Small bending force

– Smaller edge straightness error of narrow and long work piece bending

Then, in the ordinary press brake, we can also use the universal die to bend the sheet metal with complex shape.

The groove depth of metal plate with different material and thickness is different.

If the groove is too shallow, the subsequent bending effect will not be obvious. If the V-groove is too deep, it is easy to affect the structural strength of the work piece.

Therefore, it is very important for users to determine a suitable v-grooving depth before starting work.

Take the grooving of the stainless steel plate of the elevator as an example for a reference:

The thickness of the remaining plate after grooving is generally 40% to 50% of the original board.

– When the plate thickness is 1.0 mm, the groove depth is 0.5 mm and the residual material thickness is 0.5 mm.

– When the plate thickness is 1.2mm, the grooving depth is 0.7mm and the residual material thickness is 0.5mm.

– When the plate thickness is 1.5mm, the grooving depth is 0.9mm and the residual material thickness is 0.6mm.

– When the plate thickness is 2.0 mm, the grooving depth is 1.2 mm and the residual material thickness is 0.8 mm.

Although the spring back of metal sheet after grooving process is greatly reduced, it still exists.

Therefore, when making the V-shaped groove, we should flexibly slot according to the bending angle.

Once again, we take stainless steel sheet as an example:

– The slotting angle of V groove is 1 ° to 2 ° larger than that of bending.

– For a work piece with 90 ° forming angle, the V groove machine slotting angle is generally 92 °.

In this way, we can avoid efficiently the angle error caused by spring back.

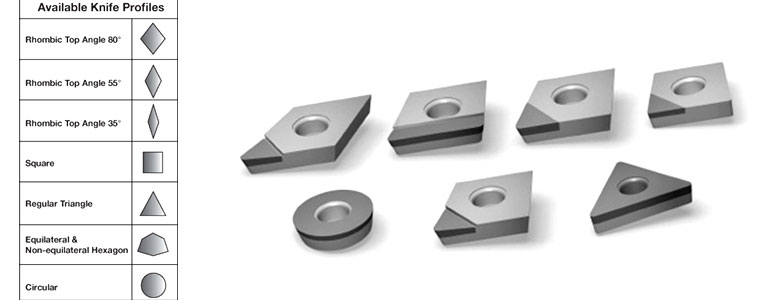

CNC sheet metal grooving machine tool knife types are mainly divided into:

– Diamond top angle groove cutter

– Square groove cutter

– Triangular groove cutter

– Round groove cutter and so on

Before making groove, you should choose the right tool according to the different shape and angle of V-grooving. When making the ordinary V-groove, the angle of cutter should be less than that of V-groove.

For example:

– When the V-groove angle is 45 ° to 60 °, we should choose the slotting cutter with diamond top angle of 35 °.

– When the angle is between 60 ° and 80 °, we should choose the regular triangle slotting cutter.

– When the angle is 80 ° to 90 °, we should choose the slotting cutter with diamond top angle of 80 °.

– When the angle is greater than 90 °, we should choose the square slotting cutter.

– When cutting round groove, we choose circular slotting cutter.

In order to ensure the safety of operators and equipment of numerical control V groove machine, we specially organize the latest safety operation regulations.

Applicable to all CNC v grooving machine for sheet metal.

– Operators should read the operation instruction carefully and operate strictly according to the regulations.

– Team leader should supervise the operator to operate the machine correctly.

– CNC groove machine should be maintained and operated by special personnel.

– Operators must be trained by professional departments. Only after passing the examination and obtaining the certificate can the workers operate independently.

– Before operation, personnel should wear long sleeve work clothes to prevent being injured by splashing groove debris.

– Workers must wear gloves when loading and unloading sheet metal.

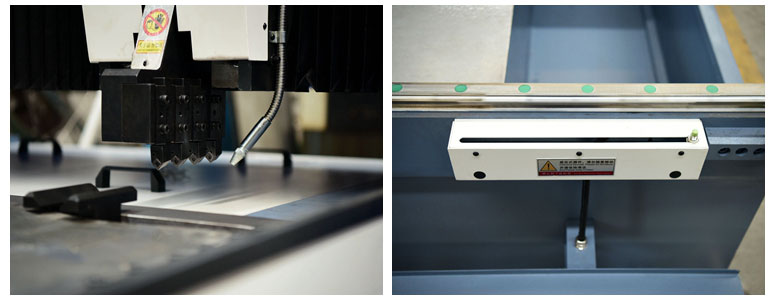

– Before starting the CNC sheet metal v grooving machine, check whether the machine table is clean. In particular, there must be no residue between the clamp and the table top.

– Origin reset: align the origin first after starting.

– During operation, check whether the work piece meets the process requirements according to the drawing. Input the size and depth of the work piece correctly.

– When loading small metal plate, operators should remember to handle with care.

– Before loading, clean the machine table and discharge table. No gouging wire and other debris shall be left.

– Before starting operation, check whether the sheet metal is pushed to the original point.

– During the operation, the staff shall not extend the head and any part of the body into the moving area of the machine to prevent being hit by the machine.

– Do not place the air gun and hands under the fixed clamp.

– In case of machine collision or sheet metal collision accident, it is necessary to stop the operation first and then reset the origin. To prevent the origin running in collision.

– After the grooving is completed, the metal sheet shall be gently handled and placed at the designated position to prevent the work piece from being scratched artificially.

– After operation, carry out daily maintenance on the sheet metal CNC grooving machine.

– Cut off the power supply and clean the work site.