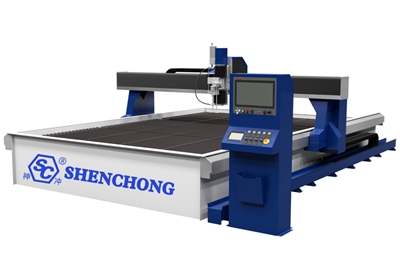

A waterjet cutting machine is a device that uses high-pressure water to cut materials. By adding abrasives (such as corundum) to the water, it can cut high-hardness materials such as metal, stone, glass, and ceramics. The key to using a water jet cutter correctly is safety, standardization, and proper maintenance. The following is a detailed step-by-step guide to help you use a water jet cutter correctly, efficiently, and safely.

Goggles, protective earmuffs, anti-cut gloves, non-slip safety shoes.

Check whether the water source is sufficient and whether the oil level of the high-pressure pump is normal.

Check whether the abrasive system is unobstructed and whether there is any blockage.

Check whether the nozzle and gem are intact and whether there is any wear or damage.

Use a clamp or a pressure plate to firmly fix the material on the workbench to prevent it from moving during cutting.

Import CAD drawings (usually in DXF format) into the control system.

Set parameters such as path, cutting speed, water pressure, abrasive flow rate, etc.

Manually move the cutting head, align the nozzle with the cutting starting point of the material, and set it to zero.

First perform a "dry run" to observe whether the path is correct to avoid miscutting or collision.

Start the high-pressure pump.

Turn on the abrasive system.

Start the cutting program and perform automatic cutting.

Observe the water pressure, nozzle operation and cutting status in real time to ensure that there are no abnormalities.

It is strictly forbidden to touch the working area with your hands, even when paused.

Monitor the water pressure and abrasive flow, and immediately stop processing if fluctuations are found.

Observe the cutting effect. If there is any incomplete cutting or deviation, stop checking immediately.

Pause the cutting program.

Turn off the high-pressure pump and slowly release the pressure.

Turn off the abrasive system and cooling system.

Turn off the CNC system and main power supply.

Clean the working area, recycle the residual material, and clean the abrasive.

Item | Recommended settings | Tips |

Water pressure | 3000~4000 bar (common industrial water jet) | The higher the pressure, the faster the cutting speed, but the greater the wear; use high pressure for thick materials |

Abrasive flow rate | 200~500 g/min | The thicker the material, the more abrasive should be used, but too much will clog the mixing tube |

Cutting speed | 10~100 mm/min (depending on the material) | Too fast will not cut through, too slow will cause the material to overheat or break the edge |

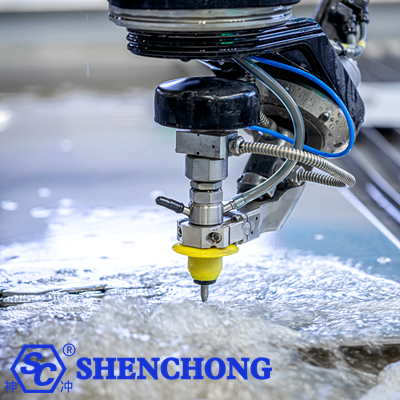

Distance between nozzle and workpiece | 1~2 mm | Too high will lose concentration, too low may collide or damage the nozzle |

Material Type | Tips |

Stainless steel/carbon steel | Use medium water pressure + high abrasive flow to avoid edge hardening |

Glass | Use a small hole to penetrate before cutting to reduce the chance of cracks |

Ceramic/stone | Reduce cutting speed to prevent edge collapse |

Aluminum/copper | Because the material is soft, the speed can be fast and the abrasive can be slightly reduced |

Composite materials (such as carbon fiber) | It is recommended to use fine abrasive and reduce the heat affected area |

Prevent program errors or nozzles from hitting the workpiece.

Use the "dry run" function to confirm whether the trajectory is reasonable.

Long-term continuous cutting is prone to overheating or system overload, so it is recommended to run in segments.

After the nozzle, gemstone, seal ring, etc. are worn out, the water pressure will drop and the cutting seam will become wider.

Avoid the starting point directly perforating the key position of the part to protect the integrity of the finished product edge.

Use a filtration system to prevent impurities from clogging the high-pressure system or damaging the pump body.

Methods | Description |

Use automatic abrasive feeding system | Maintain stable flow rate and improve cutting consistency |

Use suction cups or vacuum fixation for batch cutting | Quickly change materials and improve positioning efficiency |

Use shared paths in programming | Multiple parts share the same cutting slit, saving time and abrasive |

Set reasonable "piercing points" | Piercing is the slowest step, minimize unnecessary piercing actions |

Personal protective equipment (PPE) must be worn:

Goggles or masks (to prevent splashing)

Soundproof earmuffs (to prevent high noise damage)

Cut-resistant gloves (when handling materials)

Non-slip safety shoes

It is recommended to wear long-sleeved protective clothing.

Equipment must not be operated without training:

Operators must undergo professional training and pass the assessment.

Non-operating personnel are not allowed to approach the machine.

Hands are prohibited from approaching the nozzle area:

Nozzle pressure during cutting is as high as thousands of bar, enough to penetrate the steel plate.

Check the high-pressure system:

No leakage in pipelines and joints.

All connection parts are firm and reliable.

Check whether the nozzle and gem are worn or blocked:

A bad nozzle can cause off-cutting, flying sand, or even bursting.

Check the abrasive system:

The pipeline is unobstructed and there is no agglomeration.

The abrasive barrel cover is tightly closed to prevent moisture absorption.

Ensure that the workpiece is properly fixed:

Prevent material movement or rebound during cutting.

It is strictly forbidden for others to stand near the cutting head:

High-pressure water flow has great destructive power, and accidental injury may be fatal.

It is forbidden to clean the workpiece or adjust the position by hand during the process:

If you need to pause, you should first stop the equipment completely and release the pressure.

Always pay attention to the position of the emergency stop button:

In case of abnormal situation, press the emergency stop immediately.

Do not leave your post during operation:

The cutting process needs to be monitored throughout to prevent the material from lifting or cutting by mistake.

After cutting, the pressure must be relieved:

After turning off the high-pressure pump, it should be confirmed that the pipeline pressure is zero.

After shutting down, turn off the power first, and then clean and maintain:

Remove the residue, abrasive, and water stains in the working area.

It is forbidden to disassemble the pipeline or components under pressure:

All maintenance operations must be carried out after confirming that the power is off and the pressure is off.

Regularly check the high-pressure seals and safety valves:

Improper maintenance may cause pipeline bursts or injuries.

Keep the working area dry, clean and well ventilated. Do not modify cutting parameters or replace accessories without authorization.

It is strictly forbidden to place debris in the high-pressure pump area to avoid hindering heat dissipation or causing fire.

Once abnormal noise, odor or pressure fluctuation is found, the machine should be stopped for inspection immediately.

Recommended equipment:

Safety operation manual

Daily inspection record form

Emergency handling flow chart (posted near the equipment)

High-pressure operation training certificate archived.

Daily inspection of nozzles, mixing tubes and high-pressure seals.

Regularly replace high-pressure pump oil and filters.

Clean the workbench and abrasive collector.

Adequate spare parts inventory (nozzles, gems, seals, etc.).

Record equipment operation logs for fault analysis.

Fault phenomenon | Causes | Solution |

Insufficient water pressure | Pump wear/pressure relief valve problem | Check pump and valve |

Can't cut through | Nozzle blockage/insufficient abrasive | Replace nozzle/refill abrasive |

seam offset | Path setting error/guide rail problem | Reset zero point/repair guide rail |

CNC does not recognize the file | File format error | Convert to compatible format |

Misconceptions | Correct approach |

Not running dry before cutting | A simulation run must be performed first to confirm the path |

Long-term continuous operation | The machine should be stopped regularly to check the nozzle and high-pressure system |

Using water jet to cut soft materials | Soft materials (such as foam) are not suitable for water jet high-pressure cutting |

Ignoring the quality of abrasive particles | Using inferior abrasives will wear out the nozzle and affect efficiency |