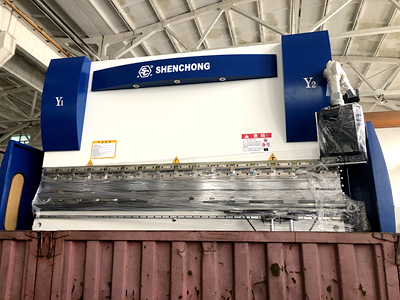

The textile equipment factory ordered a CNC press brake from us for the manufacturing and processing of textile machinery. It has been loaded and shipped to the customer's factory and the installation and commissioning work has been completed.

Textile machinery is a general term for various mechanical equipment that processes natural fibers or chemical fibers into required textiles. Textile machinery in a broad sense also includes chemical machinery that produces chemical fibers. Textile machinery is the production means and material basis of the textile industry. Its technical level, quality and manufacturing cost are directly related to the development of the textile industry.

Textile Machinery Manufacturing CNC Press Brake Model:

- WEK electro-hydraulic series

- 125Ton 3200mm

- ESA S630 CNC system

- 4+1 axis

Current situation of textile machinery manufacturing industry:

The textile machinery manufacturing industry is divided into two categories: one type manufactures the entire machine, and the other type manufactures special spare parts (such as spindles, cradle, steel rings, travelers, knitting needles, card clothing, healds, warp stoppers). tablets, etc.).

The special equipment of a textile machinery factory that manufactures a complete set accounts for a small proportion of the entire factory equipment. Therefore, under certain conditions, the variety can be changed to produce other machinery. The proportion of special equipment and special assembly lines in factories that manufacture special spare parts is relatively large (especially knitting needles and card clothing), and it is difficult to change varieties.

Among various types of processing work, the proportion of casters is gradually shrinking, while the proportion of cold stamping, grinding, electroplating, polishing, etc. is gradually increasing. CNC machine tools and multi-station automatic machine tools partially replace special-purpose machine tools, making production more adaptable and flexible. For metal parts in textile machinery, we need to use bending machines, shearing machines, punching machines and other equipment for processing.

Textile machinery is highly technological. The structure is complex and has many parts. They all need to be pre-assembled or partially assembled before leaving the factory. Then conduct production testing or partial production testing to ensure that the machine quality meets the requirements. Textile machinery factories all have well-equipped testing departments.

There are many types of parts for textile machinery. The processing procedures of parts are many and varied. If a factory produces multiple machines at the same time, it is necessary to properly arrange the production rhythm and connection of parts to ensure that the variety and quantity of parts required for the assembly of the entire machine can be provided on the assembly line as scheduled. The modern textile machinery industry mostly uses new management tools and methods such as computers and systems engineering to manage enterprises.