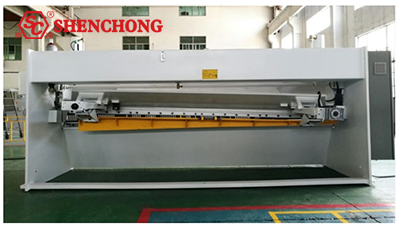

- Max. cutting thickness of plate: 6mm

- Max. cutting width of plate: 4000mm

- Cutting angle(adjustable): 0.5°-2.5°

- Cutting linear accuracy: ±0.05mm/M

- Stroke frequency: 8-30 times/min

- Max. distance of back gauge: 750mm

- Back gauge repeat positioning accuracy: ±0.05

- Back gauge any positioning accuracy: ±0.08

- Throat depth: 80

- Motor power: 7.5kw

- Overall Dimensions: 4650x1840x2100mm

- Weight: 8.8 Tons

1. CNC Controller go-to programmable hardened screw back-gauge 750mm travel with fine adjustment.

2. Adjustable hydraulic variable blade rake system via control panel 0.5˚- 2.5˚.

3. Rapid blade gap adjustment.

4. Emergency stops fitted on both ends of machine for additional safety.

5. Individual hydraulic hold downs with nylon pads.

6. Shadow line lighting allows operator to quickly see the cut line.

7. Swing away back-gauge function for cutting long sheets.

8. 4-edge quality 6CrW2Si blades.

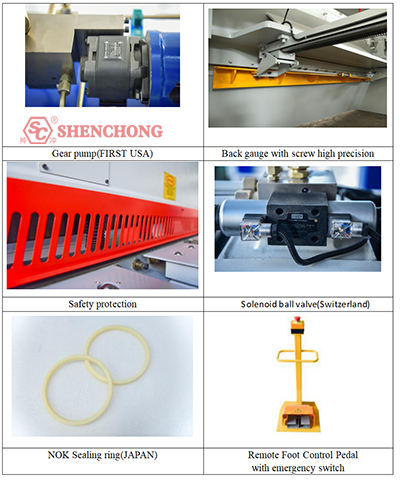

9. FIRST hydraulic valves.

10. Telemecanique electrical components(Schneider).

11. Transfer balls on table & support arms.

12. Support arms and squaring arms.

13. Stroke counter and short stroke adjustment.

14. Sliding chute with ball transfers inserts for cut pieces.

15. Two safety photo electric light beams on rear guarding.

1. Hydraulic guillotine structures.

2. Clip-and- sleeve system.

3. Automatic blade clearance adjustment controlled by CNC controller

4. Cutting angle adjustment,back-gauge driven by motor and display in CNC system

5. Blades material 6CrW2Si

6. Safe pedal with emergency button.

7. Hydraulic system: FIRST.

8. Motor: Chinese famous brand

9. Pump: FIRST, USA

10. NOK Japan layer seals for main cylinders.

11. Schneider main electrics.

12. Light alignment device

13. Electrical cabinet with ABB switch power outage.

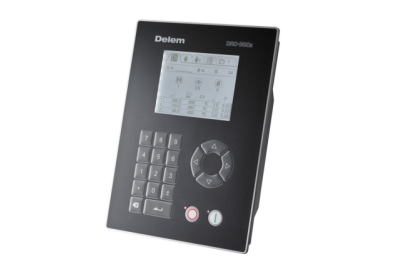

- Panel based housing

- Bright LCD screen

- Back / front gauge control

- Retract function

- Cutting angle and gap control

- Stroke length limitation

- Manual movement of all axes

- Force control

- Sheet thickness measurement

- RTS, Return to Sender function

- Second servo axis (DAC-362s)

- Sheet support

Standard

- 4.7” monochrome LCD

- Program memory for 100

programs

- Up to 25 steps per program

General

- Program library

- Millimetres / inches selection

- Power-down memorisation

- Machine hour counter

- Stroke counter

Axis

- Stroke control

- Gap control

- Angle control

- Back/front gauge control

dual gauge control (DAC-362s)

- Stroke 0 - 9,999.99 mm.

- Retract 0 - 9,999.99 mm.

- Correction -9.99 - 9.99 mm.

- Retract programmable

- Simultaneous axes movement

- Manual movement of axes

As a top hydraulic guillotine shearing machine manufacturer, Shenchong always focus on customers' satisfaction.

- We will arrange for engineers and installers to go to the site for installation, commissioning and training, which is about 3 days. Or you can arrange for people to come and study.

- The warranty period of the machine is 13 months, including one month in shipping.

- If there is any problem, we will first check the machine problem through video and guide the repair. If it still cannot be solved, an employee will be sent to the site for repair.

- During the warranty period, non-human damage, parts damage shall be responsible by the seller.