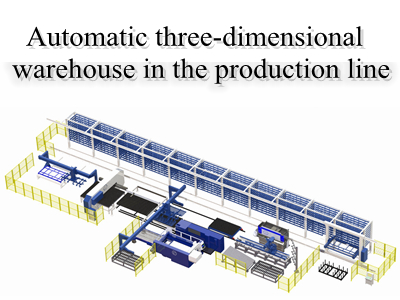

Automatic three-dimensional warehouse is an intelligent access system, which can realize five functions mainly, which are: receipt, inventory, pickup, delivery, and information query.

When the supplier or production workshop provides a large quantity of sheet metal plates, the warehouse management will receive and store these the sheet metal, including raw materials, semi-finished products, finished products, etc.. It will be convenient for processing and production.

The automated intelligent storage will in store the received products in the certain sequence. The high-level automated 3D warehouse can save a lot of floor space for the enterprise, it can maximize the space utilization rate. Compare to the normal warehouse, the intelligent storage capacity is seven to eight times of the normal warehouse. In this way, the company can save a lot of storage costs.

When we need some material from the warehouse, the automatic three-dimensional storage will automatically implement the process of pickup, picking up what we need.

Through the information management of the material, it can accurately record the location of them. It not only prevents errors in the storage process, but also convenient for picking up plates. We don’t need to compare the work piece one by one, it will maximizes the efficiency of picking up them.

The three-dimensional intelligent warehouse will accurately pick up and delivery the metal plate according to the demands, which improves the accuracy of the material delivery.

In addition, the automated intelligent storage has the function of information query, it is very convenient to manage the warehouse anytime and anywhere, and can query the relevant information of the warehouse in real time effectively, including cargo information, operation information, etc.

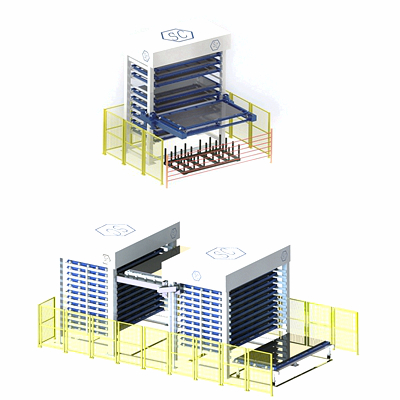

Steel structures for storing sheet metal. There are mainly two kinds shelves: welded type and combined type.

Pallet used to carry metal plates, also known as a workstation appliance.

It’s the automatic access to metal sheets. According to the different structure, there are mainly two kinds: single column type and double column type; according to the service mode, there are mainly three kinds: straight road, curve and transfer car.

The main equipment of the automated intelligent warehouse, which is responsible for transporting the sheets to the stacker or removing the plates from the stacker. There are many types of conveyors, for example: roller conveyors, chain conveyors, lifting platforms, distribution vehicles, hoists, belt conveyors, etc.

It’s an automatic guided car. According to the guiding method, there are mianly two kinds methods: induction-guided trolley and laser-guided trolley.

It’s the control system which drives all equipment of the automated intelligent warehouse . The control mode is mainly based on the field bus.

It is the core of the fully automated intelligent warehouse, which can be networked or integrated with other systems (such as ERP systems, etc.).

Today, we advocate environmental protection and green production. The automated intelligent storage has the advantages of saving land occupation resources, saving production costs, and saving production time, all of which conform to the goal of modern production enterprises.

We, Wuxi Shenchong has hundreds of project experience in automatic three-dimensional warehouse. The automated sheet metal intelligent storage from Wuxi Shenchong consists of material tower, hoist, pallet, loading and unloading system, and material storage management system.

Assembling with a rectangular tube, and the lifting column is processed by the gantry milling machine to ensure the running precision and stability.

The double column lifting mechanism is adopted, and the well-branded motor is used to drive the pallet plate lifting through the double-row chain drive, the tractor on the hoist pulls the hook on one side of the tray to access the storage.

The overall structure is simple and generous, and the equipment is easy to disassemble and carry. With precise positioning, stable operation, fast and flexible functions.

The double-column lifting mechanism is adopted to realize the lifting and lowering of the plates on the tray by the double-row chain driving, and the tractor on the lifting machine pulls the hooks on the side of the tray to realize the ingress and egress. It is accurate in positioning, stable in operation, fast and flexible.

It is welded by rectangular tube, and four hooks are welded on both sides of the tray. The guide post on the tray can realize the initial positioning of the sheet.

It is welded by round bar and can support and position of the whole plate.

It adopts Siemens touch screen industrial computer control, including "plate input, plate output, plate loading, plate unloading, plate input and output record statistics, inventory statistics, inventory warning, fault warning prompts and other interfaces. English interface operation is simple and convenient. It is easy for the operator to learn immediately.

- Using a three-dimensional material warehouse to store plates, saving factory space.

- Adopt intelligent management system to quickly grasp the inventory of plates in real time.

- One-button start, automatic operation.

- Large-capacity storage positions, safe and fast operation.

- The professional team is designed to work in the workshops of most factories.

- Improve work efficiency, reduce the risk of injury, and reduce the labor intensity of staff.

- Customer satisfaction with automated production site.

- On-site 5S management is neat and orderly, and the overall site is convenient for customers to visit.

Automatic three-dimensional warehouse is a new trend storage management development. With the obvious improvement of enterprise logistics efficiency. The intelligent storage system high operation efficiency and intelligent technical will be significantly improved.

Now many large enterprises are beginning to use automated intelligent warehouse. In the future, more and more enterprises will choose intelligent storage system.